Processing method for interturn insulation of high-voltage motor pole coil

A magnetic pole coil, inter-turn insulation technology, applied in laying solid insulation and other directions, can solve the problems of poor heat dissipation, waste of raw materials, and inter-turn insulation thickness, etc., to reduce production costs, improve power generation, and good electrical performance and mechanical strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

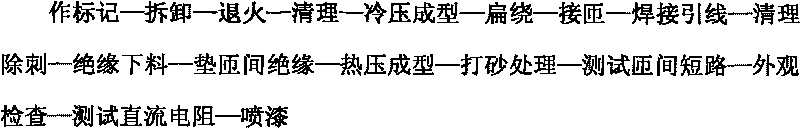

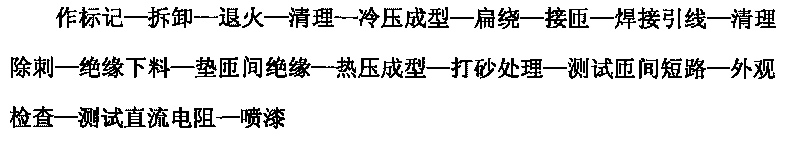

[0023] A high-voltage motor magnetic pole coil turn-to-turn insulation processing method, which is characterized by: including the following process, numbering and marking the paired magnetic pole cores and magnetic pole coils, disassembling, annealing, cleaning, forming, flat winding, and Turn-connection, insulation blanking, inter-turn insulation process to realize the inter-turn insulation of the magnetic pole coil, and set it with the magnetic pole core according to the number.

[0024] When numbering and marking the magnetic pole coils, after increasing the number of turns of the copper bar and marking the position of the original lead wire, the number of turns of the copper bar is welded to ensure that the position and size of the original lead wire remain unchanged.

[0025] When the pole coil is formed, the insulation of the pole body of the pole coil and the heat-pressing structure of the pole support plate are adopted to ensure the heat-pressing quality of the pole co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com