Color development enhancing method for glass

A glass and color rendering technology, applied in the field of color rendering enhancement technology, can solve the problems of low production efficiency, unsuitable for industrial scale production, poor coloring uniformity, etc., and achieves high production efficiency, improved glass strength and thermal stability, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

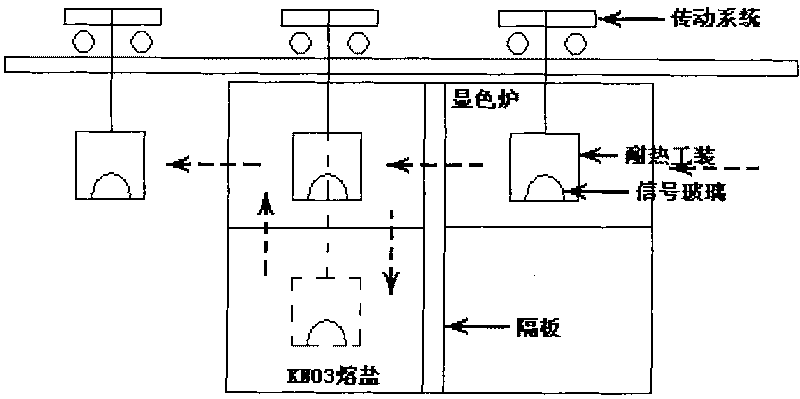

Method used

Image

Examples

Embodiment 1

[0033] 1) The composition ratio (wt%) is SiO 2 : 68%; Al 2 o 3 : 3%; B 2 o 3 : 10%; Na 2 O: 5%; K 2 O: 4%; ZnO: 10%; CdS: 1.2%; Se: 0.5%. Mix evenly, place in a corundum crucible, melt at 1400-1550°C, press at 1300°C to form several glass lamps with a weight of 100 grams, the size is Φ80×50mm, and the wall thickness is 3mm. Grind the bayonet of the annealed glass lamps for color enhancement treatment.

[0034] 2) Using 100wt% KNO 3 As a molten salt, it is melted in an electric furnace and clarified for more than 24 hours for later use.

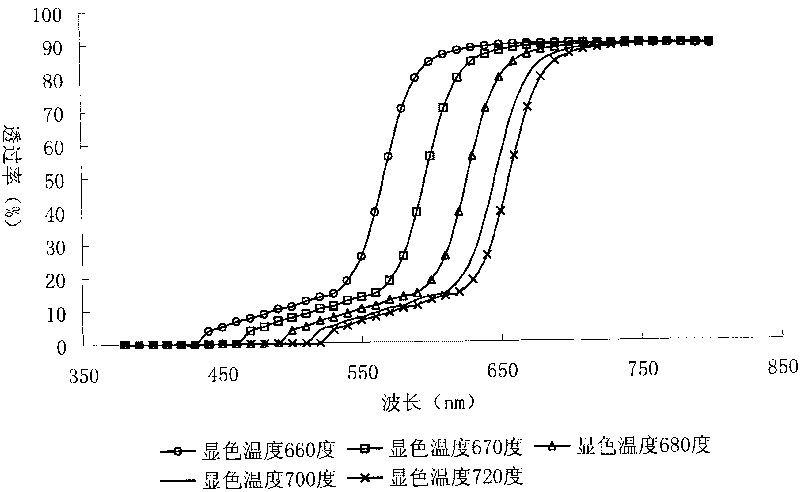

[0035] 3) Put the glass lamp made in step 1) into the heat-resistant tooling, hang the tooling in an electric furnace at a temperature of 660°C for color development, and the color development time is 20 minutes. Then, remove the tooling from the electric furnace and quickly put it into 100wt% KNO 3 In the molten salt, the temperature of the molten salt is 380° C., and the time is 5 minutes.

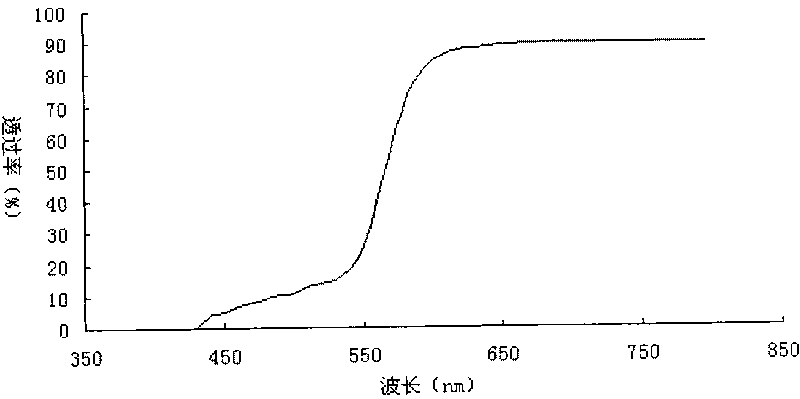

[0036] 4) Take out the glass lamp from ...

Embodiment 2

[0045] The same steps as in Example 1 were adopted. The difference is that in step 3), the glass lamps are put into the heat-resistant tooling, and the color development process is carried out in an electric furnace at a temperature of 670° C., and the color development time is 20 minutes.

[0046] The product of Example 2 is detected according to the detection method of the embodiment, and the data are listed in Table 2.

Embodiment 3

[0048] The same steps as in Example 1 were adopted. The difference is that in step 3), the glass lamps are put into the heat-resistant tooling to carry out the color development treatment in an electric furnace at a temperature of 680° C., and the color development time is 20 minutes.

[0049] The product of Example 3 is detected according to the detection method of the embodiment, and the data are listed in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com