Method for improving stability of liquid aminopeptidase and application of aminopeptidase

An aminopeptidase and stability technology, applied in microorganism-based methods, biochemical equipment and methods, enzymes, etc., can solve problems such as limiting the application of protein hydrolyzates, and achieve the effect of easy expansion of production and good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

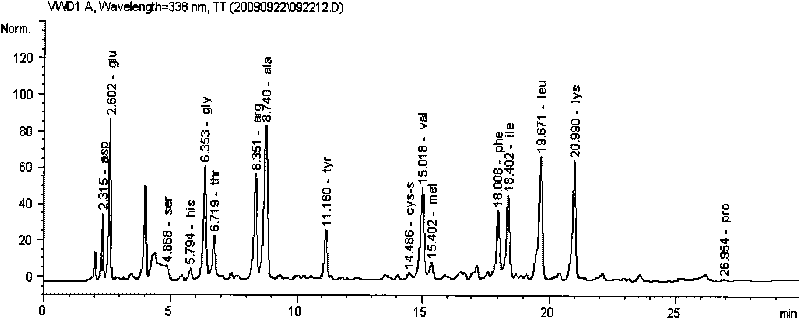

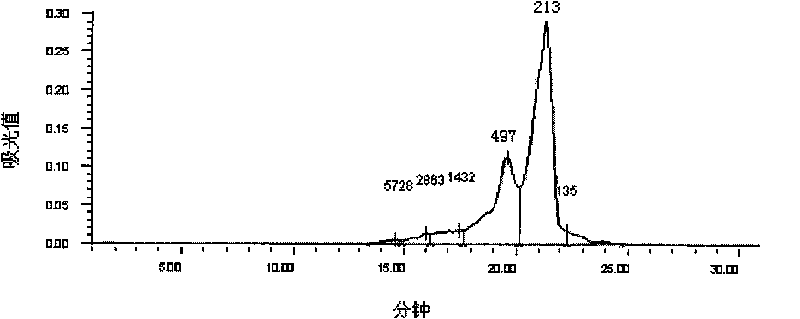

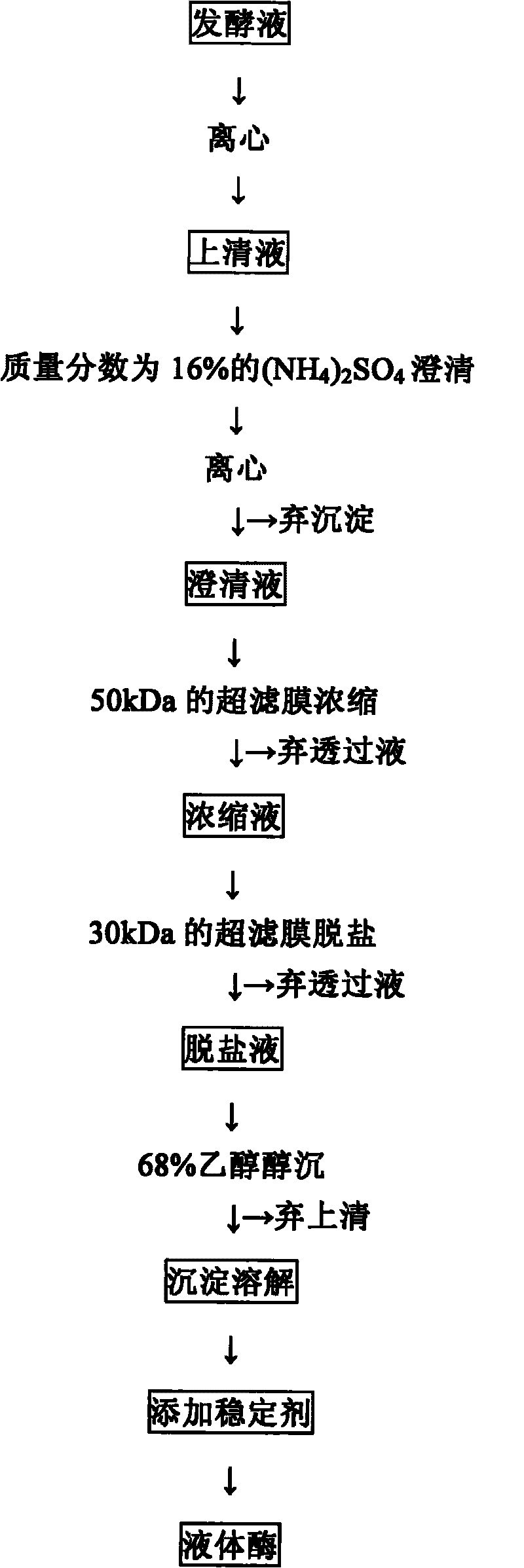

[0044] Centrifuge the Bacillus subtilis Zj016 fermentation broth at 4°C for 10 min at 10,000 rpm to collect 3.5L of the fermentation broth, add (NH 4 ) 2 SO 4670g (stirring while adding), 4°C, 10000rpm centrifuge for 10min to collect 3.6L of clarified liquid, select 50kDa ultrafiltration membrane to concentrate to 1.4L, flow rate 30-35mL / min; select 30kDa ultrafiltration membrane to desalinate 1.4L, The flow rate is 40mL / min; add 3.3L of pre-cooled absolute ethanol to the desalination solution, after 10min, centrifuge at 4°C and 8000rpm for 10min to collect the precipitate, dissolve the precipitate, add sodium benzoate as a stabilizer, and control the quality of sodium benzoate in the enzyme solution The concentration is 0.1%, and the liquid aminopeptidase is obtained. Soybean protein isolate is mixed with a 6% solution, placed in a constant temperature water bath at 85°C for 15 minutes, cooled to adjust the pH to 8.5, and the amount of enzyme added E / S=3.25×10 5 U / g, the f...

Embodiment 2

[0046] Centrifuge the Bacillus subtilis Zj016 fermentation broth at 4°C for 10 min at 10,000 rpm to collect 2.5L of the fermentation broth, add (NH 4 ) 2 SO 4 470g (stirring while adding), 4°C, 10000rpm centrifuge for 10min to collect 2.5L of clarified liquid, select 50kDa ultrafiltration membrane to concentrate to 0.85L, flow rate 30-35mL / min; select 30kDa ultrafiltration membrane to desalt 0.85L, Flow rate 40mL / min, add pre-cooled absolute ethanol 1.8L to the desalination solution, after 10min, centrifuge at 4°C, 8000rpm for 10min to collect the precipitate, dissolve the precipitate, add 0.2μmol / L Co 2+ The cofactor is liquid aminopeptidase. Soybean protein isolate is mixed with a 6% solution, placed in a constant temperature water bath at 85°C for 15 minutes, cooled to adjust the pH to 8.5, and the amount of enzyme added E / S=2.5×10 5 U / g, the content of free amino acids in the protein hydrolyzate hydrolyzed at 50°C for 4h is 64.72mg / mL, macromolecules with a molecular we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com