Process method for reopening old furnace of cored line-frequency induction electric furnace for producing copper-nickel alloy

A technology of induction electric furnace and process method, which is applied to the improvement of process efficiency, furnace, crucible furnace, etc., which can solve the problems of not being able to stop and start immediately, less investment in equipment, and low power consumption, so as to prolong the absolute service life and reduce production. Cost, guarantee the effect of repeated use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

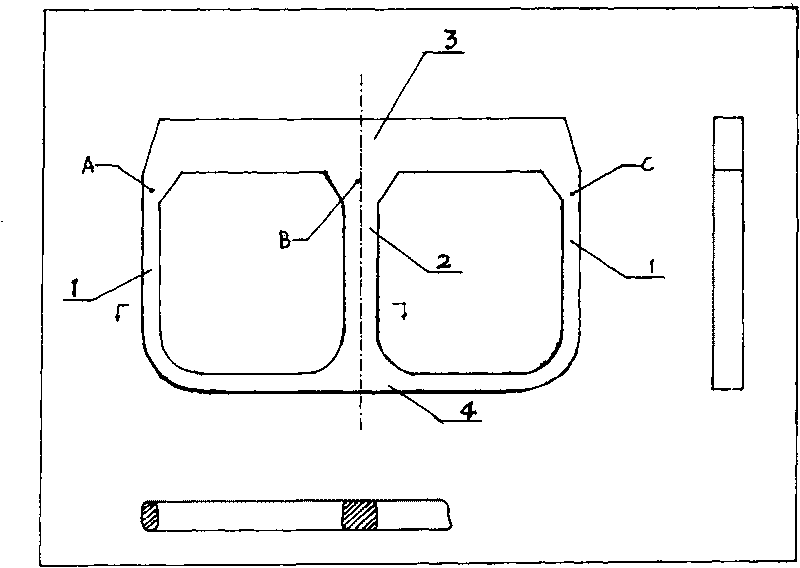

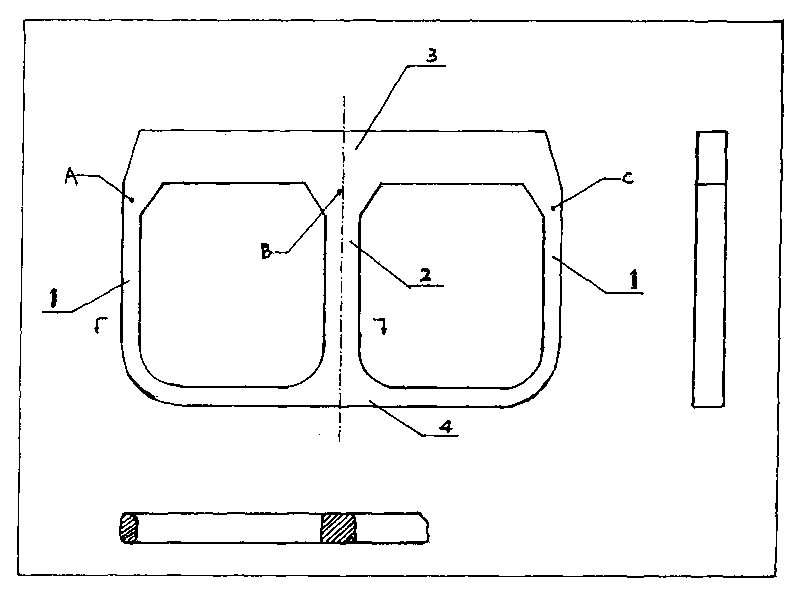

[0015] The present invention is further described in conjunction with the embodiment that accompanying drawing provides:

[0016] A process method for reopening an old furnace with a cored power frequency induction furnace for producing white copper, the specific operation steps are:

[0017] a. Before the shutdown of the white copper with a cored power frequency induction furnace, add electrolytic copper for alloying and smelting to dilute the impurity composition of the melting groove mold, so that the nickel content of the white copper melting groove mold will be reduced to less than 3% when the old furnace is reopened. At the same time, the composition of iron and manganese is reduced to less than 0.5%. By reducing the content of nickel, iron and manganese in the melting channel mold, the temperature of the melting channel mold is lowered to prepare for the next furnace start;

[0018] b. Check whether the main circuit, control circuit and cooling water system are normal b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com