Novel cathode lining structure for aluminum electrolysis cell

A technology of aluminum electrolytic cell and cathode lining, which is applied in the field of new aluminum electrolytic cell cathode lining structure, can solve the problems of increased electrolyte distance setting, aluminum liquid fluctuation, and increased voltage setting, so as to increase the current density , Reduce production power consumption, reduce the effect of level fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A new type of aluminum electrolytic cell cathode lining structure is improved and designed on the basis of the current common aluminum electrolytic cell cathode lining structure and materials, and its construction process can still be based on the current general aluminum electrolytic cell lining structure. requirements and standards.

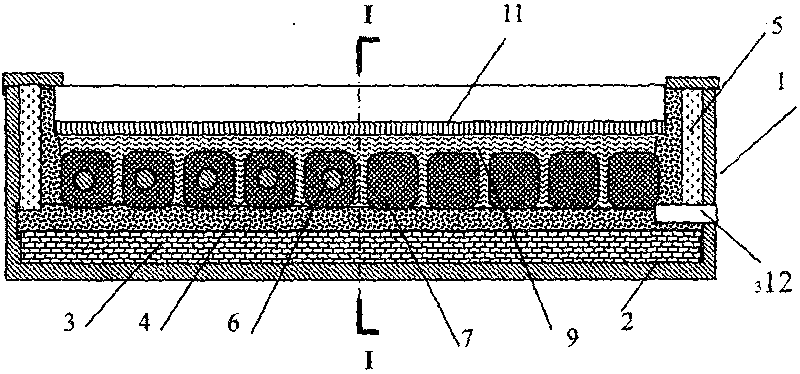

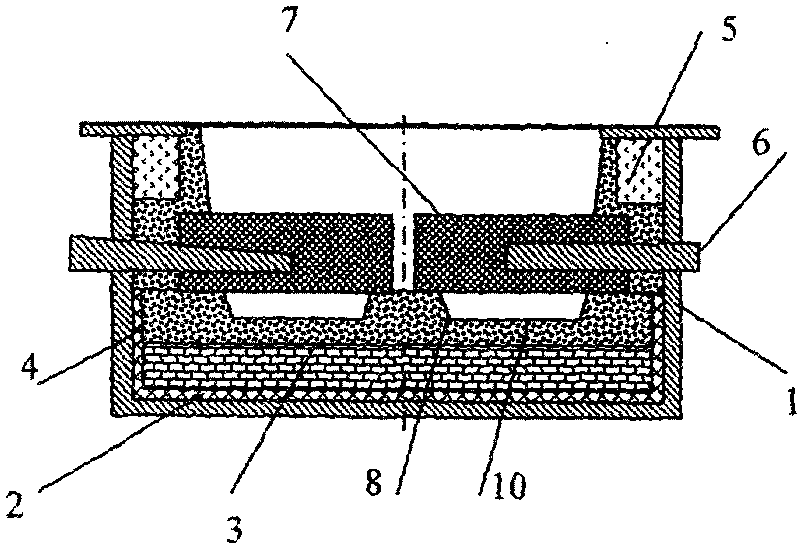

[0020] Such as figure 1 and figure 2 As shown, in Embodiment 1, the cathode carbon block (7) in the cathode lining of the aluminum electrolytic cell is rectangular, the cathode steel rod (6) is round, and the cathode steel rod (6) preferably has a certain taper , the two can be extruded and bonded by carbon cement, the cathode steel rod (6) and the cathode carbon block (7) can also be connected by threads, and conductive glue can be applied between the two to reduce the interface bonding resistance .

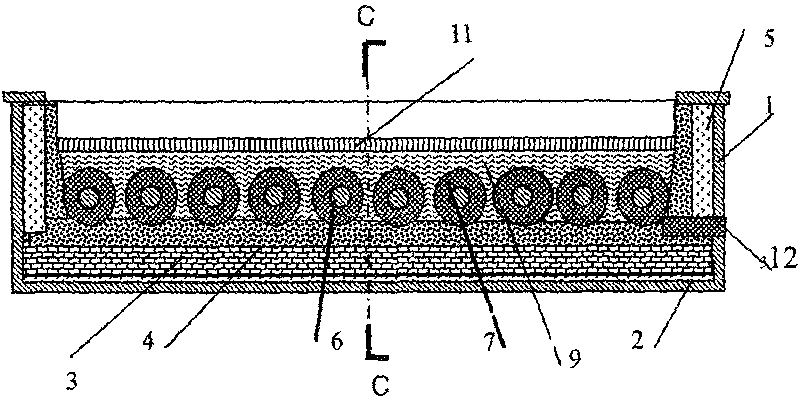

[0021] Such as image 3 and Figure 4 As shown, in another embodiment, the cathode carbon block (7) in the cathode lining of the al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com