Integrated combined power supply of metal oxygen cell/hydrogen-oxygen fuel cell

An oxygen cell and fuel cell technology, applied in the direction of fuel cell type half cell and primary cell type half cell, etc., can solve problems such as corrosion, achieve the effects of less energy consumption, improved energy utilization rate, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

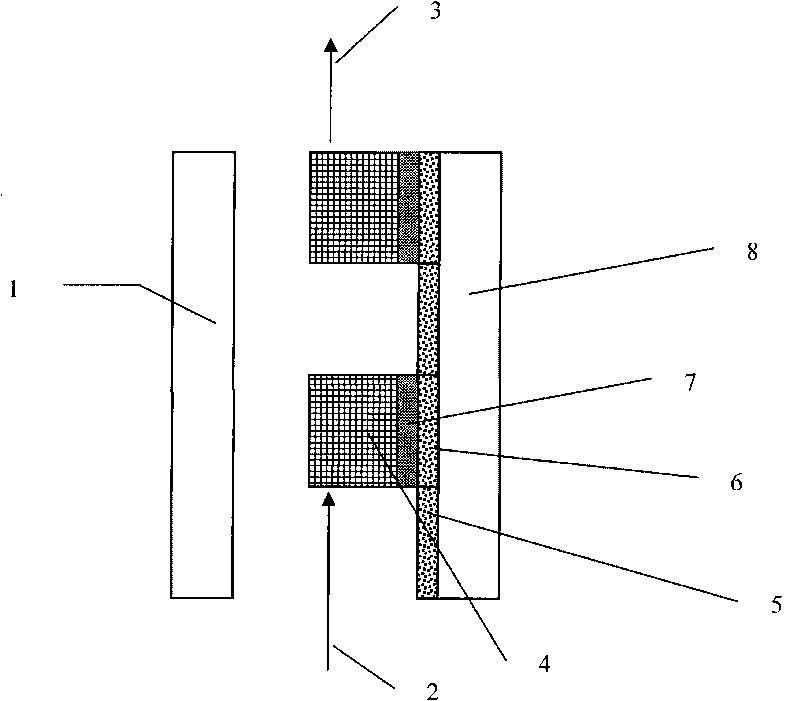

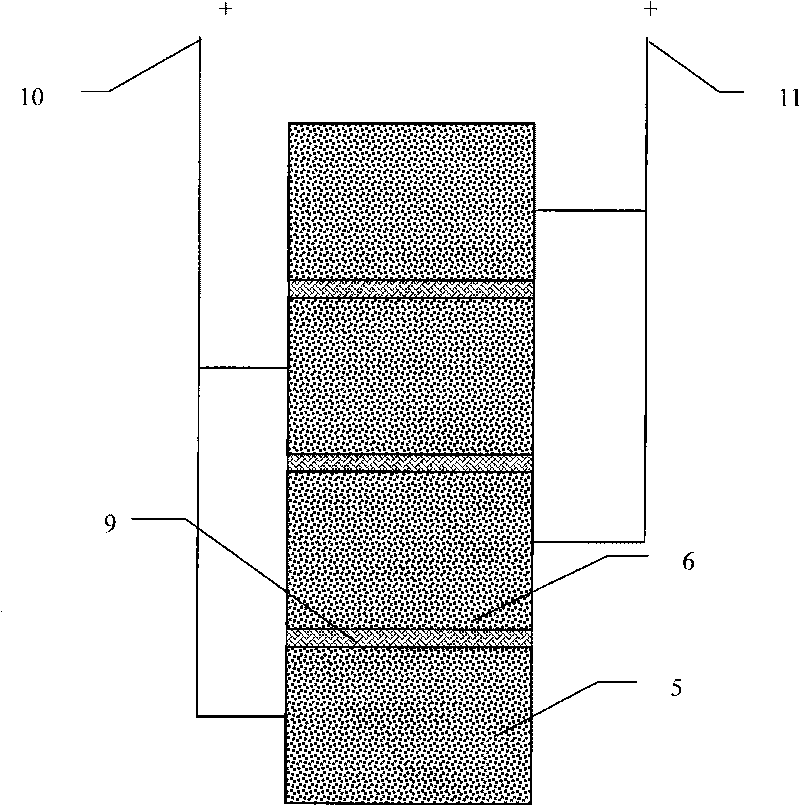

[0027] The metal anode 1 of the metal oxygen battery adopts AZ31 magnesium alloy anode with an area of 9.6cm 2 , the oxygen cathode cavity 8 is passed into air (oxygen therein is an oxidizing agent), H 2 -O 2 The fuel cell porous metal anode 4 adopts 110PPI porous nickel foam coated with Pd on the surface, with an area of 4.8cm 2 , Mg-O 2 battery cathode 5 and H 2 -O 2 The fuel cell cathode 6 is coated with MnO 2 The cathode of the catalyst, the diaphragm material 7 is a glass fiber woven mesh. The inlet electrolyte 2 is 3.5% NaCl solution at a temperature of 20°C, and the insulating material 9 is AB glue. From the battery inlet, the electrode presses Mg-O 2 Cathode 5 and H 2 -O 2 The cathode 6 is arranged once. Mg-O 2 battery cathode 5 and H 2 -O 2 The fuel cell cathode area is equal (both are 4.8cm 2 ). Mg-O 2 When the battery is not discharged, due to the small amount of hydrogen evolution, the H 2 -O 2 The open circuit voltage of the fuel cell is only...

Embodiment 2

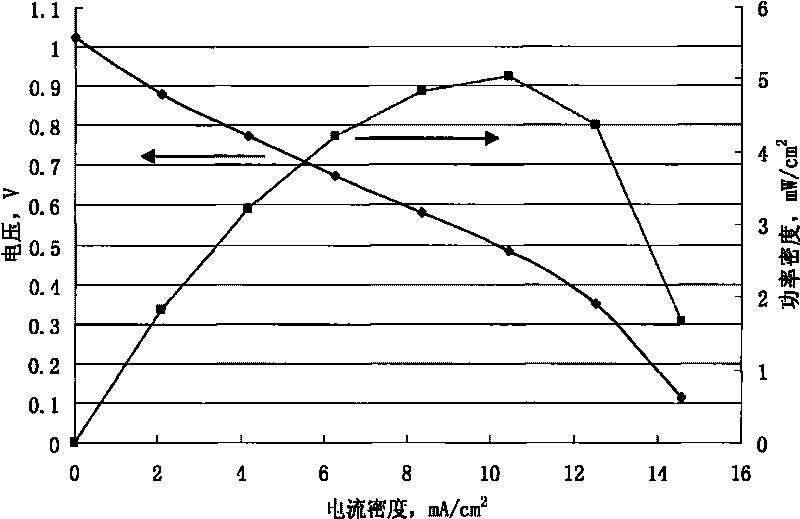

[0029] Mg-O 2 The area of cathode 5 is larger than H 2 -O 2 Fuel cell cathode 6 area, from cell inlet, electrode by Mg-O 2 Cathode 5 and H 2 -O 2 Fuel cell cathodes 6 are alternately arranged, (respectively 6.5cm 2 , 3cm 2 , 6.5cm 2 , 3cm 2 ), the metal anode area of the metal oxygen battery is 19cm 2 , H 2 -O 2 Fuel cell porous metal anode area is 6cm 2 . Other conditions are with embodiment 1. In Mg-O 2 Battery 23mA / cm 2 During constant current discharge, H 2 -O 2 Battery performance such as Figure 4 shown.

[0030] Mg-O 2 Current density 23mA / cm 2 When discharging with constant current, its output power is 300mW. After 5 minutes of discharge in a magnesium-oxygen battery, the H 2 -O 2 When the fuel cell anode potential gradually rises to 1.15V, start testing H 2 -O 2 Fuel cell discharge current-voltage curve ( Figure 4 ). h 2 -O 2 Battery current density 23mA / cm 2 When discharging, the maximum power density reaches 12.6mW / cm 2 , the reco...

Embodiment 3

[0033] The metal anode 1 of the metal oxygen battery adopts the anode with a purity of 99.96% Al, and the electrolyte uses 4N NaOH and 0.05M Na 2 SnO 3 Solution, other conditions are with embodiment 2.

[0034] Al-O 2 When the battery is not discharged, because Al has a certain corrosion in 4N NaOH solution, H 2 -O 2 The open circuit voltage of the fuel cell can reach 0.86V. Al-O 2 Battery current density 23mA / cm 2 When discharging with constant current, its output power is 321mW. in Al-O 2 After the battery is discharged for 5 minutes, the H 2 -O 2 When the open circuit voltage of the fuel cell gradually rises to 1.21V, start testing H 2 -O 2 Fuel cell discharge current-voltage curve ( Figure 5 ). h 2 -O 2 Fuel cell current density 25mA / cm 2 When discharging, the power density reaches 19.3mW / cm 2 , the recoverable energy is 115.8mW, accounting for Al-O 2 36.1% of battery power generation. Al-O 2 Battery at 23mA / cm 2 During electric dense discharge, the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com