Method for measuring and calculating all iron content in imported iron ore

A technology of iron content and calculation method, applied in the direction of measuring device, preparation of test samples, color/spectral characteristic measurement, etc., can solve problems affecting the speed of certificate issuance and unfavorable development of iron ore trade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

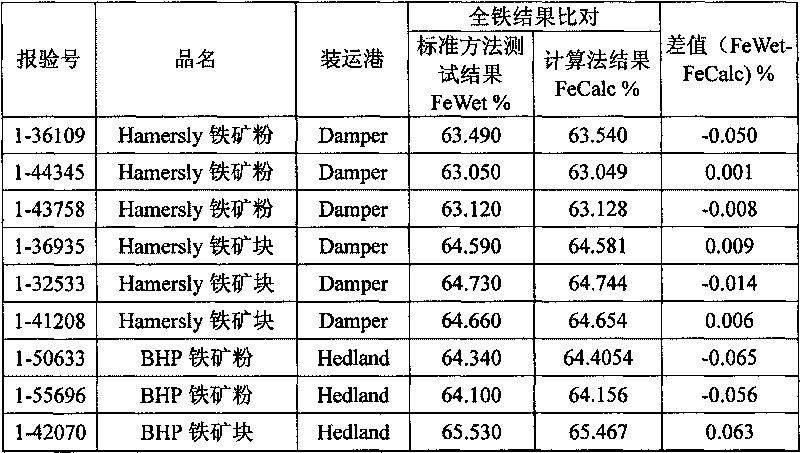

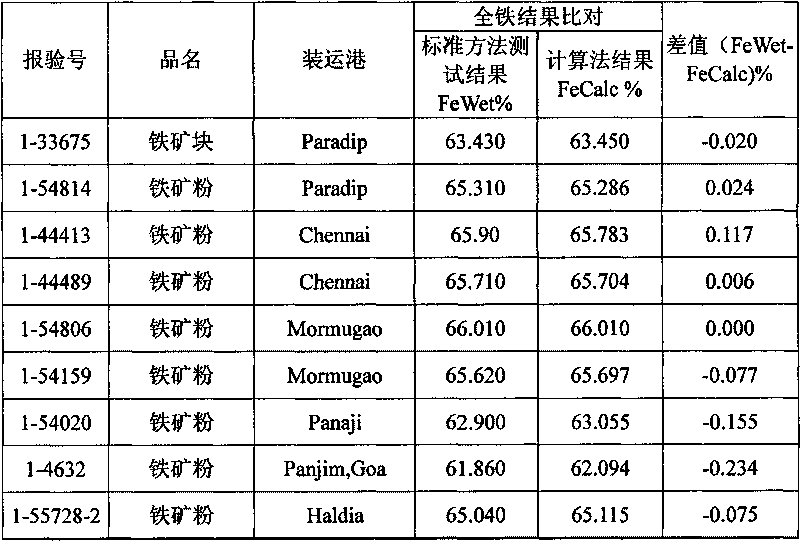

[0068] Example: For iron ore samples imported from Australia, India, Brazil and South Africa, the steps are as follows:

[0069] (1) According to the standard GB / T6730-86 "Methods for Chemical Analysis of Iron Ore", the samples are prepared for analysis, the samples are thoroughly mixed and dried at 105°C, and placed in a desiccator to cool to room temperature for later use.

[0070] (2) Weigh about 1.0g sample in a platinum dish, put it in a muffle furnace, slowly raise the temperature to 1000℃, burn to constant weight, take it out and put it in a desiccator to cool to room temperature, weigh it, Calculate the sample ignition loss LOI according to formula (6).

[0071] LOI=(m 1 +m 2 -m 3 )×100 / m 2 …………………………………(6)

[0072] Where: m 1 -The weight of the platinum dish

[0073] m 2 -The weight of the sample

[0074] m 3 -The weight of the sample and platinum dish after ignition

[0075] LOI-Ignition reduction.

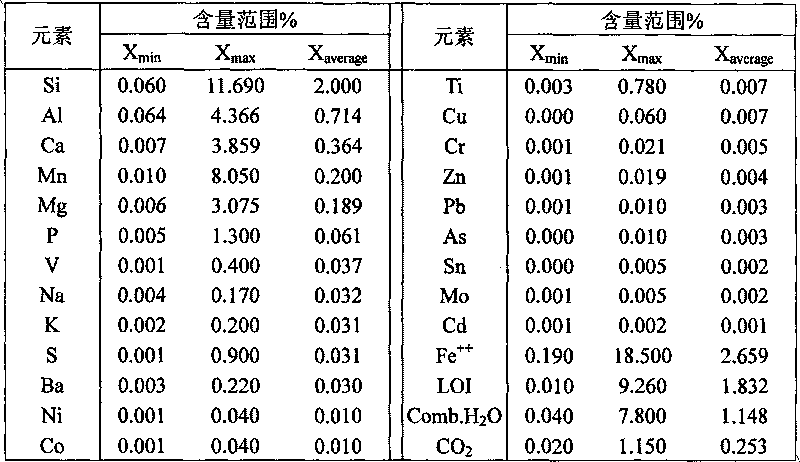

[0076] (3) According to the standard ISO9516-1 "Iron Ore-X-Ray Fluorescence Spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com