Solar light-electricity-heat integrated intelligent bulk curing barn

A technology of solar energy and curing barn, which is applied in the fields of tobacco preparation, application, and tobacco, can solve the problems of inability to produce very effective results, difficult to promote, and high failure rate, so as to reduce the consumption of non-renewable resources, expand the scope of application, and improve the The effect of baking quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

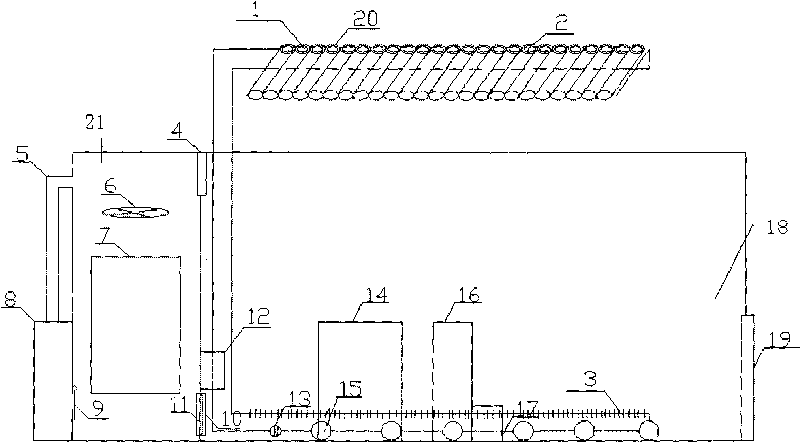

[0019] figure 1 Middle: 1 solar collector, 2 superconductor, 3 radiator, 4 return air outlet of baking room, 5 air inlet pipe of separator, 6 fan, 7 coal stove, 8 steam-water separator, 9 outlet of steam-water separator, 10 oven Room air inlet, 11 electric heating pipe, 12 heat pump unit indoor unit, 13 oil pump, 14 automatic control system, 15 liquid storage pipe, 16 heat pump unit outdoor unit, 17 step-up regulator, 18 smoke chamber, 19 door, 20 Vacuum tube, 21 hot air chambers.

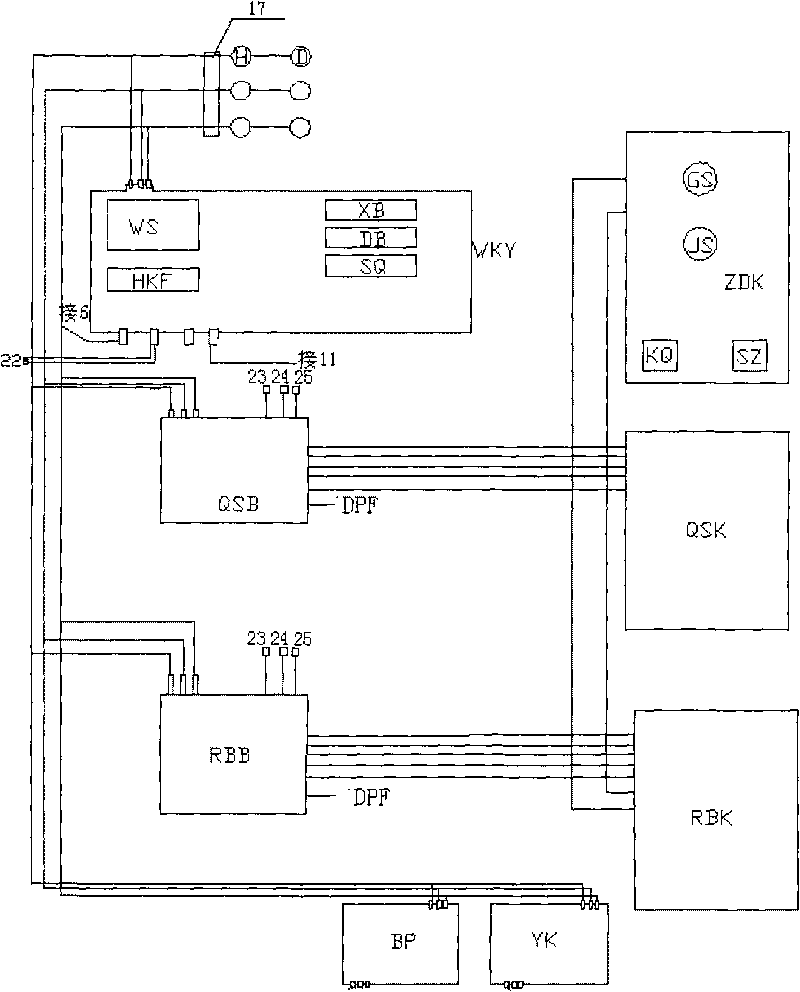

[0020] figure 2 Middle: 22 temperature and humidity probes, 23 heat pump unit outlet temperature probes, 24 high-voltage probes, 25 low-voltage probes, H: mutual inductor D: power supply WKY: temperature controller WS: temperature setting CB: over-temperature alarm DB: low-temperature alarm SQ : Manual and automatic switching HKF: Baking mode selection QSB: Steam-water separator host control board RBB: Heat pump host control board BP: Inverter YK: Oil pump controller ZDK: Automatic operation con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com