Preparation method of multi-junction solar cell

A technology of multi-junction solar cells and manufacturing methods, applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc., to achieve the effect of improving photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions of the present invention will be further described below in conjunction with embodiments.

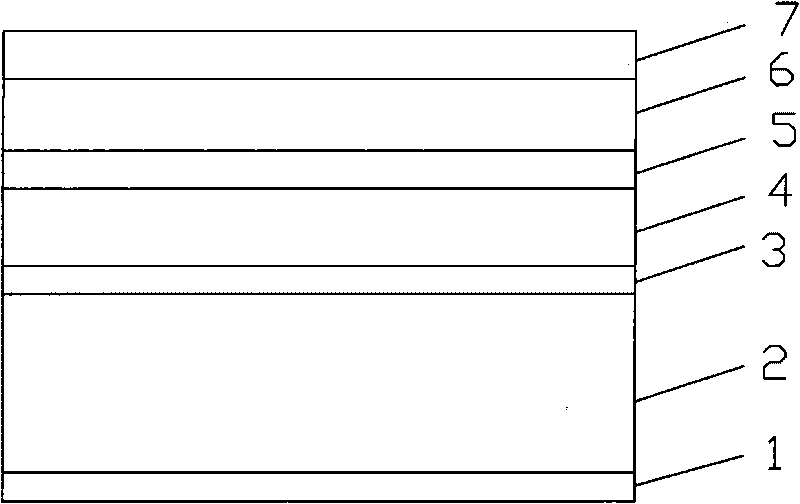

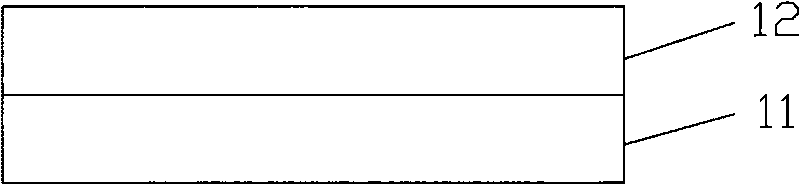

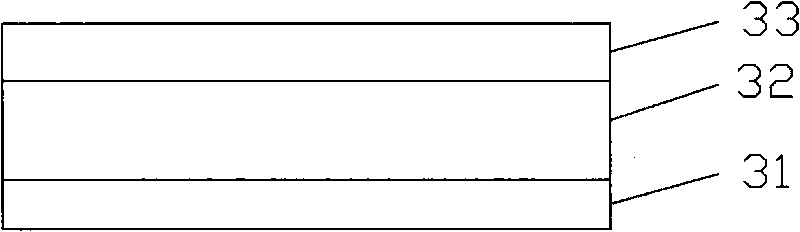

[0037] Such as Figure 1-4 Shown is the structure of a multi-junction solar cell with a Si / GaAs / InGaP three-layer structure. The bottom cell 1 is a Si PN junction cell, the middle cell 3 is a GaAs PN junction cell, and the top cell 5 is an InGaP PN junction cell. , Each sub-cell is directly grown on the silicon cell substrate.

[0038] Preparation method of multi-junction solar cell:

[0039] First, use 180μm thick P-type monocrystalline silicon to fabricate solar cells by chemical etching. The high-efficiency suede preparation is carried out in a magnetic field. That is, the monocrystalline silicon wafer is put into a suede preparation reactor equipped with a reaction solution. During the reaction, the suede preparation reactor is placed in a magnetic field below 15T. The ratio of the reaction solution is: sodium hydroxide or potassium hydroxide with a mass pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com