Gel battery for electric vehicle

A gel battery, electric vehicle technology, applied in electric vehicles, lead-acid batteries, battery pack components and other directions, can solve the problems of insufficient performance, high oxygen recombination efficiency, uneven distribution, etc., and achieve good mechanical strength and elasticity. , Improve the deep cycle life, the effect of easy injection of colloid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

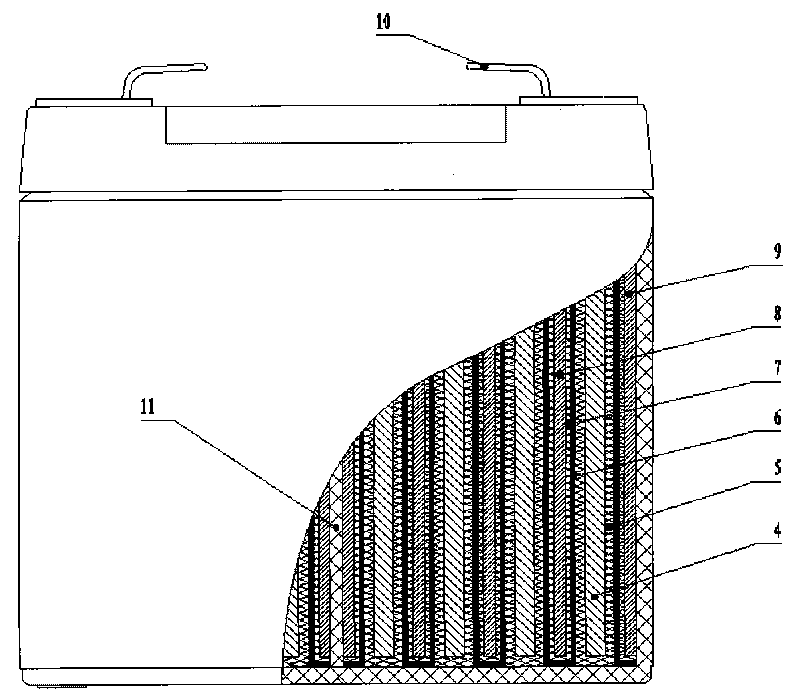

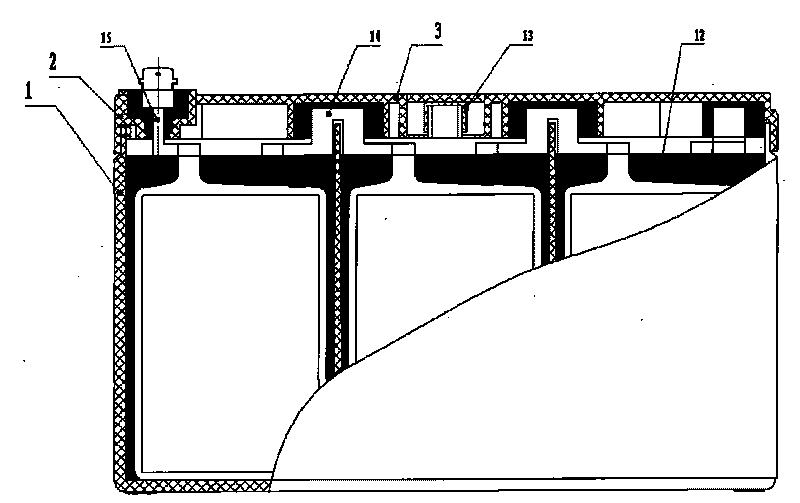

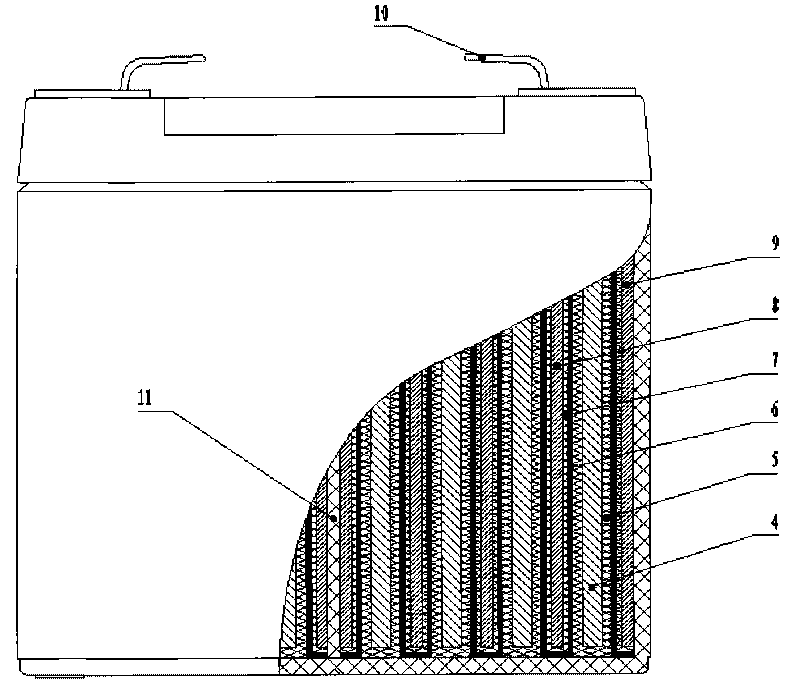

[0022] refer to figure 1 , 2 The gel battery for electric vehicles includes a battery tank 1, a battery middle cover 2 arranged at the opening of the battery tank 1, a battery upper cover sheet 3 sealed on the battery middle cover 2, a positive plate 4 and a negative electrode arranged in the battery tank 1 plate 8, the positive plate 4 is covered with a glass fiber mat separator 5 with a "U" structure, the negative plate 8 is covered with a composite glass fiber separator with a "U" structure, and the composite glass The fiber separator is composed of two glass fiber layers, the outer layer is ultra-fine glass fiber base paper 6, the inner layer is glass fiber mat 7, and the battery tank 1 is also equipped with a colloidal electrolyte with a colloid content of 4-10%. 12. The thickness of the glass fiber felt separator 5 is twice the thickness of the glass fiber felt 7 . The positive plate 4 is a paste-type positive plate, and the negative plate 8 is a paste-type negative p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com