Metallographical corrosive, method for eroding copper and method for displaying metallographical organization of copper

A display method and technology of etchant, which is applied in the field of metallographic etchant, copper corrosion and its metallographic structure display, can solve the problems of high safety risk, high oxidation and high corrosion of operators, and achieve good corrosion effect , low corrosiveness and oxidation, low health hazards and environmental pollution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The metallographic etchant provided in the embodiment of the present invention is a mixed solution of water, hydrogen peroxide and ammonia, which has a good corrosion effect on copper or copper alloys, and can make the grain boundaries of the metallographic structure of copper or copper alloys show a good effect.

[0023] The ratio of water, hydrogen peroxide and ammonia water in the metallographic etchant is 2:(1-2):3. The metallographic etchant is suitable for the corrosion of high-purity copper, especially has a good corrosion effect on 6N copper; it is also suitable for low-purity copper.

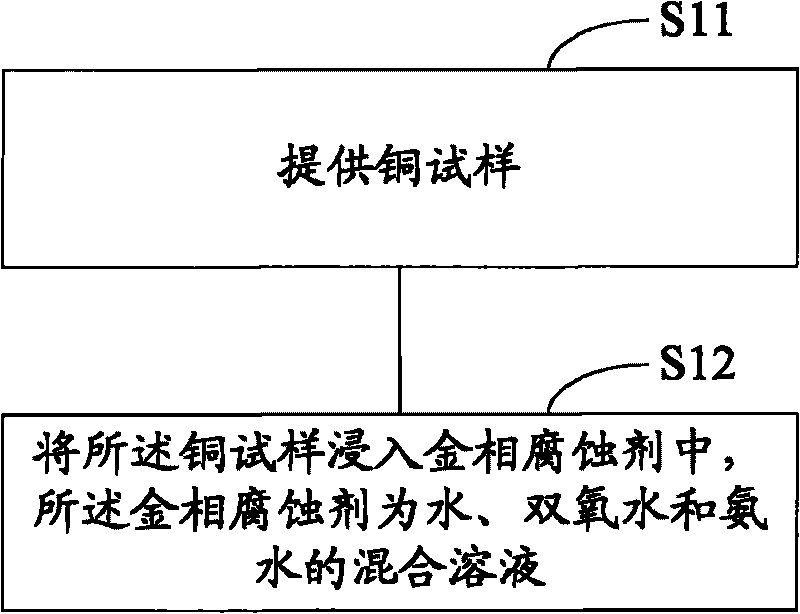

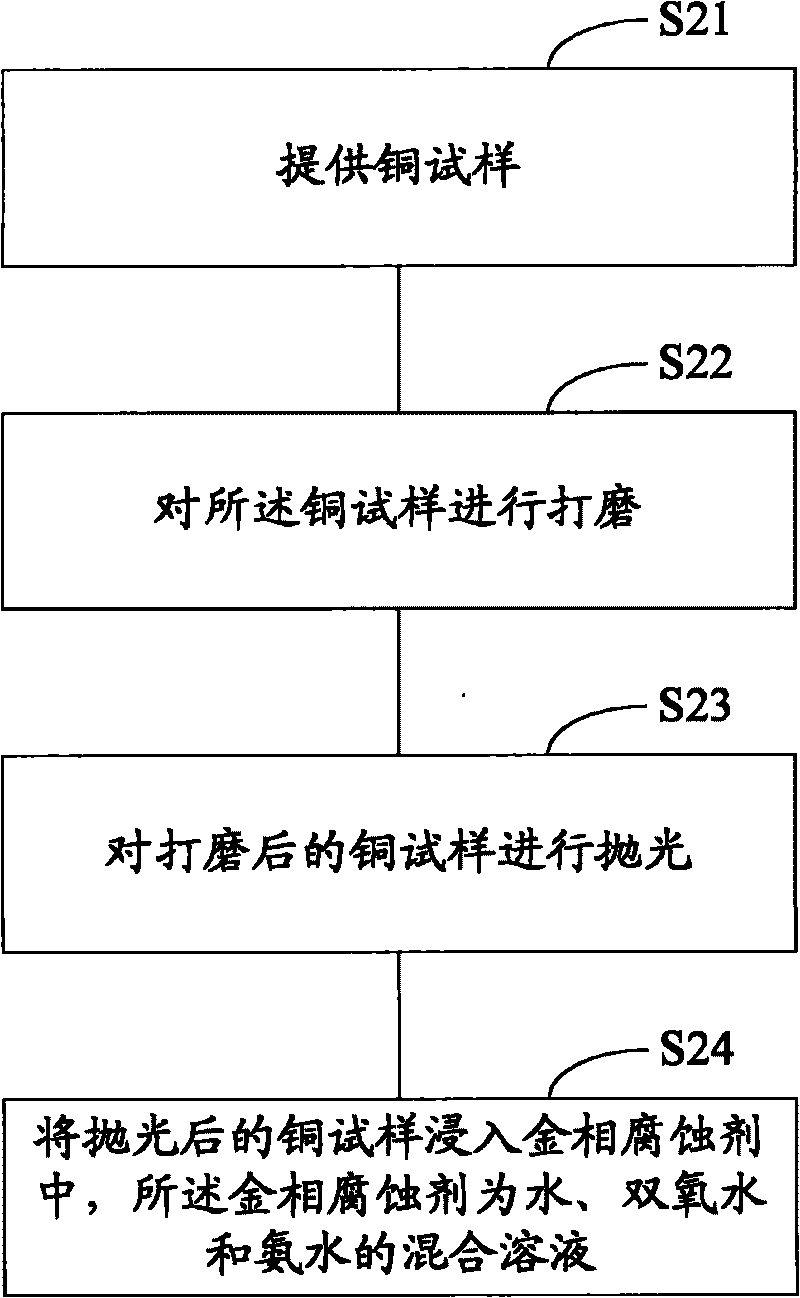

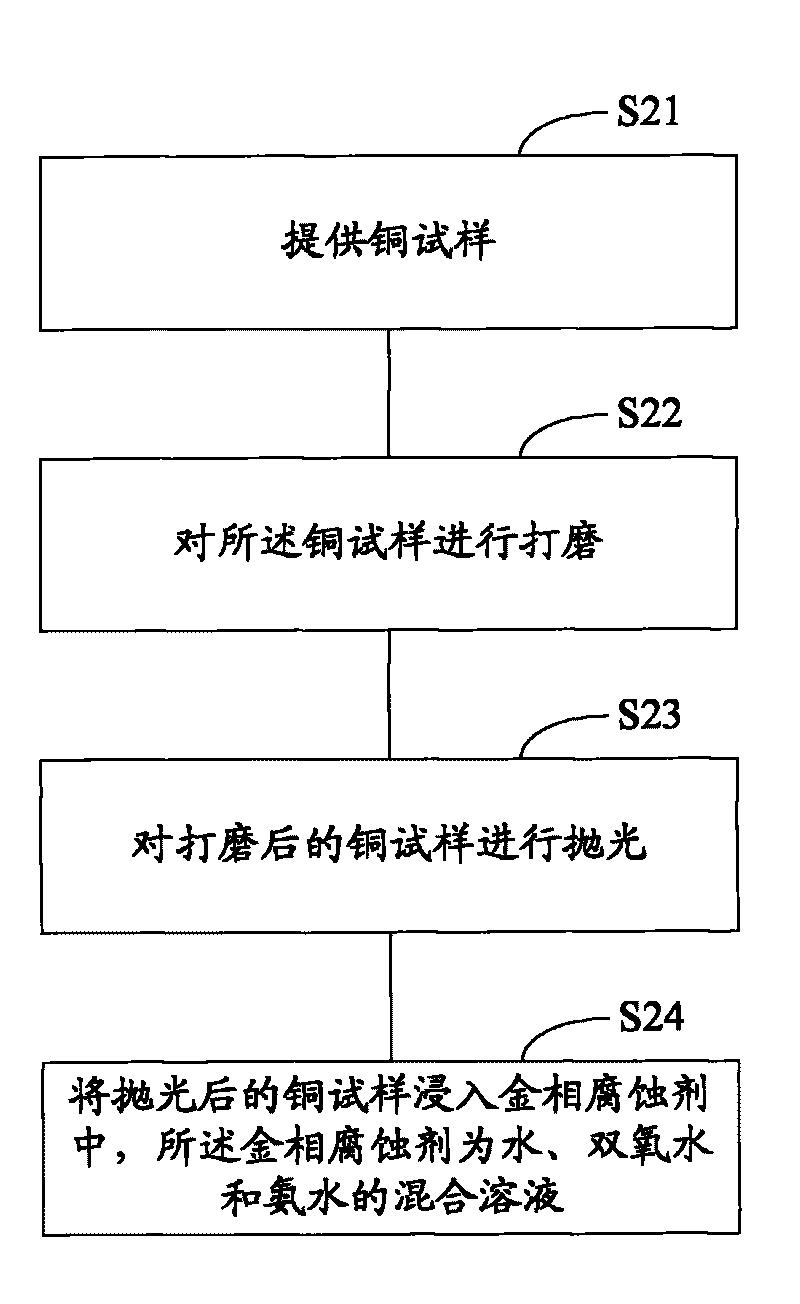

[0024] Both metals and alloys are polycrystalline, that is, they are composed of grains. Etching of metals and alloys with metallographic etchants reveals the grain boundaries of metal and alloy grains. The copper corrosion method of the embodiment of the present invention is as figure 1 As shown, it includes: step S11, providing a copper sample; step S12, immersing the copper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com