Fabric used for making high absorbability dust free wiping cloth and manufacturing method thereof

A dust-free wiping cloth with high adsorption technology, which is applied to polyester fiber fabrics and its manufacture, fabrics with high adsorption dust-free wiping cloths and its manufacturing field, which can solve the problems of harsh process conditions, increased manufacturing difficulty, and easy Generate static electricity and other problems, achieve the effect of simple process, low cost, and less dust generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1, a kind of fabric that is used to make highly absorbent dust-free wiping cloth is the fabric obtained after alkali weight reduction pretreatment and hydrophilic finishing of ordinary polyester fabric.

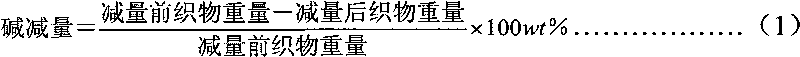

[0026] Step 1: Alkali reduction treatment

[0027] Cut ordinary polyester fabrics into 10cm square samples, put them into the aqueous solution of 20g / L sodium hydroxide and 0.8g / L hexadecyl trimethyl potassium bromide, bath ratio is 1:50, dipping temperature is 80 ℃, treated for 30min, the treated sample was washed with water to neutrality, and the alkali weight loss of the fabric was calculated according to the formula (1), and the alkali weight loss of the fabric treated in the present embodiment was 8.3wt%.

[0028]

[0029] Step 2: Polyhydroxyl polymer finishing

[0030] Put the above polyester fabric after the alkali reduction treatment into the aqueous solution of polyvinyl alcohol 2488 containing 5g / L, the water-bath ratio is 1:20, and adjust the ...

Embodiment 2~5

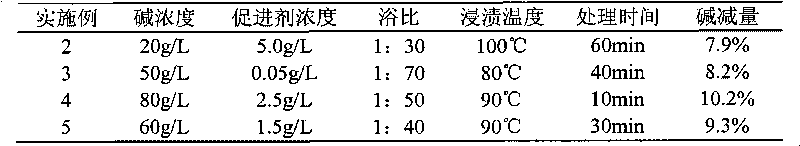

[0035] Embodiment 2~5, a kind of fabric that is used to make highly absorbent dust-free wiping cloth is the fabric obtained after alkali weight reduction pretreatment and hydrophilic finishing of ordinary polyester fiber fabric, and the processing steps are the same as in Example 1 , the specific process conditions and treatment results are shown in Tables 1 and 2 below.

[0036] Step 1: Alkali reduction treatment: Table 1

[0037]

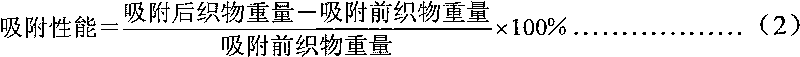

[0038] Step 2: Polyhydroxyl polymer finishing: Table 2

[0039]

Embodiment 6

[0040] Embodiment 6, a kind of fabric that is used for making highly absorbent dust-free wiping cloth is the fabric obtained after alkali weight reduction pretreatment and hydrophilic finishing of common polyester fiber fabric.

[0041] Step 1: Alkali reduction treatment

[0042] Cut ordinary polyester fabrics into 10cm square samples, put them into the aqueous solution of 20g / L sodium hydroxide and 0.8g / L hexadecyl trimethyl potassium bromide, bath ratio is 1:50, dipping temperature is 80 ℃, treated for 30min, the treated sample was washed with water to neutrality, and the alkali weight loss of the fabric was calculated according to the formula (1), and the alkali weight loss of the fabric treated in the present embodiment was 8.3wt%.

[0043] Step 2: Polyhydroxyl polymer finishing

[0044] At room temperature, use 30% acetic acid solution to adjust the pH of 1.5% polyvinyl alcohol 2488 aqueous solution to 3.0, apply polyvinyl alcohol aqueous solution on the fabric, and coat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com