Compound pre-mixed feed for animal and bird

A compound premix and premix technology, applied in animal husbandry, animal feed, animal feed, etc., can solve problems such as poor production performance, low egg production rate, and uneven weight of chicken flocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: when described premix is applicable to the 1% premix of laying hen laying early stage, contain Vit A 330g, Vit D in every kilogram of composite premix 3 7.5g, Vit E 1.5g, Vit K 3 0.26g, Vit B 1 0.18g, Vit B 2 0.5g, Vit B 6 0.20g, Vit B 12 0.0009g, pantothenic acid 0.9g, niacin 4.2g, folic acid 0.08g, biotin 0.007g, choline chloride 30g, ferrous sulfate heptahydrate 32.34g, zinc sulfate heptahydrate 35.24g, copper sulfate pentahydrate 1.33g, pentahydrate Manganese sulfate water 43.86g, potassium iodide 0.12g, sodium selenite 0.04g, the rest is corn gluten powder and stone powder;

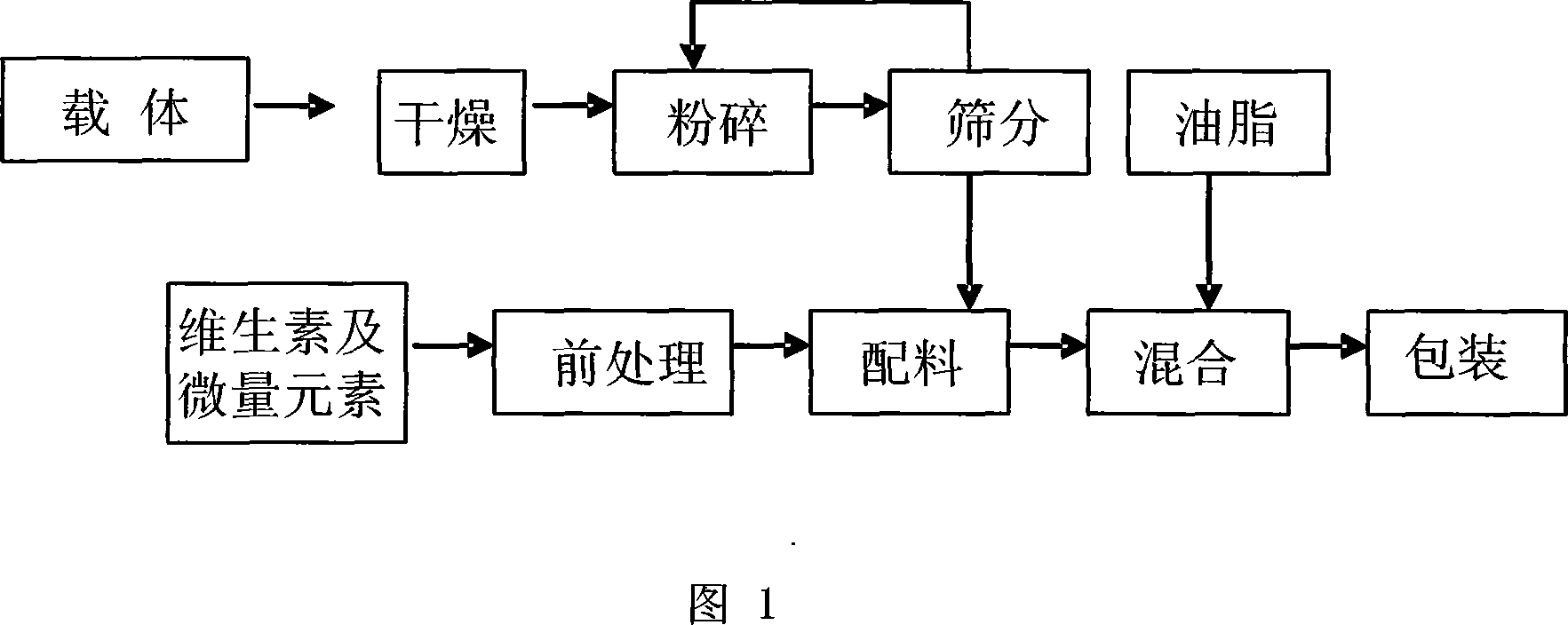

[0022] Above-mentioned proportioning is made the 1% premix of laying hen laying early stage according to following technological steps (production technological process as shown in Figure 1):

[0023] (1) Grinding and sieving the multivitamins, inorganic salts, lysine and other components in the proportioning ratio, so that the sieved particle size reaches 30-80 mesh...

Embodiment 2

[0029] Embodiment 2: when described premix is applicable to the 1% premix of laying hen laying eggs I period, contain Vit A 300g, Vit D in every kilogram of composite premix 3 6.25g, Vit E 1.7g, Vit K 3 0.20g, Vit B 1 0.15g, Vit B 2 0.45g, Vit B 6 0.26g, Vit B 12 0.0010g, pantothenic acid 0.8g, niacin 3.0g, folic acid 0.07g, biotin 0.005g, choline chloride 36g, ferrous sulfate heptahydrate 32.34g, zinc sulfate heptahydrate 35.24g, copper sulfate pentahydrate 1.33g, pentahydrate Manganese sulfate water 39.47g, potassium iodide 0.14g, sodium selenite 0.04g, the rest is corn gluten powder and stone powder;

[0030] The preparation method is the same as in Example 1.

Embodiment 3

[0031] Embodiment 3: when described premix is applicable to the 1% premix of laying hen laying eggs II stage, contain Vit A 270g, Vit D in every kilogram of composite premix 3 30g, Vit E 0.8g, Vit K 3 0.16g, Vit B 1 0.10g, Vit B 2 0.4g, Vit B 6 0.15g, Vit B 12 0.0007g, pantothenic acid 0.7g, niacin 2.8g, folic acid 0.05g, biotin 0.003g, choline chloride 47g, ferrous sulfate heptahydrate 29.85g, zinc sulfate heptahydrate 35.24g, copper sulfate pentahydrate 1.33g, pentahydrate Manganese sulfate water 39.47g, potassium iodide 0.10g, sodium selenite 0.04g, and the rest are corn gluten powder and stone powder.

[0032] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com