Self-focusing laser welding device

A laser welding and self-focusing technology, used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of insufficient flexibility, easy damage to the focus spot of the focusing lens, and high cost of the lens group.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment example, the present invention will be further described:

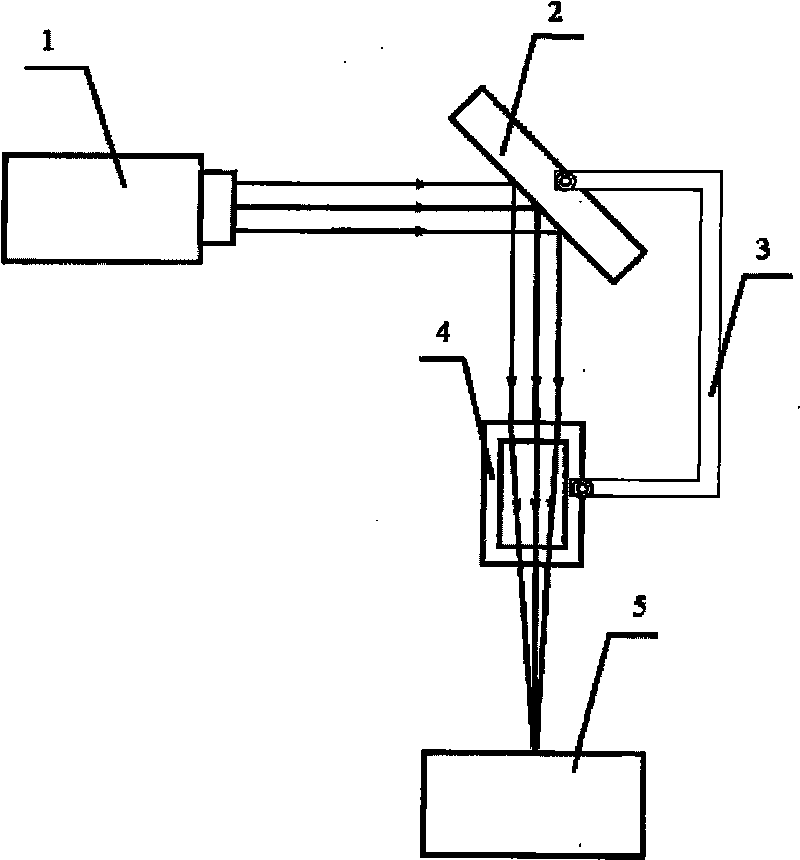

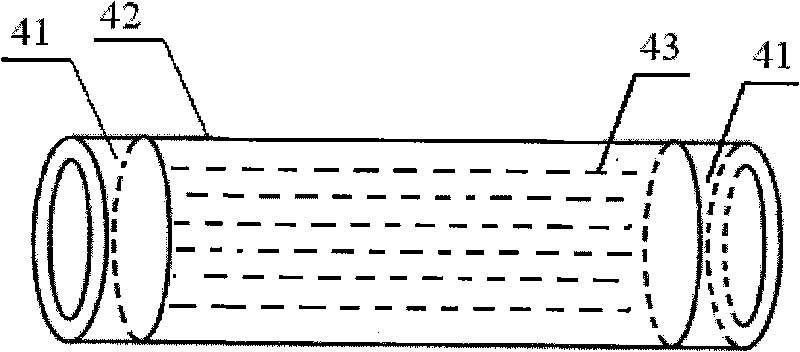

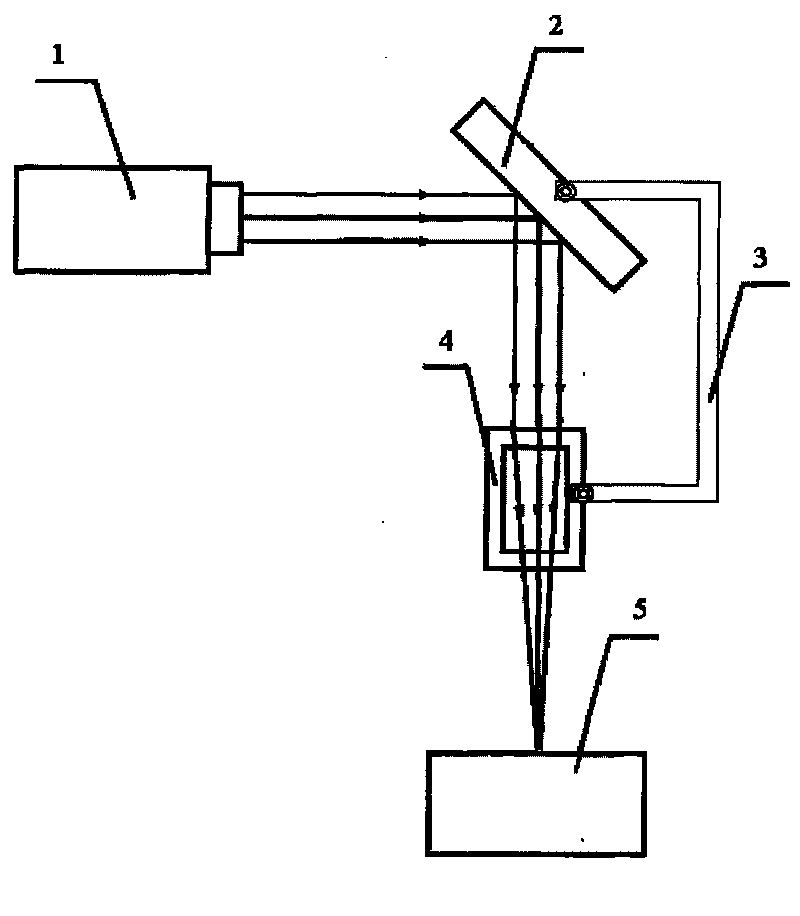

[0017] See attached figure 1 , a self-focusing laser welding device, its structure is: a laser 1, a total reflection plate 2, an I-shaped bracket 3, a laser self-focusing tube 4 and a workbench 5. The laser is a Nd:YAG pulsed laser with a laser wavelength of 1062nm. The total reflection plate is a silver-plated high-reflection glass plate with a reflectivity of 99.99%. The I-shaped bracket is made of steel with a width of 3cm and a thickness of 5mm; The quartz incident window of the focusing tube has a thickness of 2 mm and a diameter of 2 cm; the diameter of the glass tube is 2 cm, the thickness of the tube wall is 1 mm, and the tube length is 2 cm; liquid CS is injected into the glass tube 2 , whose linear refractive index and nonlinear coefficient are respectively

[0018] no 0 =1.62,n 2 =1.3×10 -11 esu. At this time CS 2 The refractive ind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Tube wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com