MEMS wafer level vacuum packaging process

A vacuum packaging, wafer-level technology, applied in decorative arts, microstructure devices, manufacturing microstructure devices, etc., can solve the problems of large influence on bonding strength, uneven glass surface, large packaging stress, etc., and achieve airtightness Good, high strength and toughness, simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027]A MEMS wafer-level vacuum packaging method, comprising the following steps:

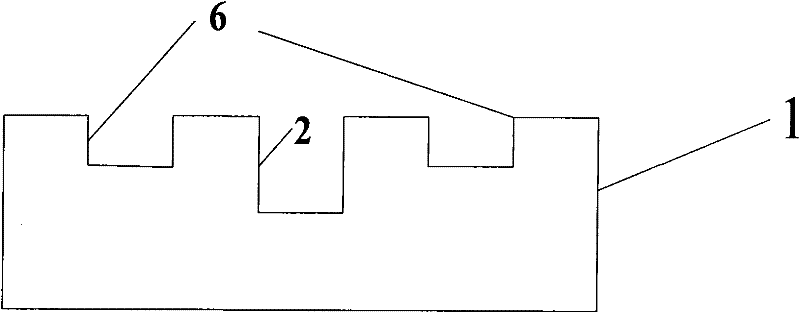

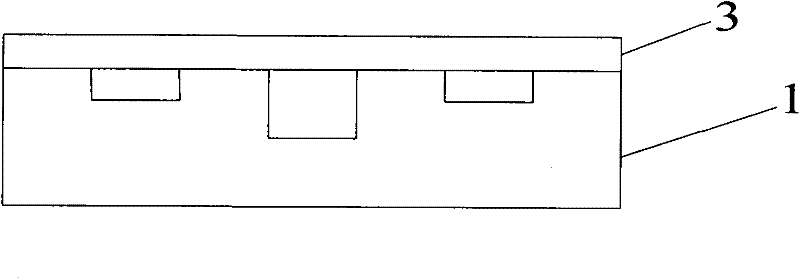

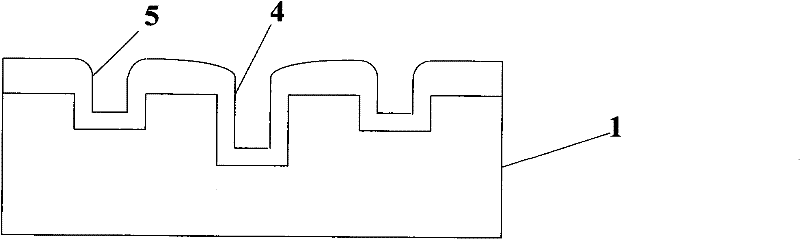

[0028] In the first step, the packaging groove and the annular buffer groove surrounding the packaging groove are etched on the Si wafer (such as a 4-inch wafer) by using Si micromachining technology. First, the packaging groove is etched, and then the buffer groove area is photoetched. The on-chip etched buffer trenches are shallower than the package trenches. When photoetching shallow grooves, the protection of deep packaging grooves can be protected by dry film photoresist, and the micromachining process of the pattern structure on the Si original sheet is a wet etching process or a dry inductively coupled plasma (ICP) etching process. Etching process, reactive ion etching or deep reactive ion etching. The aspect ratio of the packaging groove is determined according to the packaging requirements of the device. It can be less than 1:1 or greater than 1:1. The depth of the ring buffer groove c...

Embodiment 2

[0036] A MEMS wafer-level vacuum packaging method, comprising the following steps:

[0037] In the first step, the packaging groove and the annular buffer groove surrounding the packaging groove are etched on the Si wafer (such as a 4-inch wafer) by using Si micromachining technology. First, the packaging groove is etched, and then the buffer groove area is photoetched. The on-chip etched buffer trenches are shallower than the package trenches. When photoetching shallow grooves, the protection of deep packaging grooves can be protected by dry film photoresist (such as the dry film photoresist series produced by DuPont, USA), and the micromachining process on the Si wafer is dry inductive coupling. Plasma (ICP) etching process, the aspect ratio of the packaging groove is determined according to the packaging requirements of the device, for example, the depth is 300 microns, the width is 400 microns, the depth of the ring buffer groove is smaller than the depth of the packaging ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com