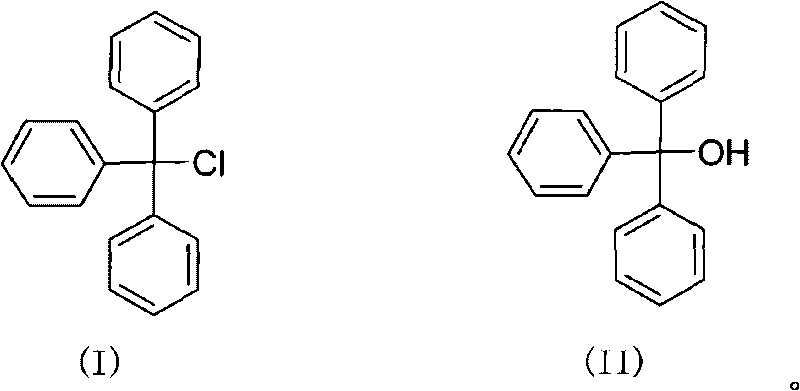

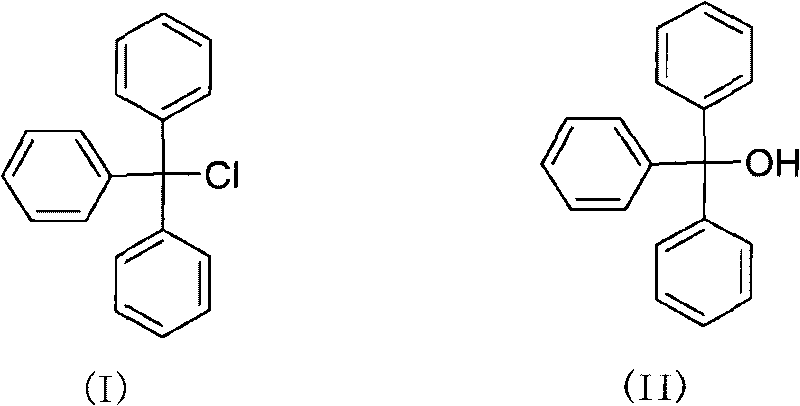

Green synthesizing method of triphenylchloromethane

A technique for the synthesis of triphenylchloromethane, which is applied in chemical instruments and methods, organic chemistry, preparation of halogenated hydrocarbons, etc., can solve problems such as unfavorable large-scale production, difficulties in use and transportation, and difficult control, and achieve production costs Low, less waste, environment-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] In a 1000ml four-necked flask equipped with a thermometer and mechanical stirring, add 130g (0.5mol) of triphenylmethanol and 50g of bis(trichloromethyl)carbonate, dissolve and stir with 200ml of toluene, and then add 1.5 g of triethylamine. g, heated to 80°C. The reaction temperature was maintained and stirred for 2 hours. After the reaction was completed, toluene was recovered by distillation under reduced pressure, and the crude product was recrystallized from petroleum ether to obtain 136.5 g of white pure product with a yield of 98% and a melting point of 109-111°C.

Embodiment 2

[0020] In a 1000ml four-neck flask equipped with a thermometer and mechanical stirring, add 130g (0.5mol) of triphenylmethanol and 80g of bis(trichloromethyl)carbonate, dissolve and stir with 200ml of dichloromethane, and then add 1.5 mol of pyridine. g, heated to 40°C. The reaction temperature was maintained and stirred for 5 hours. After the reaction was completed, dichloromethane was recovered by distillation under reduced pressure, and the crude product was recrystallized from petroleum ether to obtain 124 g of white pure product with a yield of 89% and a melting point of 109-112°C.

Embodiment 3

[0022] In a 1000ml four-necked flask equipped with a thermometer and a mechanical stirrer, add 130g (0.5mol) of triphenylmethanol and 80g of bis(trichloromethyl) carbonate, and use 200ml of toluene / chlorobenzene (V / V=1: 1) The mixed solvent is dissolved and stirred, and heated to 80°C. The reaction temperature was maintained and stirred for 2 hours. After the reaction was completed, the solvent was recovered by distillation under reduced pressure, and the crude product was recrystallized from petroleum ether to obtain 129 g of pure product with a yield of 93% and a melting point of 109-112°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com