Method for photocatalytic reduction of carbon oxide

A technology of carbon dioxide and photocatalysis, applied in the direction of carbon monoxide, chemical instruments and methods, separation methods, etc., can solve the problems of poor adsorption effect, achieve the effect of increasing adsorption capacity, improving adsorption competitiveness, and improving adsorption power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

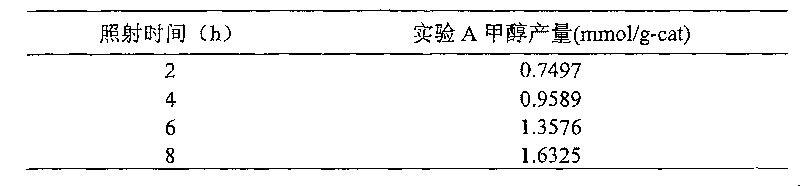

[0024] This embodiment is a blank experiment A of the photocatalytic reaction, that is, a photocatalytic reaction experiment under the condition of generating a hydrate-free slurry.

[0025] The reaction kettle of the photocatalytic reaction of the present embodiment is a fully transparent high-pressure sapphire kettle (produced by DBROBINSON, Canada), with a volume of 78ml, wherein anatase TiO 2 Catalyst 0.15g, deionized water 40ml, adopting light source is 150W mercury light lamp, feeds carbon dioxide, and the purity of this carbon dioxide gas sample is 99.5% (produced by Beijing Hepu Beifen Gas Co., Ltd.). Put carbon dioxide into the above-mentioned transparent high-pressure sapphire kettle, turn on the light source and adjust the magnetic stirring speed to 15r / min to start the photocatalytic reaction, keep the reaction pressure at 2.0MPa, and the reaction temperature at 4.6°C. Lighting time was controlled as 2h, 4h, 6h, 8h respectively.

[0026] It was determined that the...

Embodiment 2

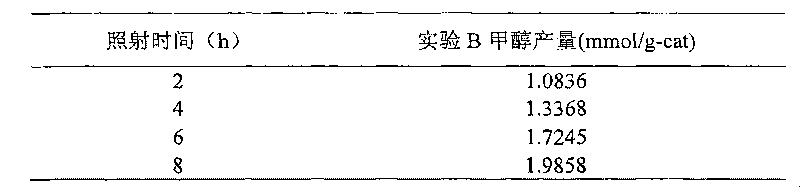

[0030] Experiment B was implemented in a photocatalytic reactor to realize the photocatalytic reaction of hydrates under heterogeneous equilibrium conditions.

[0031] The conditions of experiment B are: the reaction kettle is a fully transparent high-pressure sapphire kettle (produced by DBROBINSON, Canada), with a volume of 78ml, and anatase TiO 2 Catalyst 0.15g, deionized water 40ml, adopting light source is 150W mercury light lamp, feeds carbon dioxide, and the purity of this carbon dioxide gas sample is 99.5% (produced by Beijing Hepu Beifen Gas Co., Ltd.). Start the magnetic stirring motor at a speed of 15r / min, keep the reaction pressure at 2.0MPa, control 4°C to hydrate carbon dioxide to obtain a hydrate slurry, and maintain the multiphase equilibrium state. At this time, keep the temperature and pressure constant, and turn on the light source to start the light. Catalytic reaction, the light time is 2h, 4h, 6h, 8h respectively.

[0032] It was determined that the liq...

Embodiment 3

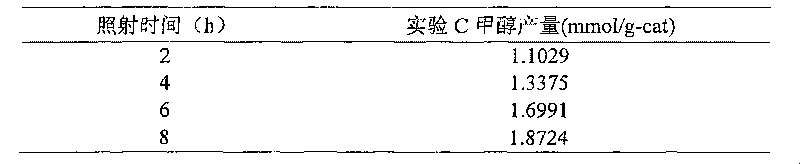

[0036] Experiment C was implemented in the photocatalytic reactor to realize the photocatalytic reaction under the condition of slow decomposition of hydrate.

[0037] The condition of experiment C is that the reaction kettle is a fully transparent high-pressure sapphire kettle (produced by DBROBINSON, Canada), with a volume of 78ml, and anatase TiO 2 Catalyst 0.15g, deionized water 40ml, adopting light source is 150W mercury light lamp, feeds carbon dioxide, and the purity of this carbon dioxide gas sample is 99.5% (produced by Beijing Hepu Beifen Gas Co., Ltd.). Start the magnetic stirring motor at a speed of 15r / min, keep the reaction pressure at 2.0MPa, first control at 4°C to generate hydrate slurry, and reach multiphase equilibrium, keep the pressure at 2.0MPa, raise the temperature to 4.6°C, turn on the light source, The photocatalytic reaction is carried out in the state of slow decomposition, and the light time is 2h, 4h, 6h, 8h respectively.

[0038] It was determin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com