Novel energy-saving ceramic tile

A ceramic tile and a new type of technology, applied in the field of building decoration materials, can solve the problems of increased production cost of ceramic enterprises, high firing temperature, and inability to shorten the firing cycle, so as to achieve broad market economic benefits, shorten the firing cycle, and enhance the The effect of enterprise competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

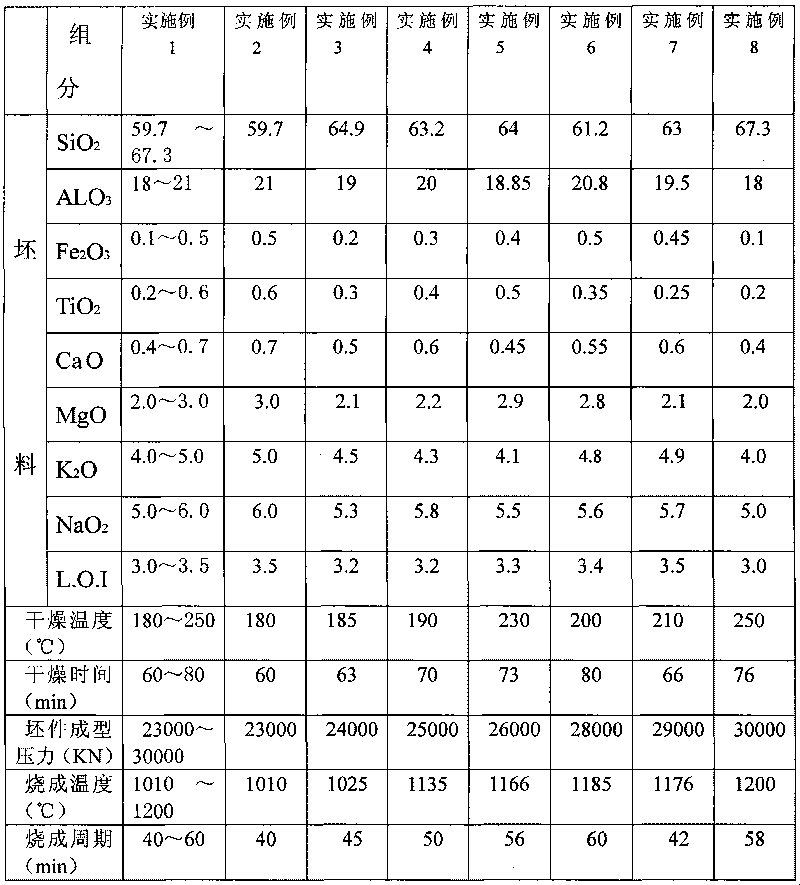

[0027] Below in conjunction with specific embodiment the present invention is described in further detail:

[0028] The present invention is mainly by improving the chemical composition MgO in the ceramic raw material production formula; K 2 O; Na 2 The percentage content of O is realized.

[0029]

[0030] The above-mentioned examples are made into finished products according to the following process flow: raw material batching → ball milling → color matching paste → sieving and iron removal → spray drying → silo aging → granulation → press forming → dryer drying → kiln firing → polishing line Polishing→finished product grading→packaging→warehousing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com