Positive plate of lead-acid accumulator

A lead-acid battery, positive plate technology, applied in the direction of lead-acid battery electrodes, etc., can solve the problems of long charging time, softening and falling off, and decreasing active material density, so as to enhance structural strength and dimensional stability, and improve creep resistance. , the effect of reducing the chance of swelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

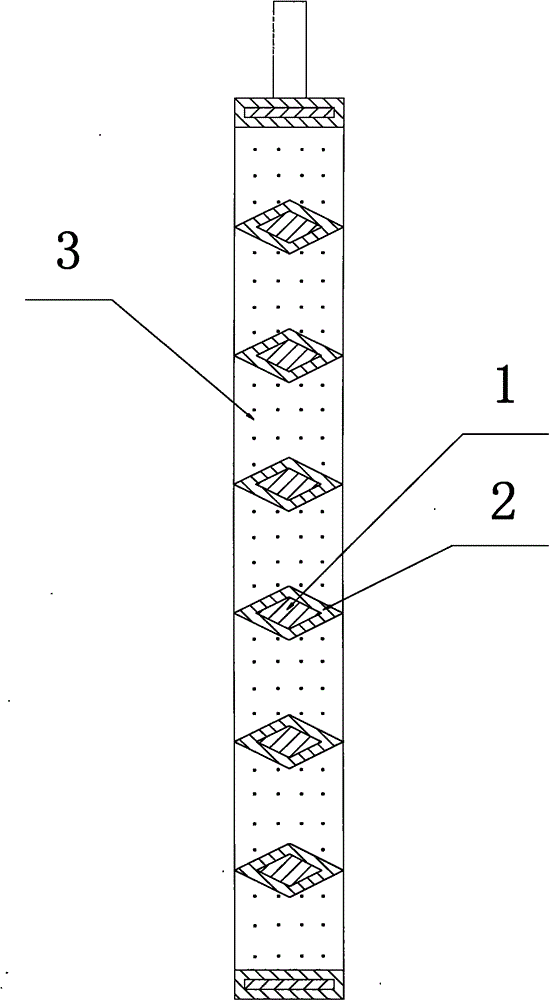

[0027] Example: Combine figure 1 As shown, the positive plate of this lead-acid battery provided in this embodiment includes a positive grid 1, and the surface of the positive grid 1 is coated with a carbon fiber composite base layer 2 made of a mixture of carbon fiber and a corresponding matrix, and in the The carbon fiber composite base layer 2 is then coated with a positive electrode active material 3 made of lead paste, and the positive electrode active material 3 fills and fills the grid of the positive electrode grid 1 as in the prior art. The carbon fiber composite base layer 2 described in the present embodiment is that the component weight percent is: carbon fiber 35%, graphite fiber 20%, anisotropic graphite 20%, carboxymethyl cellulose 12%, polytetrafluoroethylene 15% The mixture is made into a slurry, which is coated on the surface of the positive electrode grid 1 and then dried and solidified. And the total weight of the above-mentioned mixture accounts for 0.002...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com