Method for preparing battery-grade lithium dihydrogen phosphate

A lithium dihydrogen phosphate, battery-level technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of inapplicable lithium iron phosphate production, uneven product particle size, complicated process, etc., and achieve shortened crystallization Effects of time, small particle size, and inhibition of growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

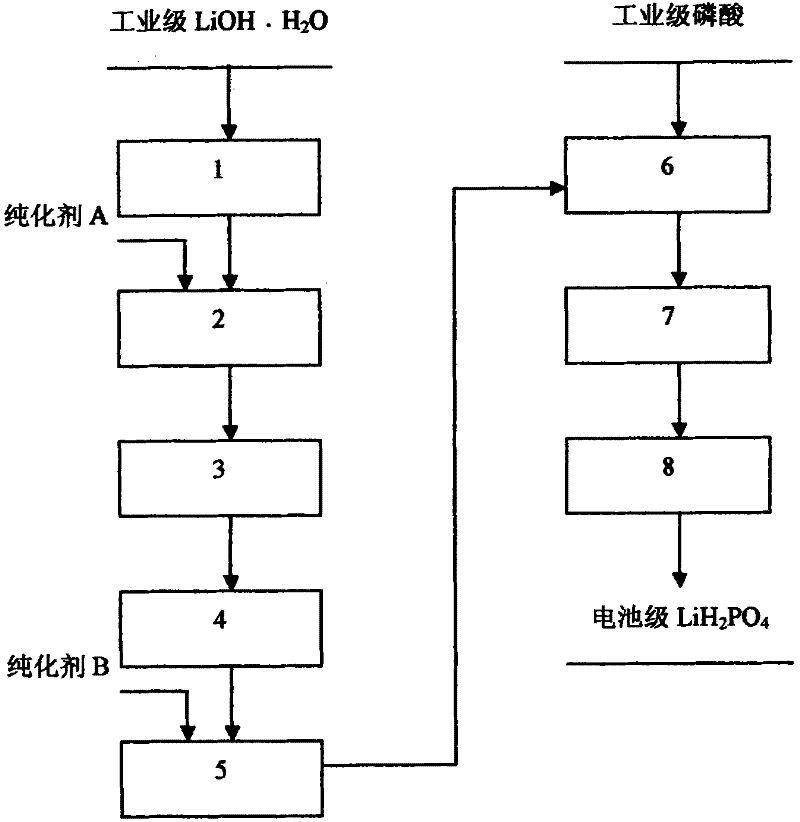

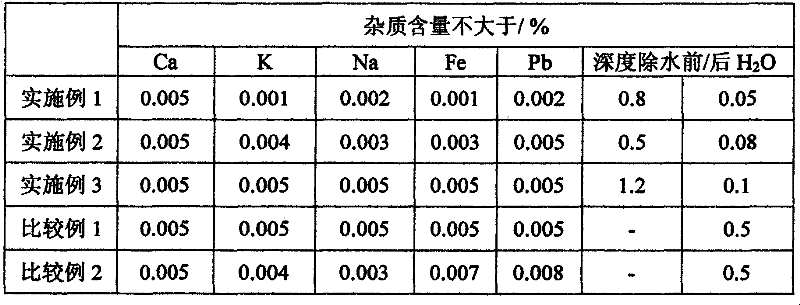

[0030] Weigh industrial grade LiOH·H 2 O 428.3g, be dissolved in deionized water, filter to remove insoluble matter, measure wherein Na + 、K + According to the corresponding stoichiometric ratio, add the purifying agent lithium sulfate, cool the LiOH solution with lithium sulfate to a certain temperature, filter and remove the insoluble matter, and obtain a colorless and clear solution, and measure the SO in the solution. 4 2- According to the stoichiometric ratio, the purifying agent barium hydroxide octahydrate was added to the solution, and the insoluble matter was removed by filtration to obtain the refined LiOH solution. Adjust the concentration of LiOH to 10%, and put it in the high-level tank, weigh 1164.5g of industrial phosphoric acid, adjust its concentration to about 40%, add the LiOH solution to the phosphoric acid dropwise, and the feeding time is 1 hour. After the reaction, the pH value of the solution is 2.5, and the solution is colorless and transparent, the...

Embodiment 2

[0032] Weigh industrial grade LiOH·H 2 O 441.2g, be dissolved in deionized water, filter to remove insoluble matter, measure wherein Na + 、K + According to the corresponding stoichiometric ratio, add dilute sulfuric acid as a purifying agent, cool down the LiOH solution added with dilute sulfuric acid to a certain temperature, filter to remove insoluble matter, and obtain a colorless and clear solution, and measure SO in the solution 4 2- content, add barium hydroxide octahydrate to the solution according to the stoichiometric ratio, and filter to remove insoluble matter to obtain LiOH refined solution. Adjust the concentration of LiOH to 8%, and place it in the high-level tank, weigh 1176g of industrial phosphoric acid, adjust its concentration to about 50%, add the LiOH solution dropwise to the phosphoric acid, and the feeding time is 1.5 hours. After the reaction, the pH of the solution is 2. The solution is colorless and transparent. Spray-dry the colorless and transpar...

Embodiment 3

[0034] Weigh industrial grade LiOH·H 2 O 432.6g, be dissolved in deionized water, filter to remove insoluble matter, measure wherein Na + 、K + According to the corresponding stoichiometric ratio, add the purifying agent lithium sulfate, cool the LiOH solution with lithium sulfate to a certain temperature, filter and remove the insoluble matter, and obtain a colorless and clear solution, and measure the SO in the solution. 4 2-content, add barium hydroxide octahydrate to the solution according to the stoichiometric ratio, and filter to remove insoluble matter to obtain LiOH refined solution. Adjust the concentration of LiOH to 5%, and place it in the high-level tank, weigh 1187g of industrial phosphoric acid, adjust its concentration to about 60%, add the LiOH solution dropwise to the phosphoric acid, and the feeding time is 2 hours. After the reaction, the pH of the solution is 3.5, and the solution is colorless and transparent, spray-dry the colorless and transparent solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com