Heterostructure photoanode for dye-sensitized solar cell and manufacturing method thereof

A solar cell and hierarchical structure technology, applied in photosensitive devices, capacitor electrodes, circuits, etc., can solve problems such as failure to achieve results, and achieve the effects of improving light utilization efficiency, improving photoelectric conversion efficiency, and enhancing charge transmission and separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

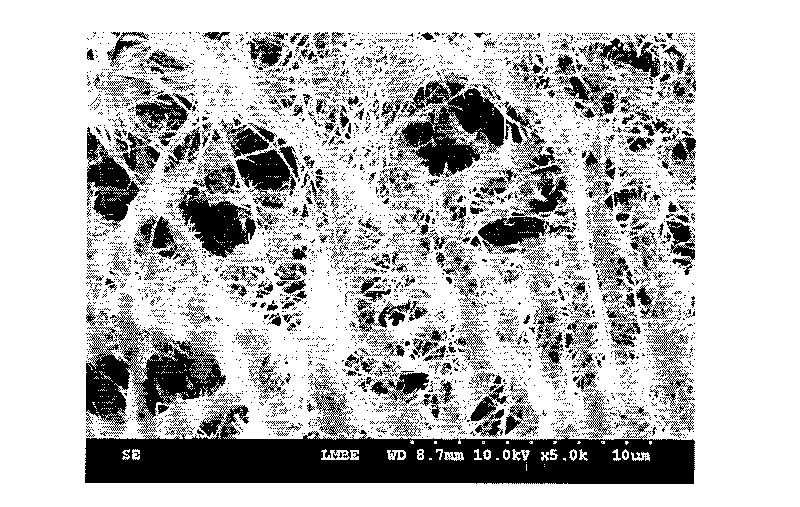

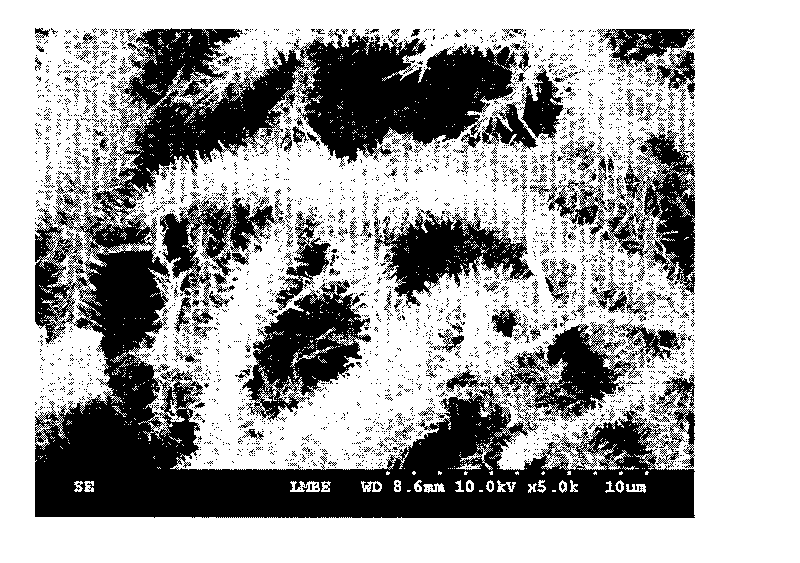

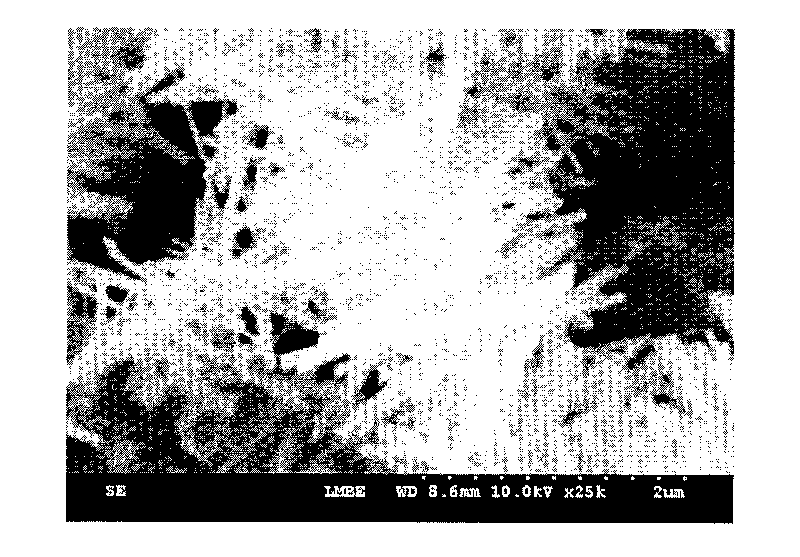

Image

Examples

Embodiment 1

[0029] a. Weigh 5 milliliters of butyl titanate and add it to 18 mL of absolute ethanol, mix and stir for 30 minutes, then add 0.3 milliliters of acetic acid, and continue to stir until a yellowish, transparent and clear solution is formed to obtain TiO sol solution;

[0030] b. Weigh 1.5 grams of zinc acetate and dissolve it in 10 milliliters of absolute ethanol, and mix and stir for 30 minutes to form a transparent and clear solution to obtain a zinc acetate solution;

[0031] c. Then 0.5 ml of titanium dioxide sol and 0.5 ml of zinc acetate were stirred for 60 minutes to form a yellow, transparent and clear solution to obtain a TiO2-zinc acetate mixed solution;

[0032] d. 2 ml of TiO2-zinc acetate solution was added to 10 ml of polyvinyl alcohol ethanol (absolute ethanol) solution of 30% mass concentration, and stirred for 3 hours to form a uniform and stable TiO2-zinc acetate / polyvinyl alcohol spinning solution ;

[0033] e. Place the TiO2-zinc acetate / polyvinyl alcohol ...

Embodiment 2

[0040] a. Weigh 10 ml of butyl titanate and add it to 20 ml of absolute ethanol, mix and stir for 30 minutes, then add 1.5 ml of acetic acid, and continue to stir until a slightly yellow, transparent and clear solution is formed to obtain TiO sol solution;

[0041] b. Weigh 0.5 gram of zinc acetate and dissolve it in 15 ml of absolute ethanol, and mix and stir for 30 minutes to form a transparent and clear solution to obtain a zinc acetate solution;

[0042] c. Then 1 ml of titanium dioxide sol and 1 ml of zinc acetate were stirred for 60 minutes to form a yellow, transparent and clear solution to obtain a TiO2-zinc acetate mixed solution;

[0043] d. 2 ml of TiO2-zinc acetate mixed solution was added to 5 ml of polyvinyl alcohol ethanol (absolute ethanol) solution of 40% mass concentration, and stirred for 3 hours to form uniform and stable TiO2-zinc acetate / polyvinyl alcohol spinning solution;

[0044] e. Place the TiO2-zinc acetate / polyvinyl alcohol spinning solution in a ...

Embodiment 3

[0050] a. Weigh 3 ml of ethyl titanate and add it to 10 ml of absolute ethanol, mix and stir for 30 minutes, then add 0.1 ml of acetic acid, and continue to stir until a yellowish, transparent and clear solution is formed to obtain TiO sol solution;

[0051] b. Weigh 2 grams of zinc acetate and dissolve it in 20 milliliters of absolute ethanol, mix and stir for 30 minutes to form a transparent and clear solution to obtain a zinc acetate solution;

[0052] c. Then 2 milliliters of titanium dioxide sol and 2 milliliters of zinc acetate were stirred for 60 minutes to form a yellow, transparent and clear solution to obtain a TiO2-zinc acetate mixed solution;

[0053] d. 3 milliliters of TiO2-acetate solution was added to 15 milliliters of polyvinylpyrrolidone ethanol (absolute ethanol) solution of 15% mass concentration, and stirred for 3 hours to form uniform and stable TiO2-zinc acetate / polyvinylpyrrolidone spinning solution;

[0054] e. Place the TiO2-zinc acetate / polyvinylpyr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Caliber | aaaaa | aaaaa |

| Caliber | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com