Single-dielectric-layer off-line coated low-emissivity glass

A low-emissivity glass and dielectric layer technology, which is applied in the fields of glass manufacturing and energy conservation and environmental protection, can solve the problems of high production costs, achieve the effects of increased productivity, improved stability, and high deposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

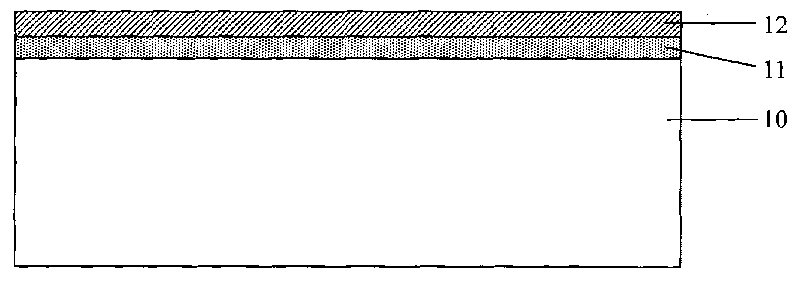

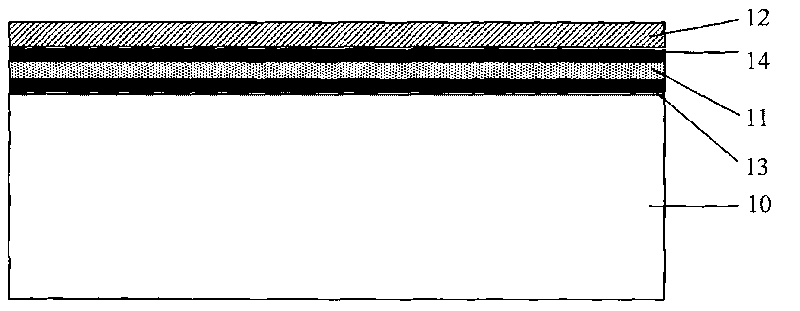

Method used

Image

Examples

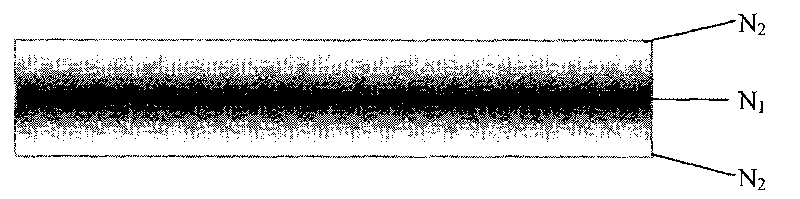

Embodiment 1

[0018] Embodiment 1: low-emissivity glass, its structure is: glass plate, 10 nanometer thick silver layer, 11 nanometer thick dielectric layer. The dielectric layer is made of silicon-oxygen film, the part with the highest silicon component has a refractive index of 4.0, and the part with the lowest silicon component has a refractive index of 1.5. The visible light transmittance of the low-emissivity glass exceeds 75%, the sunlight transmittance exceeds 55%, and the radiation coefficient is less than 0.05.

Embodiment 2

[0019] Embodiment 2: low-emissivity glass, its structure is: glass plate, 10 nanometers thick silver layer, 12 nanometers thick dielectric layer. The dielectric layer is made of silicon-aluminum-nitrogen thin film, the atomic number ratio between silicon and aluminum is 15:1, the part with the highest silicon-aluminum component has a refractive index of 3.8, and the part with the lowest silicon component has a refractive index of 2.0. The visible light transmittance of the low-emissivity glass exceeds 80%, the sunlight transmittance exceeds 60%, and the radiation coefficient is less than 0.05.

Embodiment 3

[0020] Embodiment 3: low-emissivity glass, its structure is: glass plate, 10 nanometer thick silver layer, 20 nanometer thick dielectric layer. The dielectric layer is made of silicon oxygen nitrogen film, the part with the highest silicon component has a refractive index of 3.0, and the part with the lowest silicon component has a refractive index of 1.6. The visible light transmittance of the low-emissivity glass exceeds 80%, the sunlight transmittance exceeds 60%, and the radiation coefficient is less than 0.05.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com