Preparation method for feed additive dihydropyridine

A feed additive, dihydropyridine technology, applied in the field of medicine and chemical industry, can solve the problems of short reaction time, high energy consumption and high cost, and achieve the effects of short reaction time, low cost and high benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

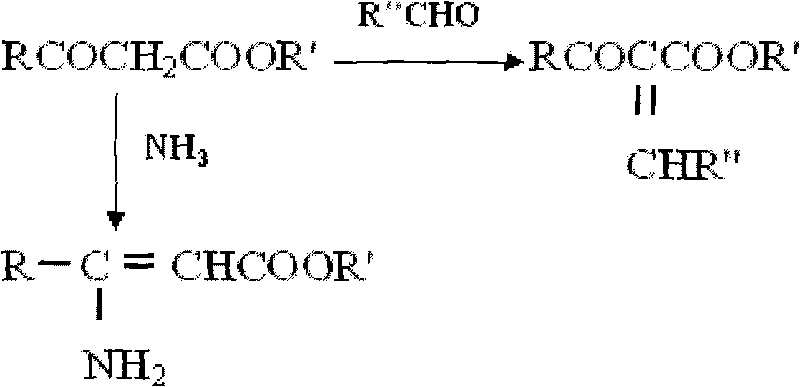

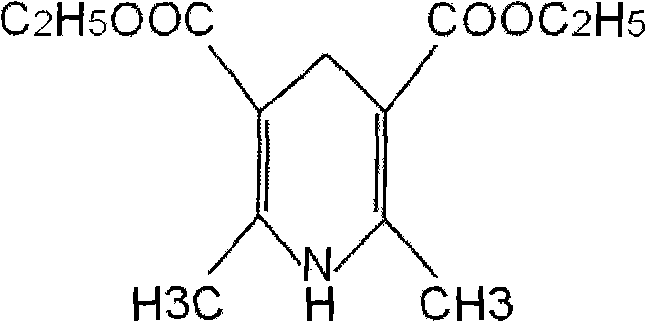

Method used

Image

Examples

example 1

[0019] A kind of preparation method of feed additive dihydropyridine, its steps are:

[0020] 1. Put 1 mole of ethyl acetoacetate and 1 mole of formaldehyde with a concentration of 40% by weight into a reaction kettle equipped with a reflux condenser, stir and dissolve at 25 or 28 or 30 or 32 or 34 or 35 ° C, add 95% ethanol with a percentage concentration of 1 times the weight ratio, controlled temperature at 60° C., and reacted for 1 hour to obtain liquid A.

[0021] 2. Put 1 mole of ethyl acetoacetate and 2 moles of ammonium bicarbonate into a reaction kettle equipped with a reflux condenser, add 95% ethanol with a weight ratio of 1 times, control the temperature at 60°C, and react for 1 hour to obtain liquid B .

[0022] 3. Put liquid A and liquid B into a reaction kettle equipped with a reflux condenser, add 50 grams of sodium hydroxide, control the reaction temperature at 60°C, react for 1 hour, cool and precipitate crystals, filter, and dry the filter cake at 80°C for ...

example 2

[0024] A kind of preparation method of feed additive dihydropyridine, its steps are:

[0025] 1. Put 1 mole of ethyl acetoacetate and 1.5 moles of formaldehyde with a concentration of 40% by weight into a reaction kettle equipped with a reflux condenser, stir and dissolve at 25 or 27 or 39 or 31 or 33 or 35 ° C, add the weight ratio 1.5 times the percentage concentration of 95% ethanol, control the temperature at 65°C, and react for 1.5 hours to obtain liquid A.

[0026] 2. Put 1 mole of ethyl acetoacetate and 2.5 moles of ammonium bicarbonate into a reaction kettle equipped with a reflux condenser, add 95% ethanol with a weight ratio of 1.5 times, control the temperature at 65° C., and react for 1.5 hours to obtain B liquid.

[0027] 3. Put liquid A and liquid B into a reaction kettle equipped with a reflux condenser, add 60 grams of sodium hydroxide, control the reaction temperature at 65°C, react for 1.5 hours, cool and precipitate crystals, filter, and dry the filter cake...

example 3

[0029] A kind of preparation method of feed additive dihydropyridine, its steps are:

[0030] 1. Put 1 mole of ethyl acetoacetate and 2 moles of formaldehyde with a concentration of 40% by weight into a reaction kettle equipped with a reflux condenser, stir and dissolve at 25 or 26 or 29 or 31 or 33 or 35 ° C, add the weight ratio 2 times the percentage concentration of 95% ethanol, controlled temperature 70°C, reacted for 1.5 hours to obtain liquid A.

[0031] 2. Put 1 mole of ethyl acetoacetate and 3 moles of ammonium bicarbonate into a reactor equipped with a reflux condenser, add 95% ethanol with a percentage concentration of 2 times the weight ratio, control the temperature at 70° C., and react for 1.5 hours to obtain B liquid.

[0032] 3. Put liquid A and liquid B into a reaction kettle equipped with a reflux condenser, add 70 grams of sodium hydroxide, control the reaction temperature at 70°C, react for 2 hours, cool and precipitate crystals, filter, and dry the filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com