A kind of waste plastics, montmorillonite and waste rubber composite material and preparation method thereof

A technology of waste plastics and composite materials, which is applied in the field of waste plastics, montmorillonite and waste rubber composite materials and their preparation, to achieve the effects of protecting the environment, reducing weight, and improving strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

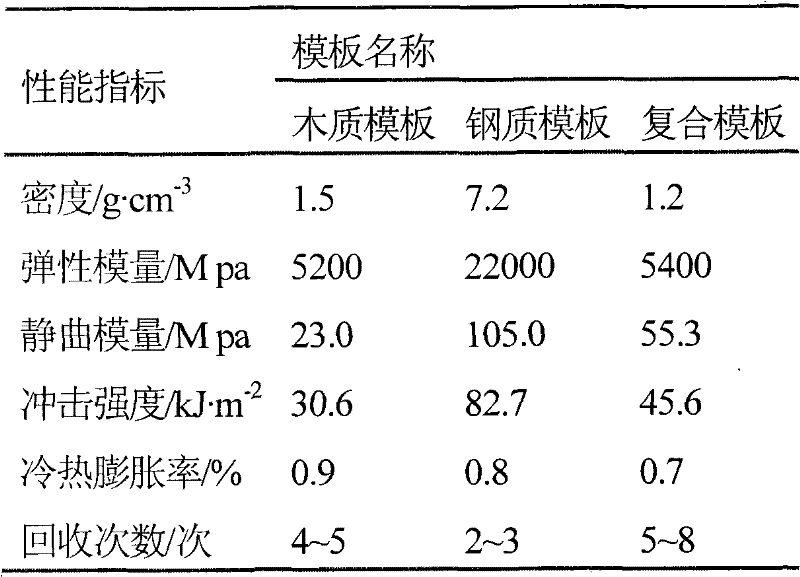

Embodiment 1

[0022] A kind of waste plastics, montmorillonite and waste rubber composite material, its composition comprises: waste plastics, montmorillonite, waste rubber, auxiliary agent, and the weight of described waste plastics is 70 grams, wherein contains waste and old polyethylene plastics 35 grams 14 grams of waste and old polypropylene plastics, 7 grams of waste and old polystyrene plastics and 14 grams of waste and old polyvinyl chloride plastics, 20 grams of montmorillonite, 5 grams of waste rubber powder, described auxiliary agents include 0.1 gram of stearic acid, 2 grams of paraffin wax gram, antioxidant tetrakis (beta-(3,5-di-tert-butyl-4-hydroxyphenyl) pentaerythritol fat parts by weight is 0.05 gram, and its preparation process is to get 70 grams of waste plastics to clean, dry, screen, pulverize , granulation; the cation exchange total capacity is 50~100meg / 100g, particle diameter is 20 grams of montmorillonite of 40~60 μ m, under the presence of 800ml of water, high-spee...

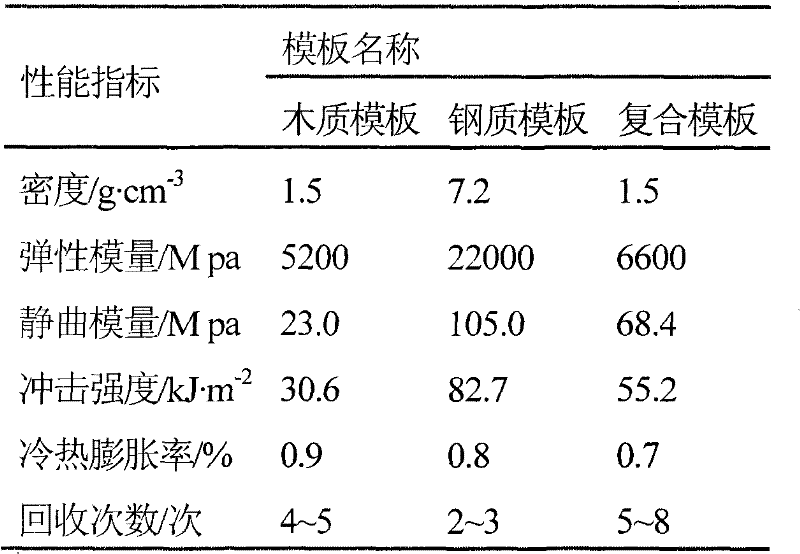

Embodiment 2

[0027] A composite material of waste plastics, montmorillonite and waste rubber, comprising: waste plastics, montmorillonite, waste rubber, additives, the weight of the waste plastics is 100 grams, which contains 20 grams of waste polyethylene plastics , 60 grams of waste and old polypropylene plastics, 10 grams of waste and old polystyrene plastics and 10 grams of waste and old polyvinyl chloride plastics, 40 grams of montmorillonite, 10 grams of waste rubber powder, described auxiliary agents include 0.5 grams of stearic acid, 3 grams of paraffin wax gram, antioxidant tetrakis (beta-(3,5-di-tert-butyl-4-hydroxyl phenyl) pentaerythritol fat parts by weight is 0.1 gram, and its preparation technology is to get the waste plastics that parts by weight are 100 grams to clean, Drying, screening, crushing, and granulation; 40 grams of montmorillonite with a total capacity of cation exchange of 60-80meg / 100g and a particle size of 100-150μm is stirred at high speed in the presence of...

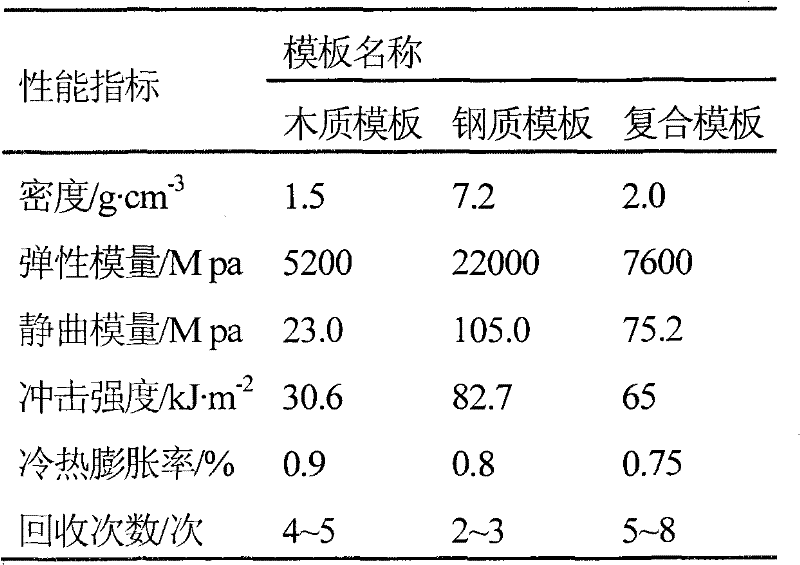

Embodiment 3

[0032] A kind of waste plastics, montmorillonite and waste rubber composite material, its composition comprises: waste plastics, montmorillonite, waste rubber, auxiliary agent, and the weight of described waste plastics is 120 grams, wherein contains waste and old polyethylene plastics 36 grams , 36 grams of waste and old polypropylene plastics, 48 grams of waste and old polystyrene plastics, 50 grams of montmorillonite, 15 grams of waste rubber powder, described auxiliary agents include 1 gram of stearic acid, 5 grams of paraffin, antioxidant four (β- (3,5-di-tert-butyl-4-hydroxyphenyl) pentaerythritol fat parts by weight is 1 gram, and its preparation process is to take the waste plastics that parts by weight are 120 grams to clean, dry, screen, pulverize, granulate ; 50 grams of montmorillonite with a total capacity of cation exchange of 150 to 200 meg / 100 g and a particle size of 80 to 100 μm were stirred at high speed in the presence of 500 ml of ethanol to form a stable...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com