Crack resistance amorphous acid-proof pouring material, crack resistance acid-proof heat preservation protective layer and manufacturing method thereof

The technology of acid-resistant castable and protective layer is applied in the manufacture of the above-mentioned crack-resistant acid-resistant thermal insulation protective layer, and the field of crack-resistant acid-resistant thermal insulation protective layer can solve the problems of reducing thermal insulation performance, unable to prevent corrosion of equipment shell, and increasing thermal conductivity of thermal insulation layer. , to prevent the expansion of micro-cracks, good thermal insulation performance, good crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

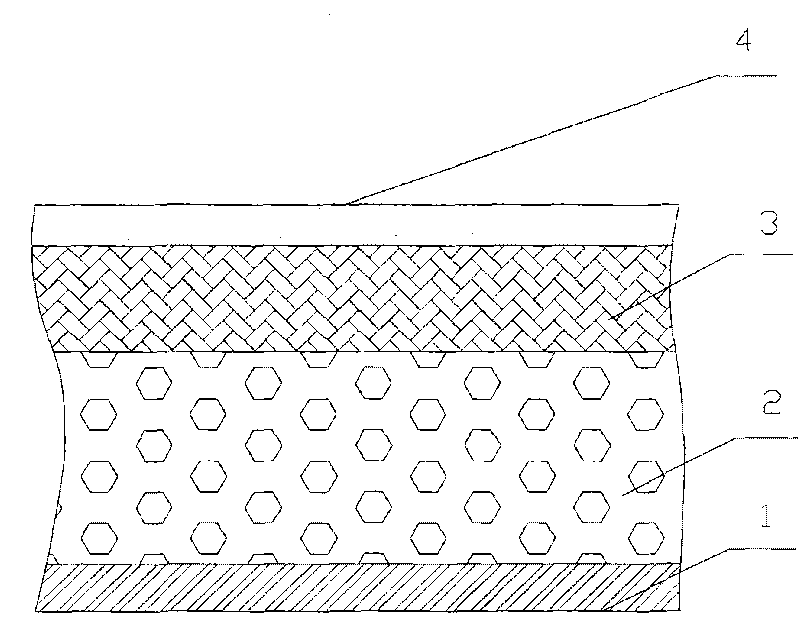

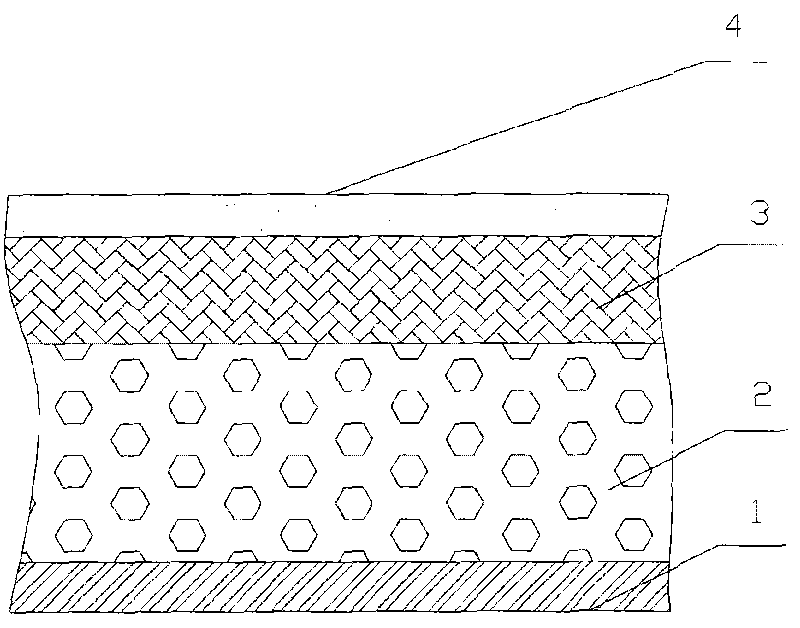

Image

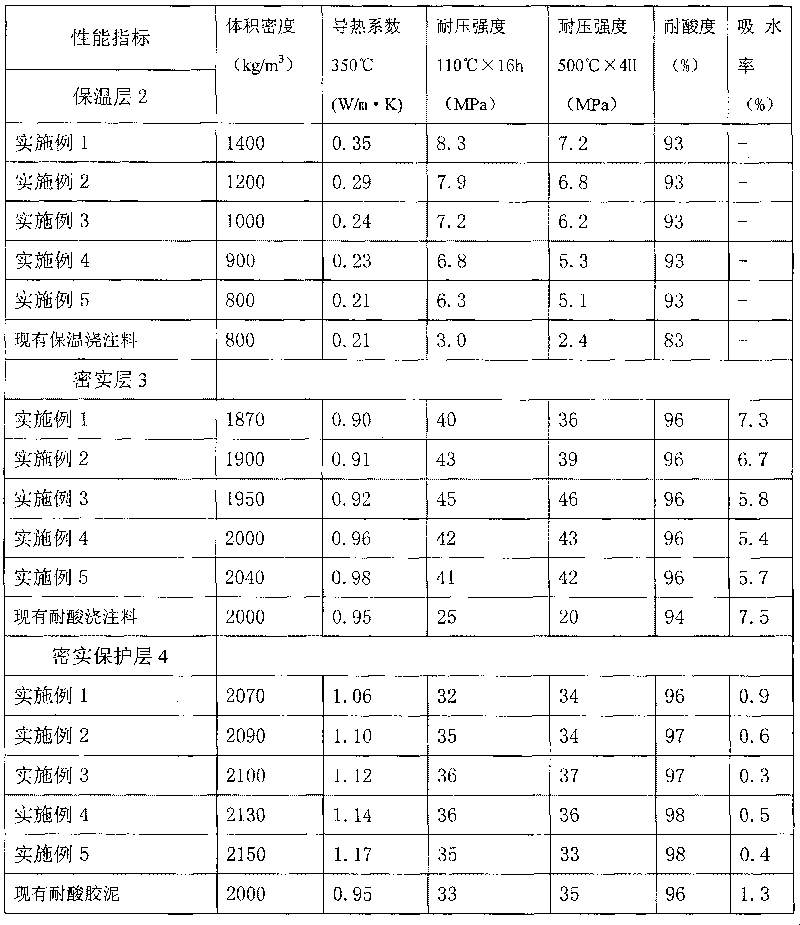

Examples

Embodiment 1

[0050] Embodiment 1: A kind of amorphous acid-resistant thermal insulation material with anti-cracking ability, the raw material is:

[0051] (1) Water glass: the modulus is M2.6-3.0;

[0052] (2) Powdered sodium fluorosilicate or condensed aluminum phosphate: the particle size is less than 100 mesh;

[0053] (3) Porous ceramsite (irregular granular shape) fired with clay: the particle size is 5-40mm;

[0054] (4) Expanded perlite particles: particle size is 1-5mm;

[0055] (5) Diabase powder: the particle size is less than 200 mesh;

[0056] (6) Glass fiber yarn: diameter 0.2-1.5mm, length: 15-50mm.

[0057] The ratio of the above materials is 1 part (by weight) of water glass, 1 part of diabase powder, 0.17 of powdery sodium fluorosilicate, or 0.07 of condensed aluminum phosphate, 2 parts of irregular granular clay porous ceramsite, and expanded perlite particles 0.3, glass fiber yarn 0.02.

Embodiment 2

[0058] Embodiment 2: raw material composition is identical with embodiment 1, and each material proportioning is 1 part (weight) with water glass, powdery sodium fluorosilicate is 0.17, or condensed aluminum phosphate 0.07, diabase powder 2, irregular particle Clay porous ceramsite 3, expanded perlite particles 0.6, glass fiber yarn 0.03.

Embodiment 3

[0059] Embodiment 3: raw material component is identical with embodiment 1, and each material proportioning is 1 part (weight) with water glass, powdery sodium fluorosilicate is 0.16, or condensed aluminum phosphate 0.07, diabase powder 2.5, irregular Granular clay porous ceramsite 3.5, expanded perlite particles 0.8, glass fiber yarn 0.04.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com