Microsphere separation method and screening system

A separation method and microsphere technology, applied in solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of no space for improving accuracy, speeding up separation speed, low sieve accuracy, etc., to ensure screening accuracy, reduce Work intensity, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The principle, system structure and separation implementation steps of the microsphere separation method and screening system provided by the present invention will be further described below in conjunction with the illustrations.

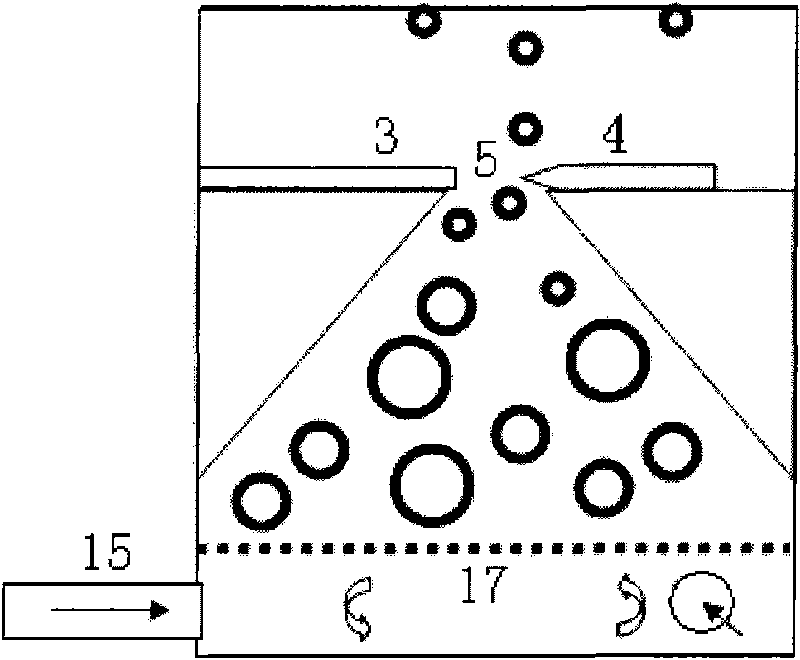

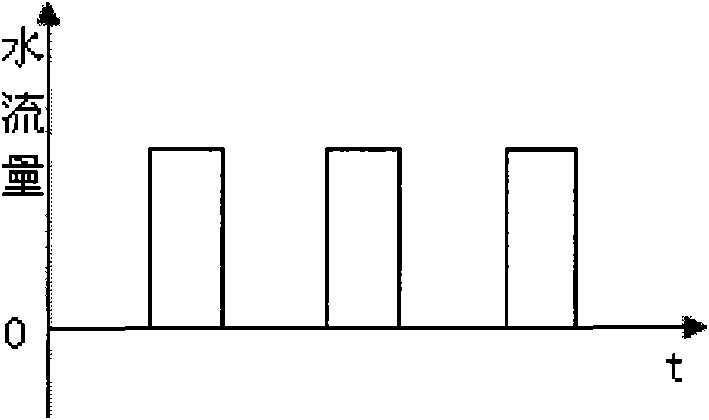

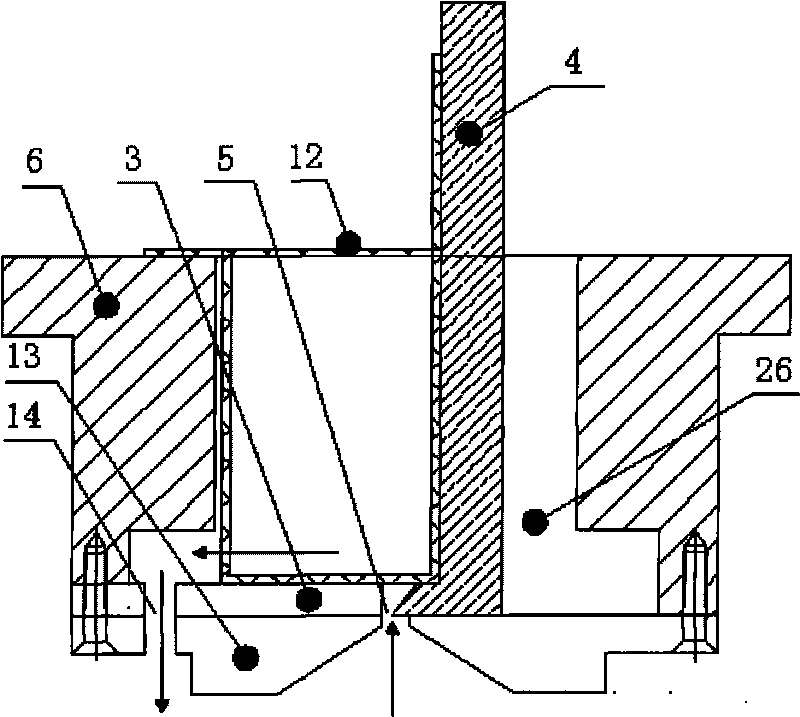

[0028] The microsphere separation method adopts the principle of narrow slit screening of microspheres (such as figure 1 As shown), the method adopts the static piece 3 and the moving piece 4 to form a narrow slit 5, sprays pulsed water flow at the bottom of the narrow slit 5, and drives the microspheres to disperse and pass through the narrow slit under the action of the periodic start-stop disturbance of the water flow to prevent the microspheres from The balls block the slit, and the screening of microspheres with different diameters can be realized by adjusting the width of the slit. That is, by adopting static sheet 3 and adjustable moving sheet 4 to form slit 5 to screen a large amount of microspheres placed on the separation net 17, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com