Electric vehicle brushless motor controller

A brushless motor and controller technology, applied in the direction of single motor speed/torque control, etc., can solve the problems of large motor noise, small improvement in speed increase range, low cost performance, etc., to achieve improved service life, comfortable riding, and The effect of high operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

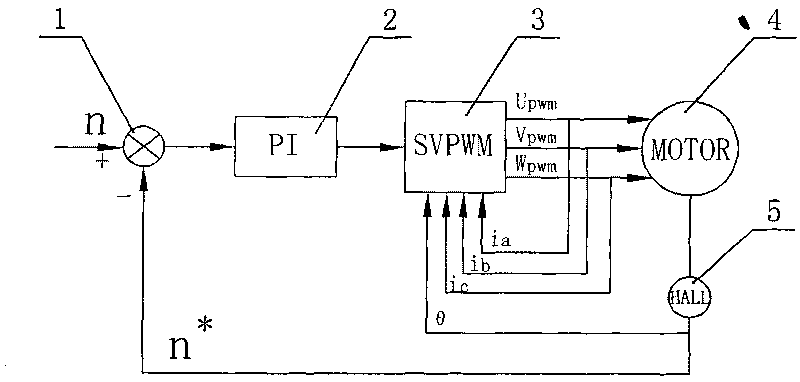

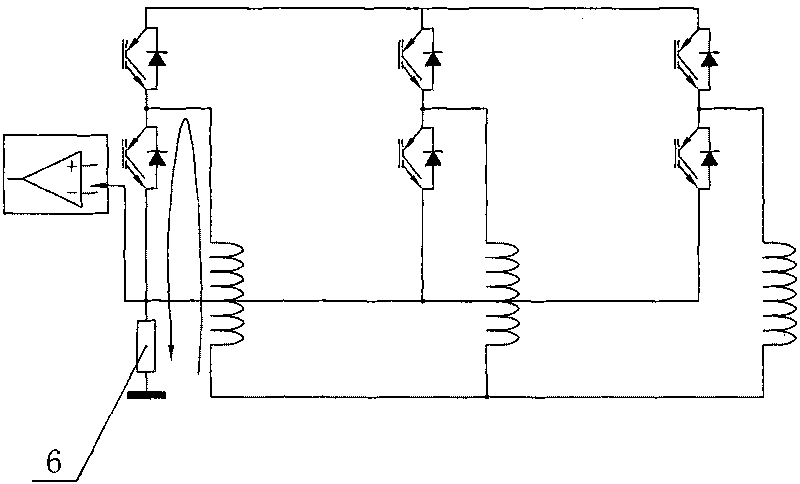

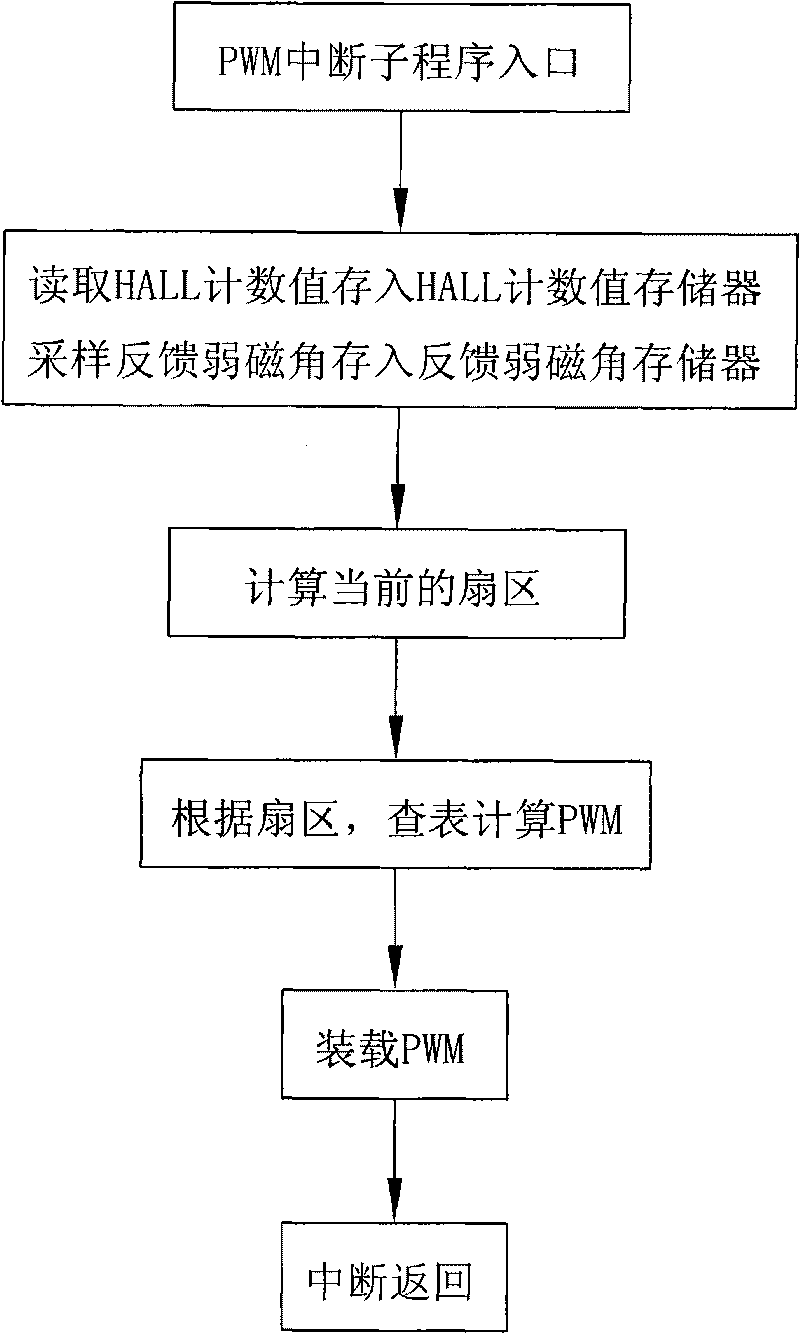

[0021] Such as figure 1 As shown, the brushless motor controller for an electric vehicle includes an error detector 1, a SVPWM motor vector controller 3, a PI control unit 2, a field weakening angle sampling unit, a current sampling unit, and a rotational speed sampling unit 5. The PI control unit 2 The output is connected to the input of the SVPWM motor vector controller 3, the output of the SVPWM motor vector controller 3 is connected to the motor 4, the SVPWM motor vector controller 3 is provided with a field weakening angle and current feedback to form an inner closed-loop control, and the output of the motor speed sampling unit 5 and The signal of the handle is connected with the error detector 1 to form the outer closed-loop control of the speed. The current sampling element in the current sampling unit is copper wire. The schematic diagram is as follows: figure 2 As shown, the rotational speed sampling element is a HALL sensor. Wherein the SVPWM motor vector controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com