Halogen-free flame-retardant and low-odor polypropylene/layered double-hydroxide nanocomposite and preparation method thereof

A nanocomposite material and hydroxide technology, applied in the field of polypropylene/layered double hydroxide nanocomposite material and its preparation, can solve the research on flame retardancy of layered double hydroxide, dispersion inhomogeneous compatibility and other problems to achieve the effect of improving physical and chemical comprehensive properties, reducing odor and improving flame retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Step 1. Preparation of Nano Halogen Free Flame Retardant System

[0021] Zn(NO 3 ) 2 ·6H 2 O and Al(NO 3 ) 3 9H 2 O molar ratio n=3, metal ion total concentration is in the aqueous solution of the mixed salt of 0.4mol / L, add Al(NO 3 ) 3 9H 2 O total molar weight 1.2 times of 3-hydroxyphenyl phospho-propionic acid CEPPA, drip the mixed solution that weight concentration is 20%NaOH, to pH value is 9, in N 2 Under protection, stirred for 2h, aged at 60°C for 24h, then cooled, filtered, washed, and dried to obtain nano-CEPPA-intercalated Zn 3 Al / NO 3 -LDH nano-halogen free flame retardant system.

[0022] Step 2. Mix

[0023] 93 parts by weight of homopolypropylene and 3 parts by weight of the above-mentioned prepared nano-CEPPA intercalated Zn 3 The Al-LDH nano-halogen-free flame retardant system is mixed in a twin-screw extruder, the extrusion temperature is set at 180°C, the vacuum degree is -0.08Pa, and the speed of the main engine is 240r / min.

[0024] The...

Embodiment 2-6

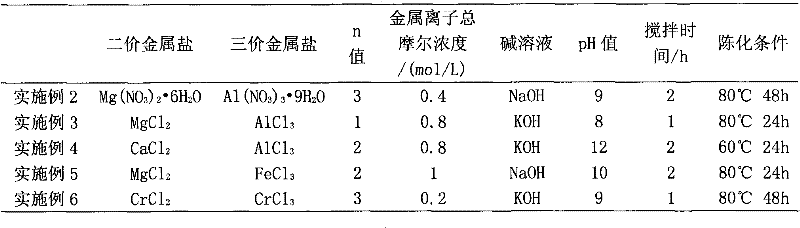

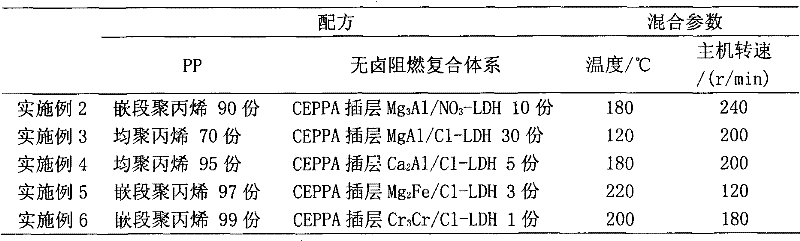

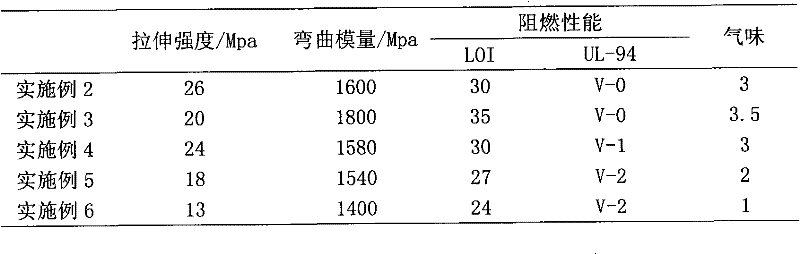

[0026] The specific implementation steps are consistent with Example 1, the difference lies in different raw materials and parameter settings, see Table 1 and Table 2 for details. The performance test results are shown in Table 3.

[0027] Table 1 Preparation of nano-halogen-free flame retardant system (step 1)

[0028]

[0029] Table 2 Mixing (step 2)

[0030]

[0031] Note: the parts in the table refer to parts by weight

[0032] Table 3 Performance test results

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com