High-strength welding wires of gas shielded welding needing thermal refining after welding

A technology of quenching and tempering treatment and gas protection, applied in welding medium, heat treatment furnace, heat treatment equipment and other directions, can solve the problem of not belonging to high-strength materials, etc., and achieve the effect of good mechanical properties, good hydrogen embrittlement resistance, and good low temperature toughness

Inactive Publication Date: 2010-06-09

BAOSHAN IRON & STEEL CO LTD

View PDF3 Cites 26 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This method requires quenching and tempering treatment after welding, but the tensile strength of the weld metal is only 500MPa, which is not a high-strength material, and it is a submerged arc welding wire, and its mechanical properties need to be matched with a specific flux

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

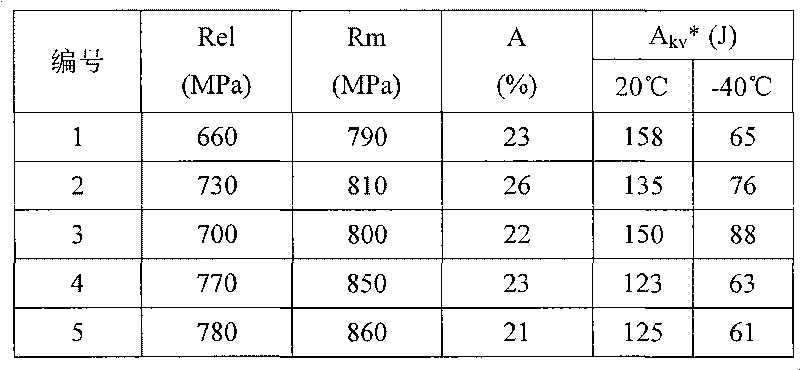

[0020] According to the chemical composition range of the welding wire of the present invention, it is smelted with a 300t converter and hot rolled into The wire rod is then subjected to rough drawing, intermediate annealing treatment, fine drawing process and copper plating process, and finally produces a The welding wire, the chemical composition of the welding wire is shown in Table 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Impact absorption energy | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to welding wires, in particular to high-strength welding wires needing hardening and tempering after welding, comprising the following chemical components by weight percent: 0.03-0.12 wt% of C, 0.30-0.80 wt% of Si, 1.2-2.2 wt% of Mn, 1.0-2.0 wt% of Ni, 0.05-0.30 wt% of Cu, 0.10-0.50 wt% of Cr, 0.20-0.80 wt% of Mo, 0.03-0.20 wt% of Ti, equal to or less than 0.015 wt% of S, less than or equal to 0.020 wt% of P, and the balance Fe and inevitable impurity elements. As for the welding wires after rich Ar gas shielded welding, under the thermal refining state, the mechanical property of the obtained welded metal is follows: yield strength ReL is equal to or greater than 630MPa, tensile strength Rm is equal to or greater than 780MPa, elongation A is equal to or greater than 20%, and absorbed energy Akv is equal to or greater than 60J under the temperature of -40 DEG C. The welded metal of the welding wires has high strength, good low-temperature toughness and favorable welding technological property after hardening and tempering.

Description

technical field [0001] The invention relates to a welding wire, especially a high-strength welding wire which needs to be quenched and tempered after welding. Background technique [0002] At present, high-strength steel plates with yield strength above 700MPa and some high-strength castings and forgings have been widely used in construction machinery, mining machinery, port and wharf machinery and other fields. The welding production of this kind of high-strength steel can usually be divided into two types of situations. One kind of situation is that the steel grades are quenched and tempered first, and then welded, that is, heat treatment is no longer required after welding; the other kind of situations is that the steel grades are first processed Welding, and then the overall quenching and tempering treatment. The existing high-strength steel welding materials and their welding methods that require heat treatment after welding are as follows: [0003] Chinese patent CN1...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23K35/30C21D9/50

Inventor 屈朝霞王海涛

Owner BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com