Transformer-free inverter

A technology of transformers and inverters, applied in the field of transformerless inverters, which can solve the problem of increasing the step-up ratio of the front-stage DC/DC boost circuit and the difficulty of design, the inability to improve the power generation quality and efficiency of the inverter, and increasing the front-end The number of series-connected DC input sources and other issues can be solved to achieve the effects of reducing copper loss and magnetic loss, simple structure, and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

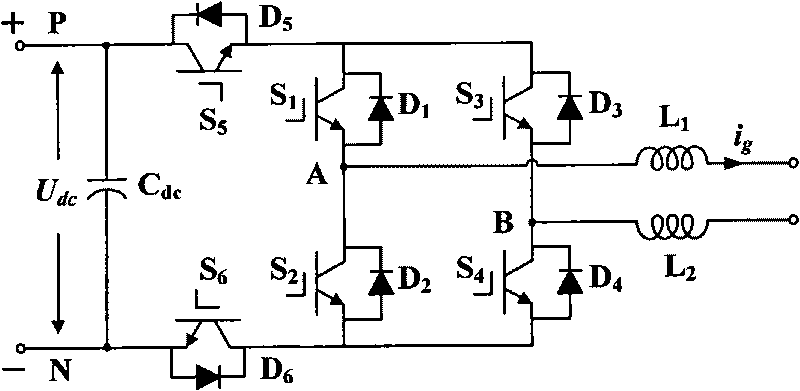

[0018] See attached figure 1 , the transformerless inverter of the present invention includes an input capacitor C dc , six power switch tubes, six anti-parallel diodes, two filter inductors L 1 and L 2 ; The first power switch tube S 1 , the first anti-parallel diode D 1 , the second power switch tube S 2 , the second antiparallel diode D 2 , the third power switch tube S 3 , the third anti-parallel diode D 3 and the fourth power switch S 4 , the fourth anti-parallel diode D 4 together constitute a full-bridge structure circuit, the fifth power switch tube S 5 The drain, input capacitance C dc The positive terminal of the input DC terminal is connected to the positive terminal of the input DC terminal, and the fifth power switch tube S 5 source of the first power switch S 1 The drain of the third power switch S 3 connected to the drain of the first power switch S 1 source of the second power switch S 2 The drain with the first filter inductor L 1 Connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com