Long bag pulse spraying dust collector capable of preventing bag explosion

A technology of explosion-proof bags and dust collectors, applied in the field of dust collectors, can solve the problems of uneven wear of airflow distribution filter bags, failure to give full play to the advantages of pulse jet cleaning, poor sealing performance, etc., to avoid uneven air intake and Filter, reduce being sucked into the dust collector, and overcome the effect of too fast rising speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

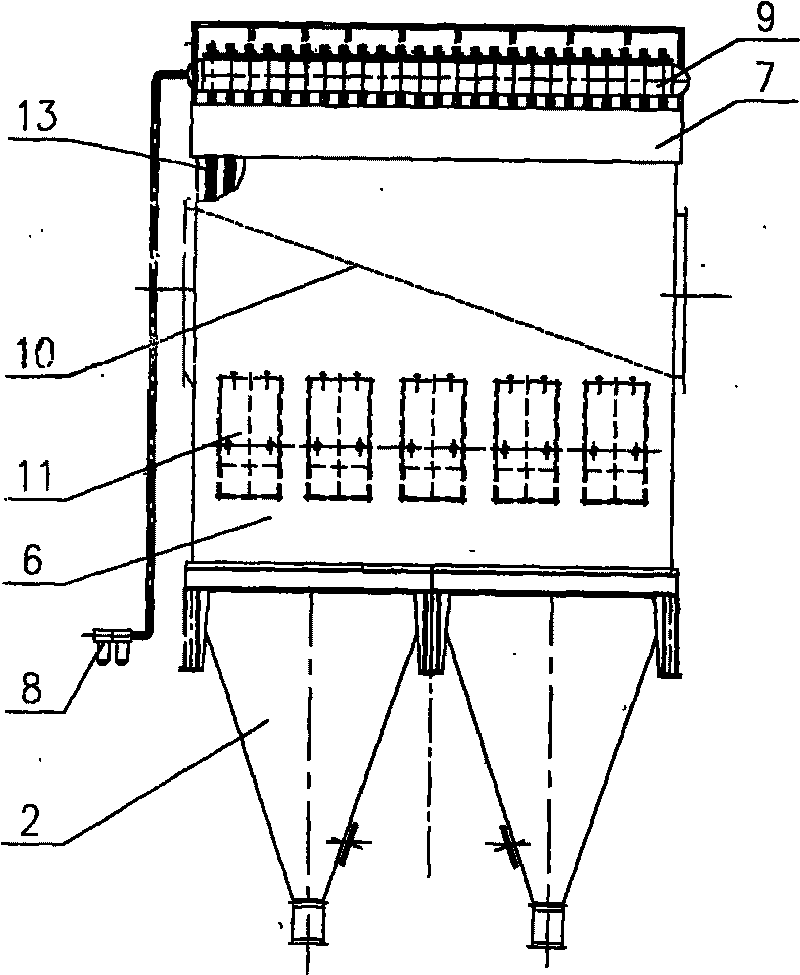

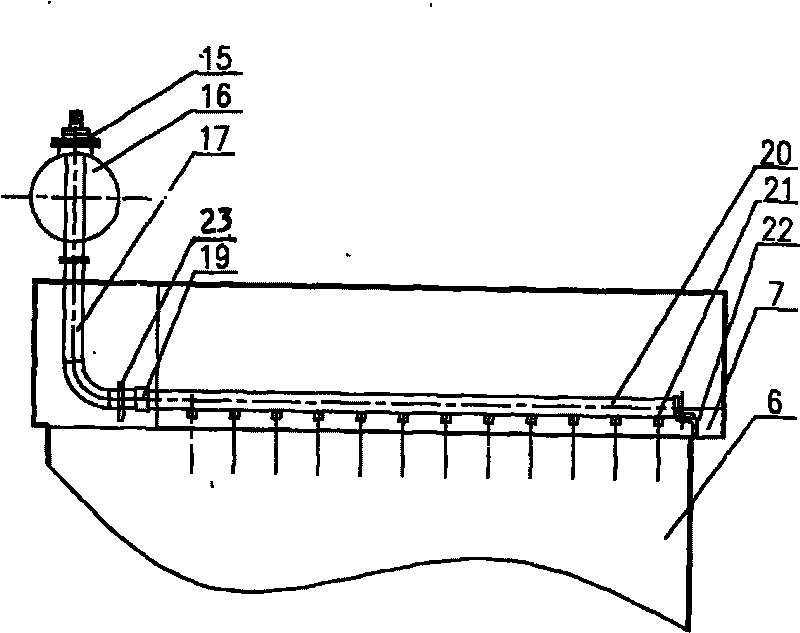

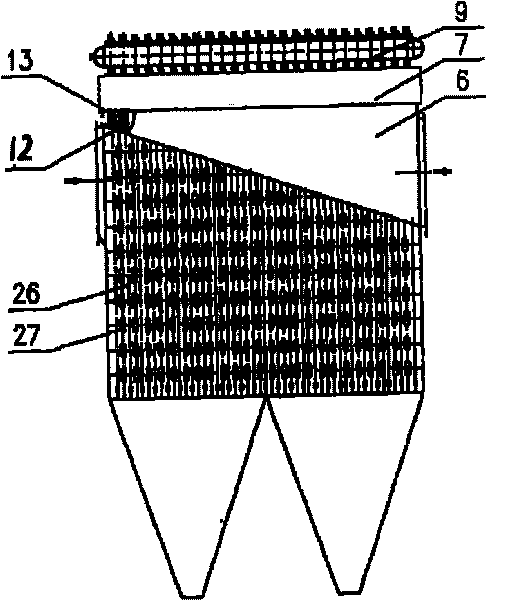

[0019] Such as figure 1 , 3 As shown in , 4, the long bag pulse jet explosion-proof bag dust collector includes the ash hopper 2 arranged at the bottom of the casing, and is arranged in a plurality of bag chambers 6 composed of wall panels, bag cages 12, filter bags and chamber partitions in the casing , the clean air chamber 7 formed between the flower plate and the top of the box body and the air inlet and outlet ducts formed by the air duct partition, the deflector 10 arranged obliquely in the air duct, and the air guide plate 10 arranged at the bottom of the filter bag by The explosion-proof door seat shell welded on the front wall plate 14 of the dust collector, the explosion-proof door cover whose upper part is hinged to the dust collector wall plate, and the counterweight hammer set at the outer lower part of the door cover through a pressure rod pressure explosion-proof device 11, and the injection system 9 composed of pulse valve, air bag, air pipe, injection pipe an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com