Method for granulating powdery active lime, special equipment and midbody

A technology of active lime and granulation equipment, which is applied in the field of granulation of powdered active lime for ironmaking and special equipment for powdered active lime granulation, which can solve problems such as waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

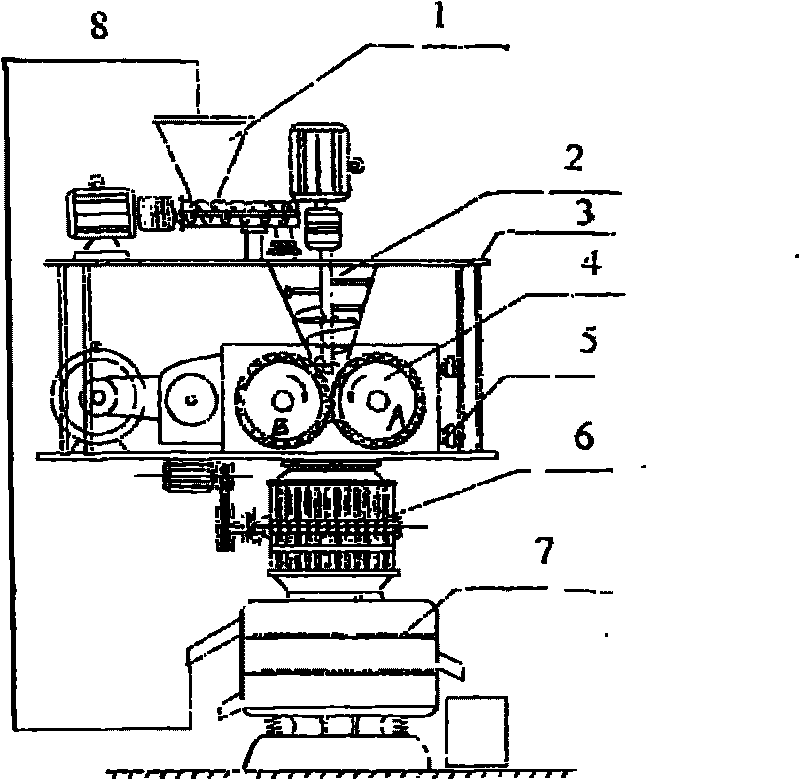

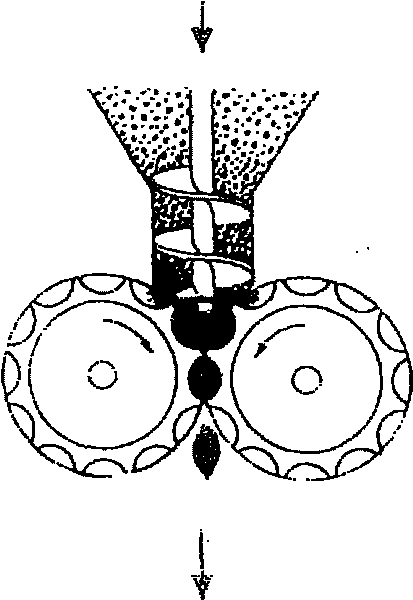

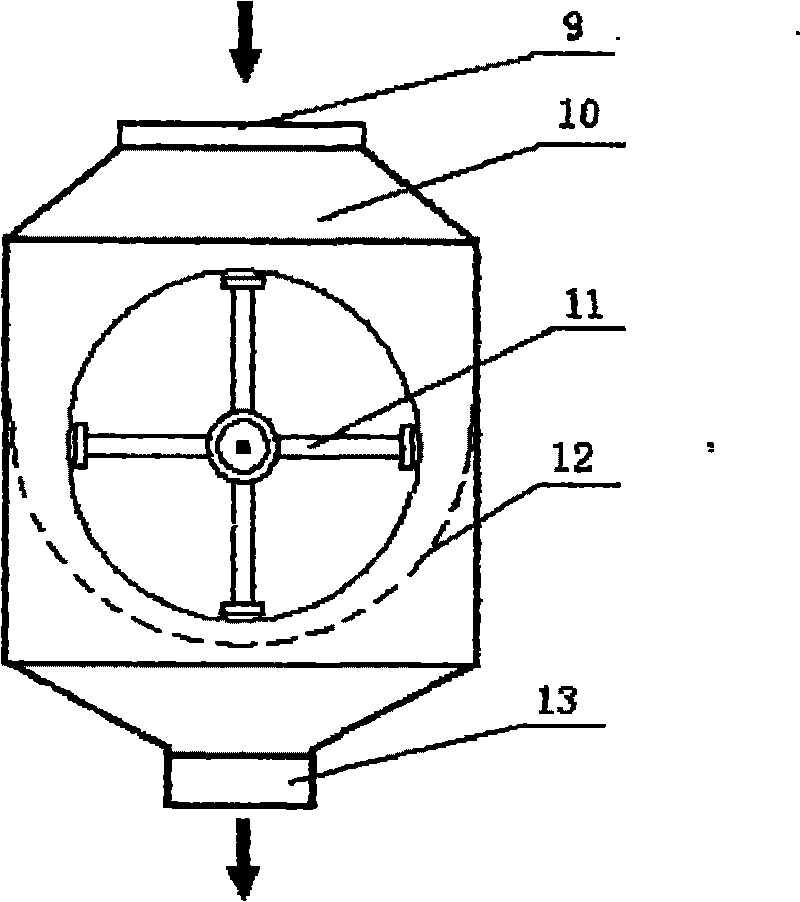

[0031] Example 1 The active lime with activity degree of 350ml-370ml and calcium oxide content of 95%-98% is added into the hopper with quantitative feeder 1, and powdered active lime is pressed into the flaking unit through forced feeder 2. The strip-shaped active lime is introduced into the crusher for crushing, and after screening, it becomes active lime pellets of different particle size grades required by users, which are 14 mesh, 18 mesh, 28 mesh, 35 mesh and other particle sizes. The detected activity is 350ml-370ml, and the calcium oxide content is 95%-98%.

Embodiment 2

[0032] Example 2 The active lime with an activity degree of 370ml-400ml and a calcium oxide content of 95%-98% is added to the hopper with a quantitative feeder 1, and the powdered active lime is pressed into the flaking unit through a forced feeder 2, The strip-shaped active lime is introduced into the crusher for crushing, and after screening, it becomes active lime pellets of different particle size grades required by users, which are 14 mesh, 18 mesh, 28 mesh, 35 mesh and other particle sizes. The detected activity is 370ml-400ml, and the calcium oxide content is 95%-98%.

Embodiment 3

[0033] Embodiment 3 is the same as above, the activated lime with activity degree of 400ml-450ml and calcium oxide content of 95%-98% is made into granular activated lime with 400ml-450ml and calcium oxide content of 95%-98%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com