Method for preparing nitrogen-producing carbon molecular sieve

A manufacturing method and molecular sieve technology, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as unsatisfactory compressive strength performance, imperfect combination of process parameters, etc., achieve low cost, long service life, and increase production The effect of nitrogen rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

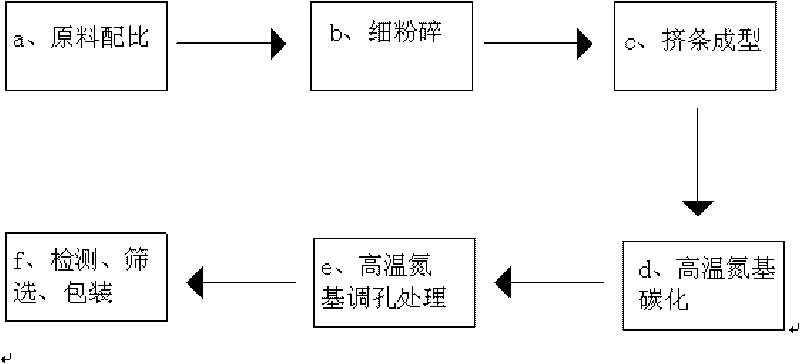

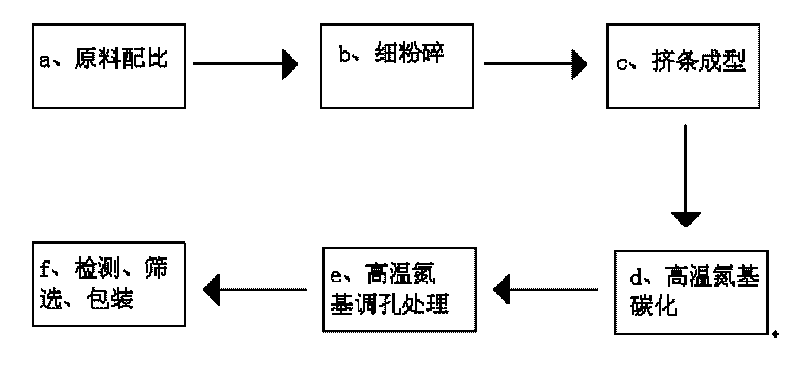

[0022] Example. The manufacture method of nitrogen carbon molecular sieve comprises following production steps:

[0023] a. Raw material ratio: fully mix 50 parts of flower mud, 20 parts of coal, and 5 parts of phenolic resin to obtain product A;

[0024] b. Finely pulverize, place the blocky product A in a pulverizer to fully pulverize it, and then place it in a ball mill to grind it to 2 microns to obtain product B;

[0025] c. Extrusion molding, with 50 parts of product B, 20 parts of tar, 2 parts of pitch and 0.1 part of Fe 2 o 3 , fully mixed and put into a kneader, after being kneaded by the kneader, it is formed into a granular material, that is, the so-called extrusion molding. After 20 minutes of kneading, the extrusion is formed into granules, and the diameter of the extruded particles is 1.5 mm. C product;

[0026] d. High-temperature nitrogen-based carbonization, place product C in the furnace, heat it while feeding nitrogen gas, and raise the temperature to 75...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com