ACFM intelligent visual defect detection system

A defect and intelligent technology, which is applied in the field of ACFM defect intelligent visual detection system device, can solve problems such as low efficiency, low level of visualization, and difficulty in improving the accuracy of quantitative analysis, and achieve low cost, simple method, and improved intelligence and visualization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below by means of drawings and examples.

[0024] The ACFM defect intelligent visual detection system is used to detect cracks on the surface of low carbon steel sheets that are 40mm long, 8mm deep, and 1mm wide.

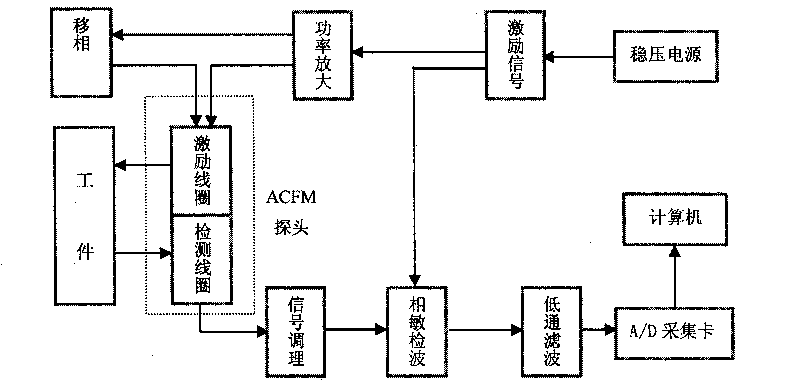

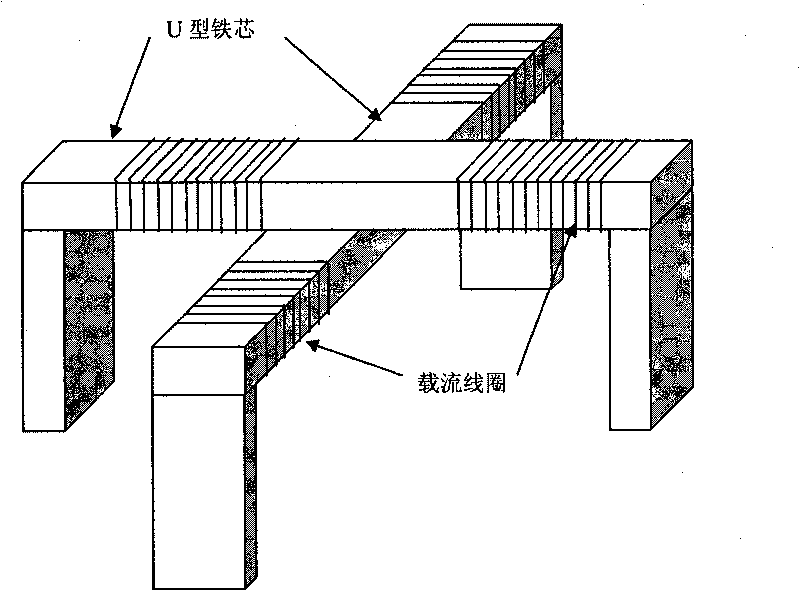

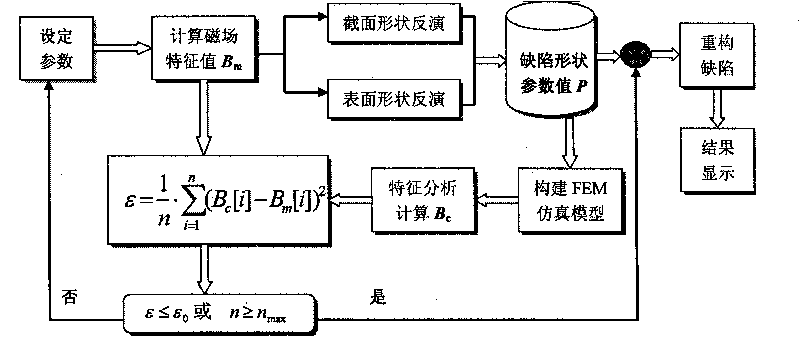

[0025] Defect intelligent visual detection process. The composition of the ACFM defect intelligent visual detection system is as follows: figure 1 As shown, it is mainly composed of a power supply, an excitation signal generator, a power amplifier circuit, a phase shifting circuit, an excitation probe, a detection probe, a signal conditioning circuit, an A / D acquisition card, and an intelligent defect detection software based on LabVIEW. The regulated power supply supplies power to the signal generator composed of the voltage-controlled function generator ICL8038 and the RF follower, and the signal generator provides a frequency of 6KH Z A sine wave with an amplitude of 1V is used as an excitation signal, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com