Method for preparing conductive composite atomic oxygen protective coating ITO/MgF2

A composite atom and protective coating technology, which is applied in the field of aerospace, can solve problems such as microcracks, easy accumulation of static electricity, atomic oxygen erosion, etc., and achieve good protection performance, good flexibility, and improved work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

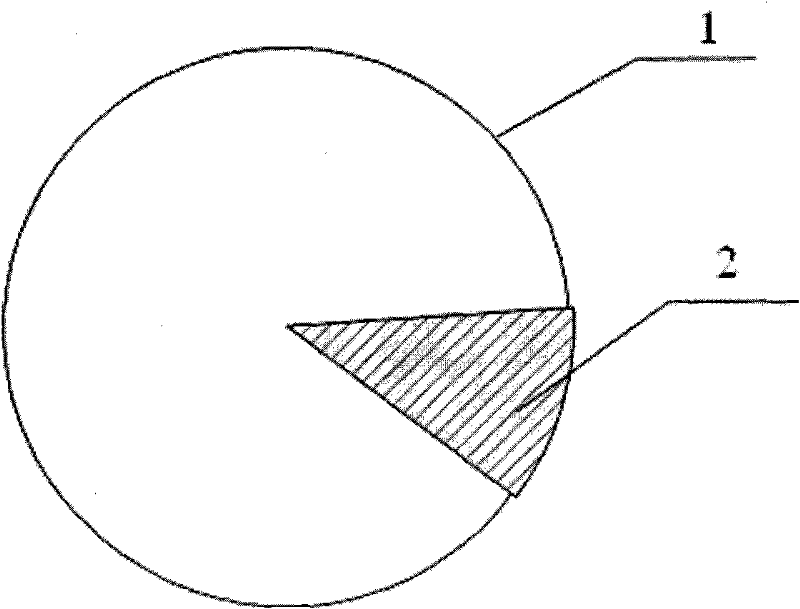

[0021] (1) Preparation of diameter 100mm, thickness 10mm, In 2 o 3 The mole percentage is 91%, SnO 2 The molar percentage is 9% of the ITO target;

[0022] (2) Prepare 4 pieces of MgF with a diameter of 100mm and a sector angle of 20° 2 Flake material, MgF 2 The purity is 99.9%;

[0023] (3) MgF was coated with conductive glue 2 The sheet material is evenly pasted on the ITO target;

[0024] (4) The ITO / MgF prepared in (3) 2 The composite target is installed on the target base of the magnetron sputtering equipment, and the magnetron sputtering equipment is vacuumed to 2×10 -3 Pa, then enter Ar gas, turn on the power supply of the magnetron sputtering target, the target surface will generate glow discharge, and the Ar ion flow will affect the ITO / MgF 2 The target is bombarded, and ITO and MgF are sputtered from the target surface 2 , deposited on a Kapton substrate to obtain ITO / MgF 2 Conductive composite atomic oxygen protective coating; the deposition discharge powe...

Embodiment 2

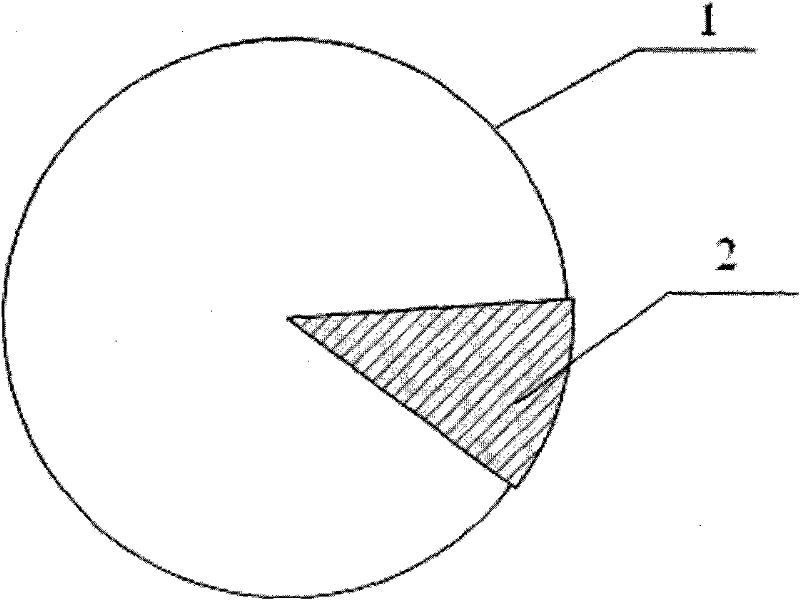

[0028] (1) Preparation of diameter 100mm, thickness 10mm, In 2 o 3 The mole percentage is 91%, SnO 2 The molar percentage is 9% of the ITO target;

[0029] (2) Prepare 6 pieces of MgF with a diameter of 100mm and a sector angle of 15° 2 Flake material, MgF 2 The purity is 99.9%;

[0030] (3) MgF was coated with conductive glue 2 The sheet material is evenly pasted on the ITO target;

[0031] (4) The ITO / MgF prepared in (3) 2 The composite target is installed on the target base of the magnetron sputtering equipment, and the magnetron sputtering equipment is vacuumed to 2×10 -3 Pa, then enter Ar gas, turn on the power supply of the magnetron sputtering target, the target surface will generate glow discharge, and the Ar ion flow will affect the ITO / MgF 2 The target is bombarded, and ITO and MgF are sputtered from the target surface 2 , deposited on a Kapton substrate to obtain ITO / MgF 2 Conductive composite atomic oxygen protective coating; the deposition discharge powe...

Embodiment 3

[0035] (1) Preparation of diameter 100mm, thickness 10mm, In 2 o 3 The mole percentage is 91%, SnO 2The molar percentage is 9% of the ITO target;

[0036] (2) Prepare 5 pieces of MgF with a diameter of 100mm and a sector angle of 20° 2 Flake material, MgF 2 The purity is 99.9%;

[0037] (3) MgF was coated with conductive glue 2 The sheet material is evenly pasted on the ITO target;

[0038] (4) The ITO / MgF prepared in (3) 2 The composite target is installed on the target base of the magnetron sputtering equipment, and the magnetron sputtering equipment is vacuumed to 2×10 -3 Pa, then enter the Ar gas, turn on the power supply of the magnetron sputtering target, the target surface will generate a glow discharge, and the Ar ion flow will affect the ITO / MgF 2 The target is bombarded, and ITO and MgF are sputtered from the target surface 2 , deposited on a Kapton substrate to obtain ITO / MgF 2 Conductive composite atomic oxygen protective coating; the deposition discharge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com