Lubricant film thickness measuring instrument

A lubricant film, thickness measurement technology, applied in the field of measurement instruments, can solve the problems of low measurement accuracy and stability, and achieve the effects of improving lubrication effect, improving service life, and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

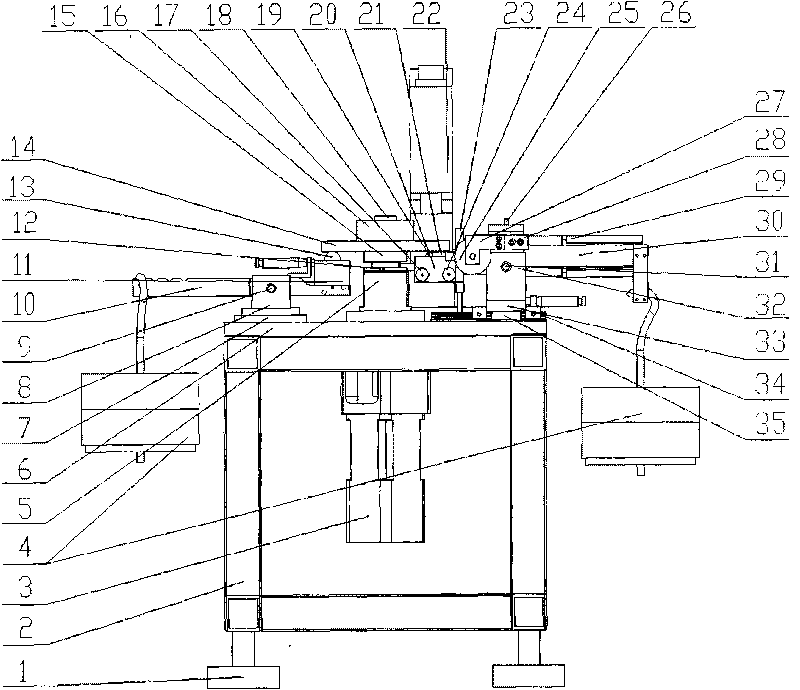

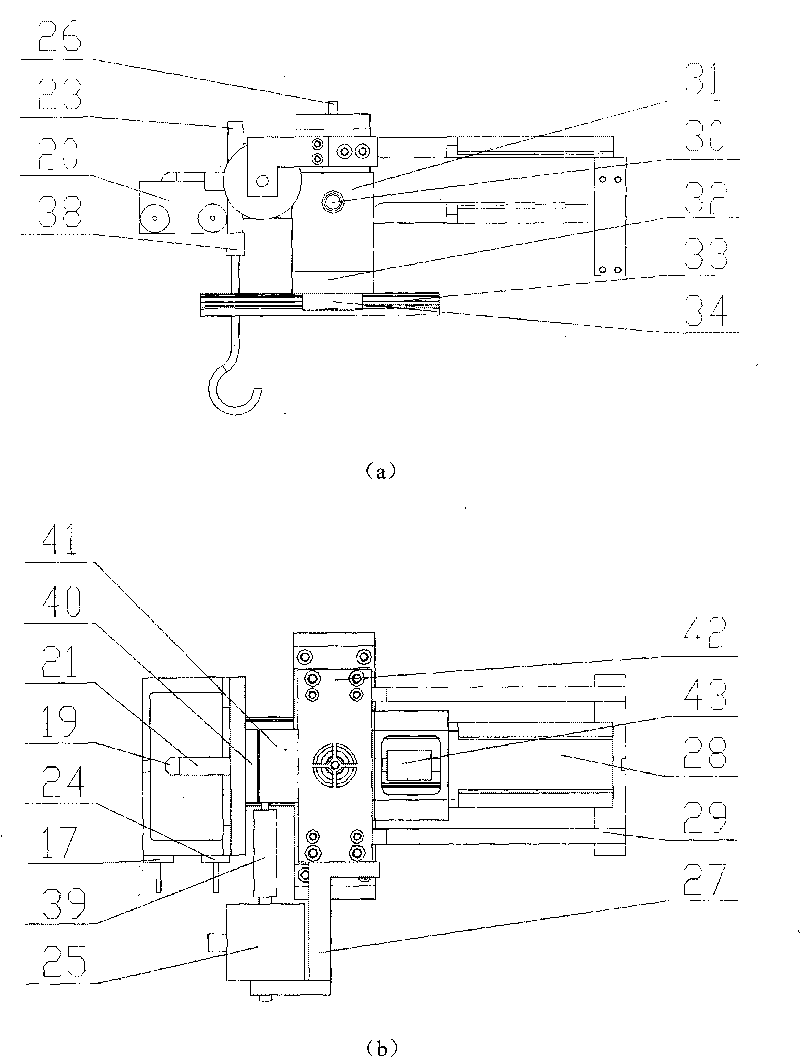

[0019] The structural principle and working principle of the present invention will be further described in detail below with reference to the accompanying drawings.

[0020] see figure 1 , a lubricant film thickness measuring instrument, including a support system, the support system includes a base plate 6, a support foot 1 and a support frame 2; the spindle system, the balance system, the loading system and the measurement system are all fixed with screws on the base plate 6 in the support system On; the spindle system, the balance system, the loading system and the measuring system are independent of each other when they are not working; when they are working, the balance ball 13 in the balance system and the loading ball 19 in the loading system are in contact with the spindle system. The discs 14 are in contact with a certain pressure.

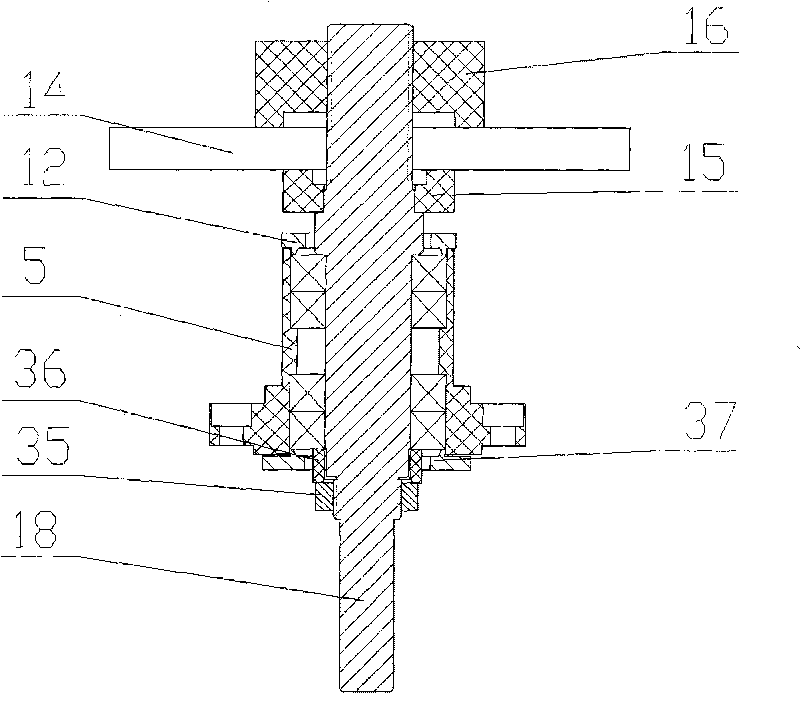

[0021] see figure 2 , figure 2 It is a schematic diagram of the structure of the main shaft system. The upper pressure block 16 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com