Coal slime drying device

A drying device and coal slime technology, applied in heating devices, drying solid materials, local agitation dryers, etc., can solve problems such as high requirements for operation and management, difficulty in feeding materials, and high failure rate of equipment, and achieve low requirements for operation and management , drying operation cost, energy saving, and low drying operation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

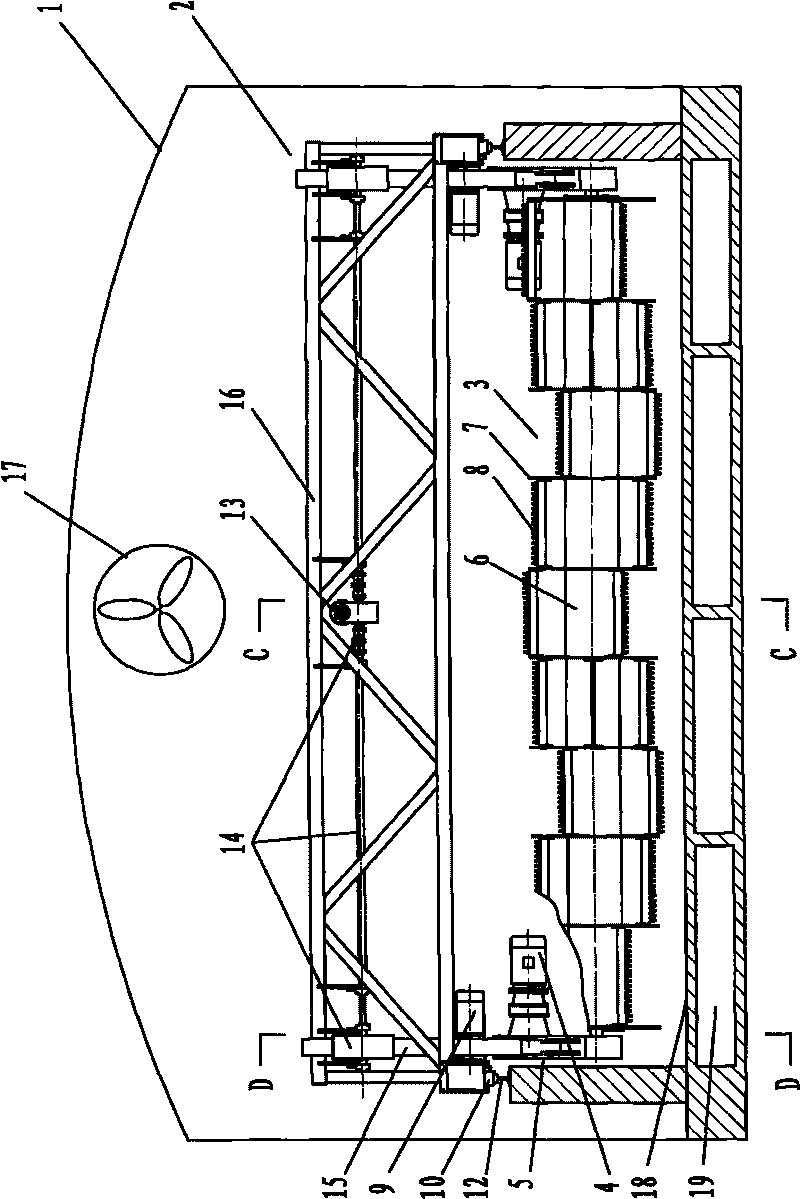

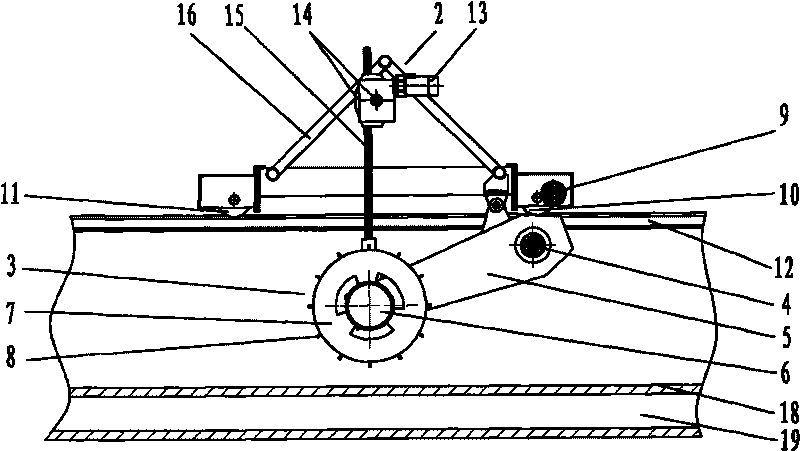

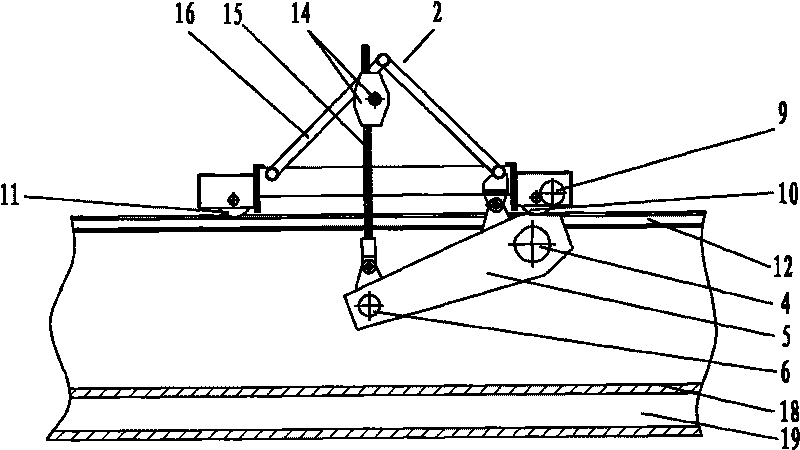

[0015] Such as figure 1 , 2 As shown in and 3, a coal slime drying device proposed by the present invention includes a solar greenhouse 1 and a bridge-type turning and throwing device 2, and the bridge-type turning and throwing device 2 is arranged in the solar greenhouse 1. The bridge type throwing device 2 includes a throwing mechanism, a walking mechanism, a lifting mechanism, and a frame. The throwing mechanism includes a throwing wheel 3, a throwing motor 4, and a transmission device 5 for turning over. The throwing wheel 3 is made up of a hollow tube 6, an annular plate 7 and a scraper 8, and the relationship is as follows: the hollow tube 6 is equipped with an annular plate 7 at a certain distance, and several scrapers 8 are arranged between adjacent annular plates. The scrapers on both sides of a circular plate are staggered at a certain angle. In this embodiment, three scrapers are evenly arranged between every two adjacent annular plates, and the scrapers on both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com