Method for preparing white carbon black by gas phase method and used equipment thereof

A fumed silica and equipment technology, applied in climate sustainability, sustainable manufacturing/processing, silica and other directions, can solve the problems of difficult comprehensive utilization of thermal energy, continuous production, and reduced deacidification capacity, etc. Achieve efficient use of energy, improve product quality, and minimize surface area fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

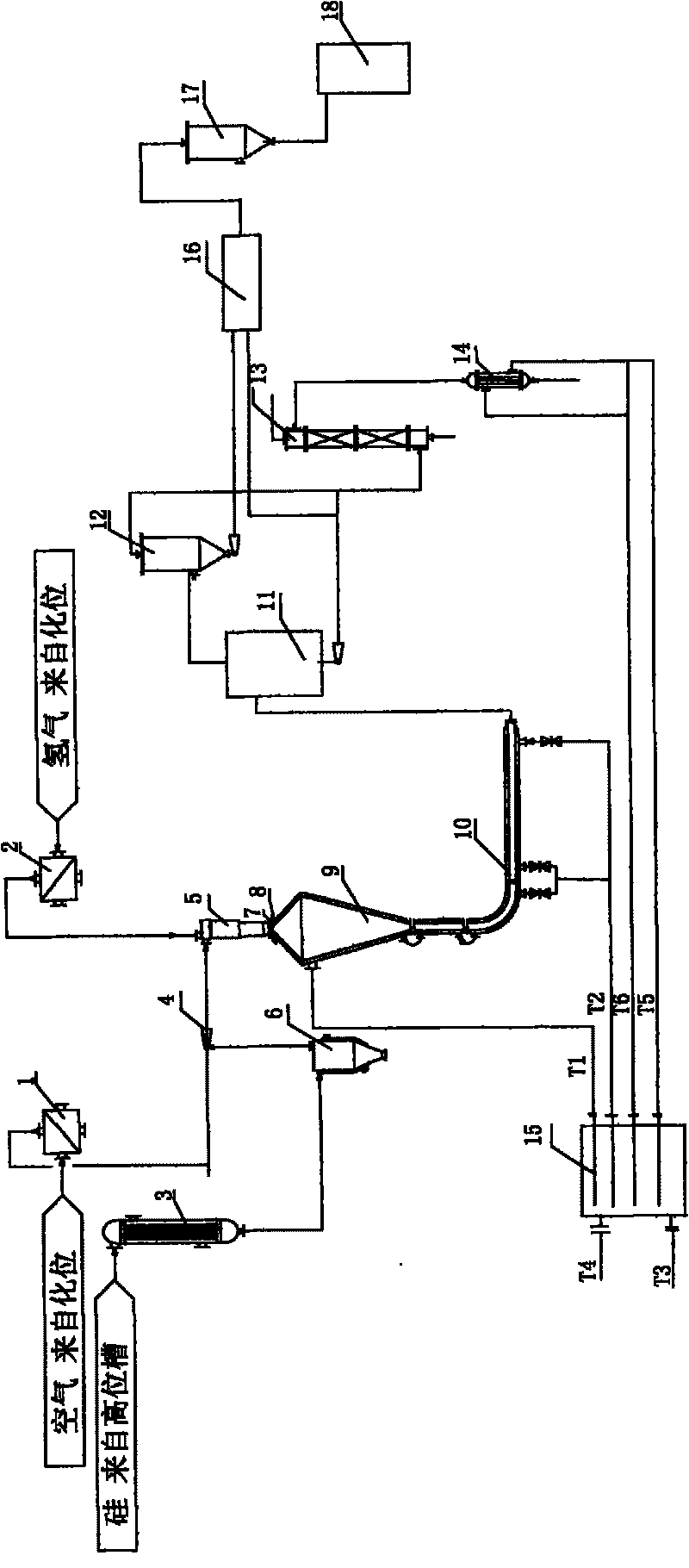

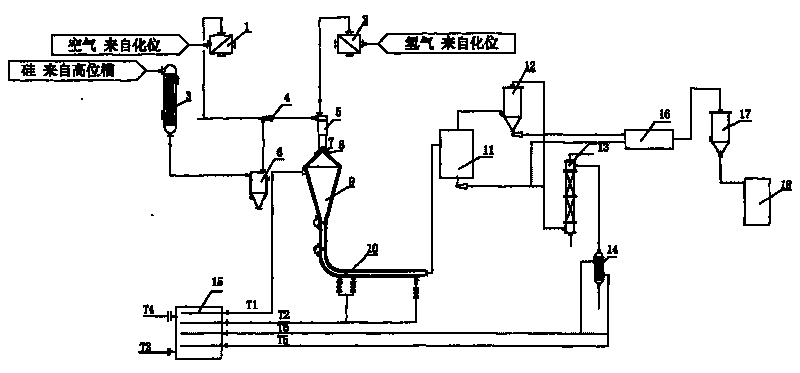

[0037] According to the ratio of 2: (0.8-1.1): (20-25): (2-3), silicon tetrachloride, air and hydrogen are accurately measured respectively, so that silicon tetrachloride is preheated by silane preheater 3 and then heated by The silane reboiler 6 is vaporized and then mixed with the air from the air preheater 1 in the mixing venturi 4, the mixed raw material is mixed with the hydrogen from the hydrogen preheater 2 in the injection device 5 and passed through the injection device 5 The nozzles are sprayed into the high-temperature hydrolysis furnace 9 to carry out the high-temperature hydrolysis reaction, generating a large amount of gas-phase silica gas-solid mixture and releasing a large amount of heat. Wherein the injection device 5 and the high-temperature hydrolysis furnace 9 are connected through a flange seal, and no air is supplied during the injection mixing stage and the high-temperature hydrolysis stage. The gas-solid mixture discharged from the high-temperature hydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com