Method for producing agricultural potassium metaphosphate

A technology of potassium metaphosphate and its production method, which is applied in phosphate fertilizer, application, agriculture, etc., can solve the problems of no patent application, etc., and achieve the effects of no waste discharge, easy treatment, good economic benefits and environmental protection benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

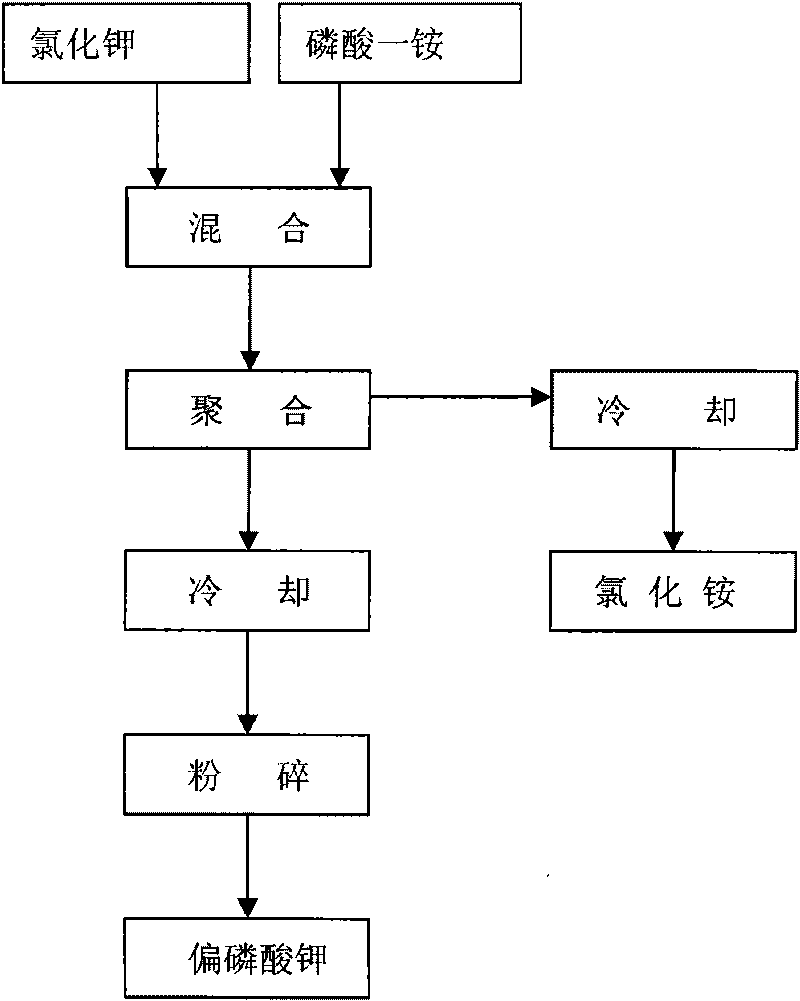

Method used

Image

Examples

Embodiment 1

[0030] With N 11.3%, P 2 o 5 45.1% Monoammonium Phosphate and K 2 O 60.6% Potassium Chloride as raw material, mix 120kg powdered monoammonium phosphate and 57kg Potassium Chloride, place in a graphite crucible, heat to 650-750°C and keep it for 2 hours, pour out the melt and cool to room temperature, Crush to ≤1mm to get 113kg potassium metaphosphate product. Pump the gas escaping from the graphite crucible to the settling chamber and cool it to 110°C-180°C to obtain 48kg of ammonium chloride, and the rest of the waste gas is washed with water and then emptied. The product quality is as follows:

[0031] Potassium metaphosphate composition: P 2 o 5 46.8%;K 2 O 30.3%

[0032] Ammonium chloride composition: N 25.3%.

Embodiment 2

[0034] The raw materials used are the same as in Example 1. Mix 120kg of powdered monoammonium phosphate and 65kg of potassium chloride, place in a graphite crucible, heat to 750-800°C and keep it for 1 hour, then pour out the melt, cool it to room temperature, and crush it to 1mm to get 111kg of potassium metaphosphate products. Pump the gas escaping from the graphite crucible to the settling chamber and cool it to 110°C to 180°C to obtain 47.2kg of ammonium chloride, and the rest of the waste gas is washed with water and then emptied. The product quality is as follows:

[0035] Potassium metaphosphate composition: P 2 o 5 47.6%, K 2 O 33.2%;

[0036] Ammonium chloride composition: N 25.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com