Fe molecular sieve composite catalyst and preparation method thereof

A composite catalyst and molecular sieve technology, applied in molecular sieve catalysts, catalyst activation/preparation, separation methods, etc., can solve the problems of catalyst carbon deposition and deactivation, achieve good catalyst activity, improve anti-carbon deposition performance, and inhibit adsorption and deposition. effect of carbon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

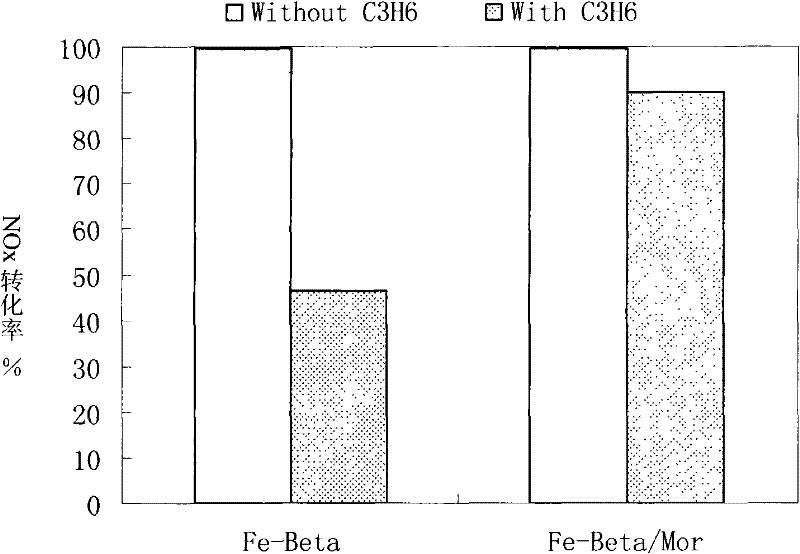

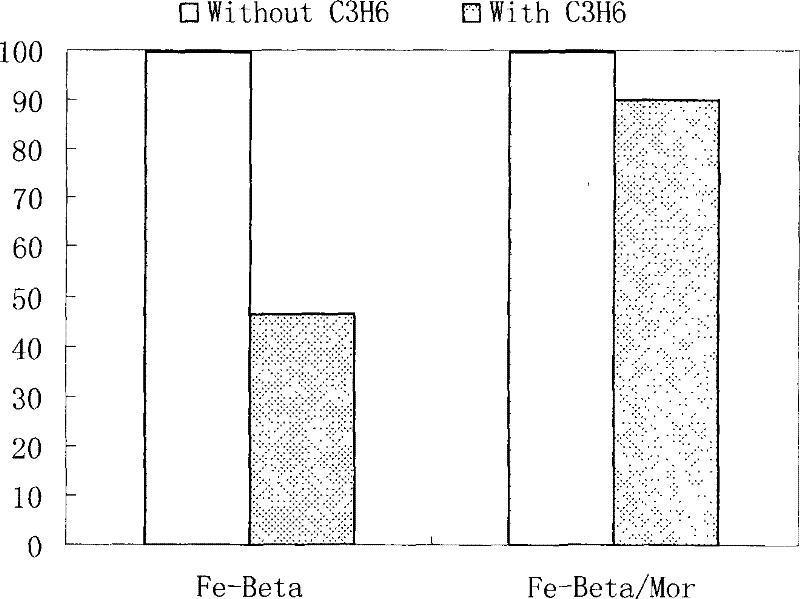

Image

Examples

Embodiment 1

[0023] A kind of Fe molecular sieve composite catalyst, comprises following component:

[0024] The content of the active component Fe is 2.5wt.%, the content of the catalyst carrier Beta is 82.5wt.%, and the mordenite is 15wt.%.

[0025] A preparation method of Fe molecular sieve composite catalyst, comprising the steps of:

[0026] 1. Measure 300mL of deionized water, add 5g of H-Beta molecular sieve with a Si / Al molar ratio of 12.5, stir on a magnetic stirrer for 30min at room temperature at 30°C, and then add 5g of FeCl according to the stoichiometric ratio 2 , stirred at room temperature for 24 hours, and carried out ion exchange;

[0027] 2. Wash and filter with 5 times deionized water to remove Cl ions in the solution, and dry the obtained filter cake in an oven at 110°C for 15 hours;

[0028] 3. Roast the dried filter cake in a muffle furnace at 600°C for 5 hours to obtain Fe / Beta molecular sieve catalysts, which are respectively recorded as Fe / ZSM-5, Fe / Beta, Fe / ZSM...

Embodiment 2

[0033] An Fe molecular sieve composite catalyst comprises the following components: the active component Fe is 3wt.%, the catalyst carrier Beta is 77wt.%, and the mordenite is 20wt.%.

[0034] A preparation method of Fe molecular sieve composite catalyst, comprising the steps of:

[0035] 1. Measure 350mL of deionized water, add 8g of H-Beta molecular sieve with a Si / Al molar ratio of 15, stir on a magnetic stirrer for 40min at room temperature of 30°C, and then add 4g of FeCl according to the stoichiometric ratio 2 , stirred at room temperature for 28 hours, and carried out ion exchange;

[0036] 2. Wash and filter with 6 times deionized water to remove Cl ions in the solution, and dry the obtained filter cake in an oven at 110°C for 15 hours;

[0037] 3. Calcining the dried filter cake in a muffle furnace at 600°C for 3 hours to obtain a Fe / Beta molecular sieve catalyst;

[0038] 4. Put the Fe / Beta molecular sieve catalyst obtained above into 80mL of water, add 2.5g of pre...

Embodiment 3

[0042] A kind of Fe molecular sieve composite catalyst, comprises following component:

[0043] The active component Fe is 5wt.%, the catalyst carrier Beta is 70wt.%, and the mordenite is 25wt.%.

[0044] A preparation method of Fe molecular sieve composite catalyst, comprising the steps of:

[0045] 1. Measure 250mL of deionized water, add 10g of H-Beta molecular sieve with a Si / Al molar ratio of 15, stir on a magnetic stirrer for 35min at room temperature of 30°C, and then add 2g of FeCl according to the stoichiometric ratio 2 , stirred at room temperature for 30 hours, and carried out ion exchange;

[0046] Second, wash and filter with 5 times deionized water to remove Cl ions in the solution, and dry the obtained filter cake in an oven at 110°C for 18 hours;

[0047] 3. Calcining the dried filter cake in a muffle furnace at 600°C for 4 hours to obtain a Fe / Beta molecular sieve catalyst;

[0048] 4. Put the Fe / Beta molecular sieve catalyst obtained above into 100mL of wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com