Process for producing resorcinol by continuously hydrolyzing m-phenylenediamine

A technology of m-phenylenediamine and resorcinol, which is applied in the field of continuous hydrolysis of m-phenylenediamine to produce resorcinol, which can solve the problems of reduced reaction yield and product quality, long storage time of hydrolyzed materials, and high energy consumption of external input. problems, to achieve a high degree of device intensification, solve the problem of decomposition and deterioration, and enhance competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The hydrolysis reaction and batching system use nitrogen to replace the air in the system device.

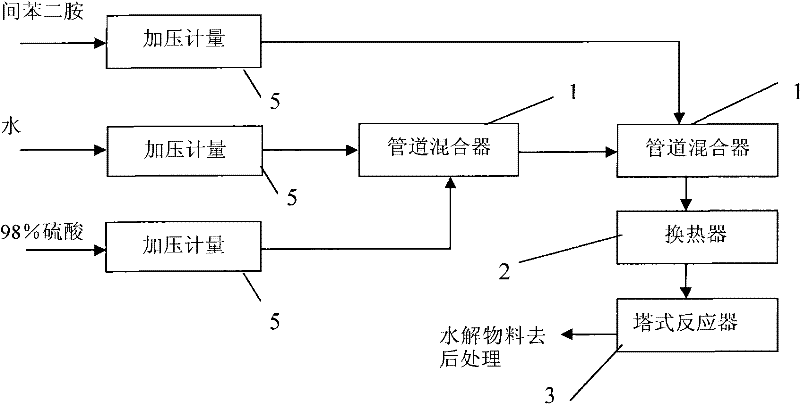

[0050] Continuously convey metered 98% sulfuric acid, molten m-phenylenediamine and demineralized water (or distilled water) with a booster pump, wherein, 98% sulfuric acid and water pass through a first-stage pipeline mixer to prepare 12% dilute sulfuric acid, dilute sulfuric acid Prepare m-phenylenediamine sulfate solution with m-phenylenediamine by secondary pipeline mixer, the flow of m-phenylenediamine, 98% sulfuric acid, water are respectively 0.77kg / min, 2.075kg / min, 10.21kg / min, determine The molar ratio of m-phenylenediamine, sulfuric acid and water is 1:2.0:60.

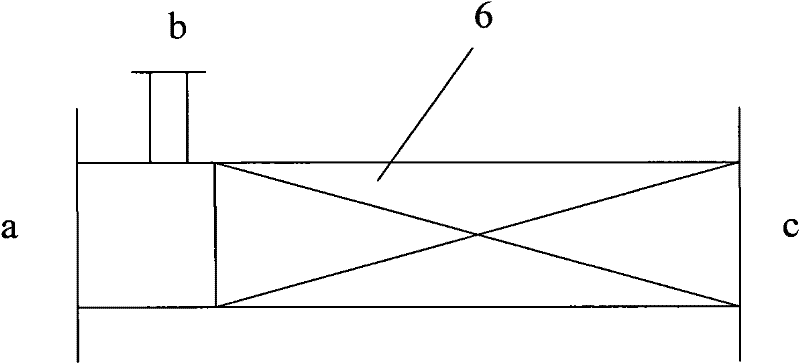

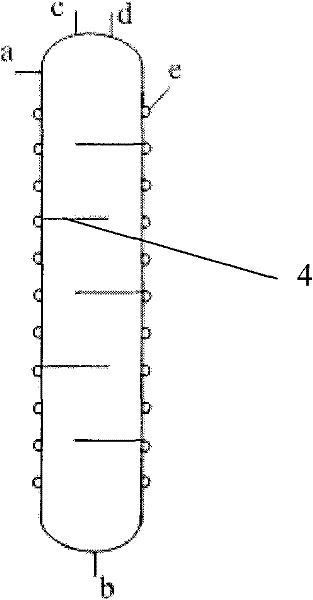

[0051] Hydrolysis using 2m 3 A tower reactor with an aspect ratio of 4.2 and five baffles inside. The m-phenylenediamine sulfate aqueous solution prepared by metering and pressurizing m-phenylenediamine, sulfuric acid and water is heated to 237°C through a heat exchanger, and then continuously pressed...

Embodiment 2

[0054] According to the method described in Example 1, the difference is that the molar ratio of m-phenylenediamine, sulfuric acid, and water is 1:1.8:80, the hydrolysis reaction temperature is 242° C., and the hydrolysis reaction residence time is 135 minutes. The product purity is 99.4%, and the yield is 90.0%.

Embodiment 3

[0056] According to the method described in Example 1, the difference is that the molar ratio of m-phenylenediamine, sulfuric acid, and water is 1:2:100, the hydrolysis reaction temperature is 230° C., and the hydrolysis reaction residence time is 200 minutes. The product purity is 99.5%, and the yield is 91.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com