Biodegradable cationic polymer and application thereof

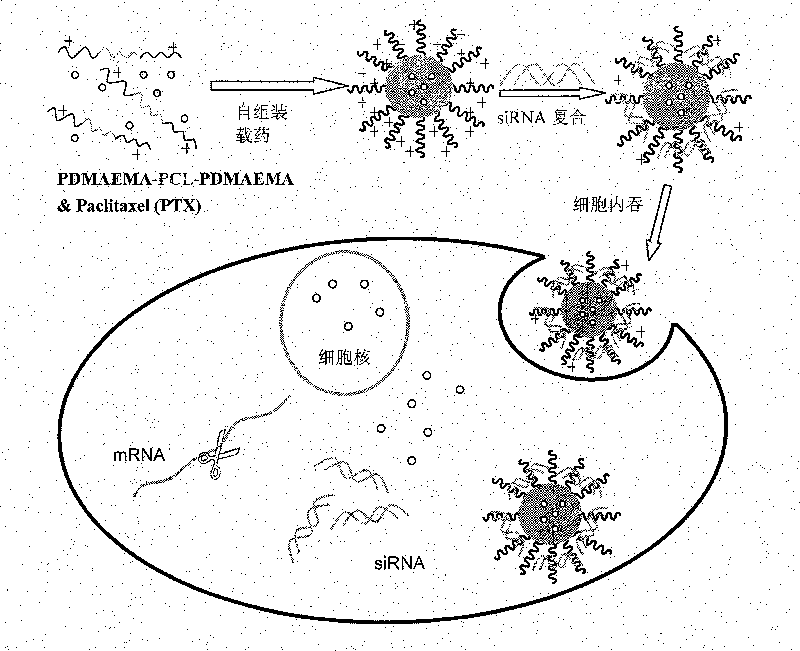

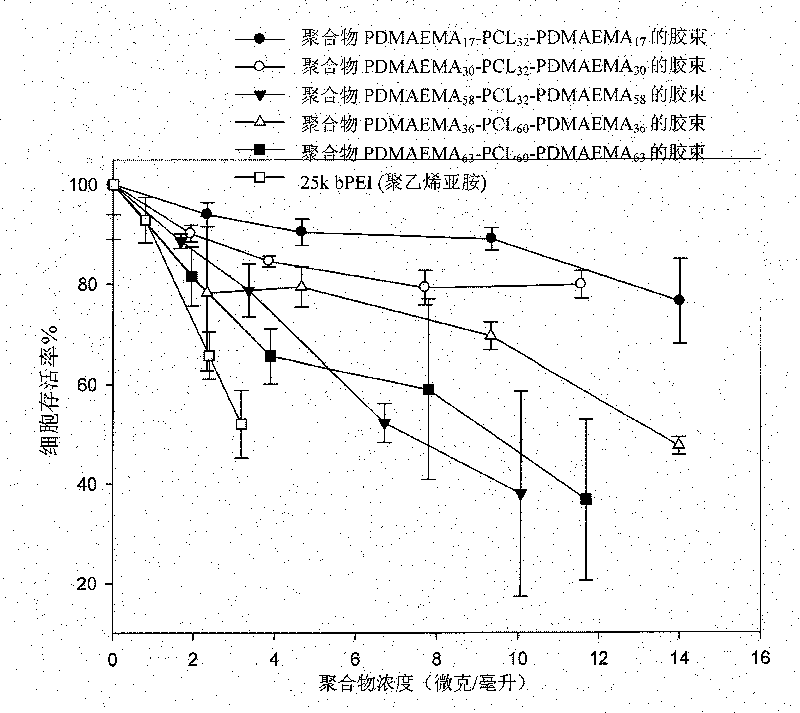

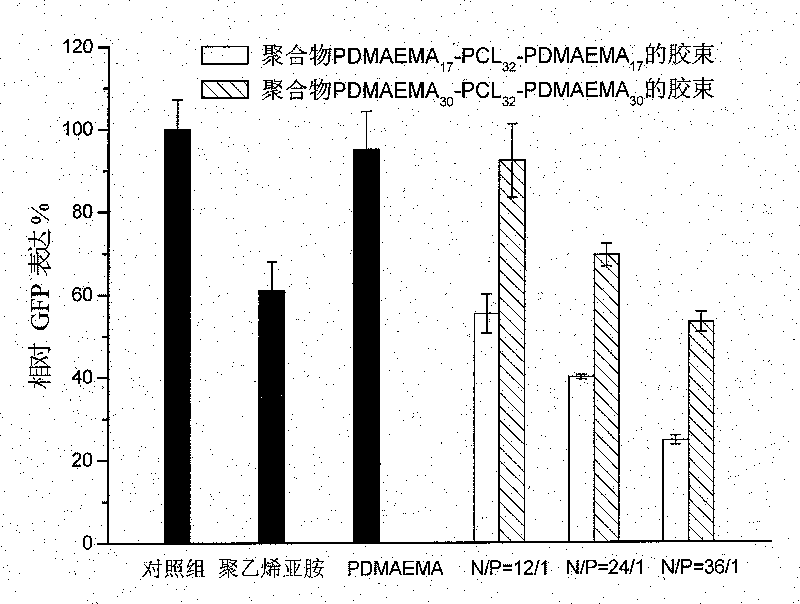

A cationic polymer, cationic technology, used in genetic material components, medical preparations with inactive ingredients, gene therapy, etc., can solve the problems of high toxicity in vivo, inability to compress siRNA well, low efficiency, etc., to strengthen the concentration of drugs. effect on symptoms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment one, RAFT polymerization obtains triblock copolymer PDMAEMA 17 -PCL 32 -PDMAEMA 17

[0036] Under argon protection, the initiator AIBN (1.0 mg, 6.2 μmol), the macromolecular RAFT reagent CPADN-PCL 32 -CPADN (0.13 g, 31 μmol), N,N-dimethylmethacrylate (DMAEMA) monomer (0.19 g, 1.24 mmol) and 1.5 mL of tetrahydrofuran were added to a 10 mL Schlenk vacuum-sealed bottle, and argon After aeration for 30 minutes, the bottle was placed in an oil bath at 60° C., stirred and reacted for 24 hours, precipitated in n-hexane, filtered, and vacuum-dried for 48 hours to obtain a triblock copolymer with a yield of 80%. NMR results show that its structure is PDMAEMA 17 -PCL 32 -PDMAEMA 17 . m n (GPC)=9200, M w / M n (GPC) = 1.15.

Embodiment 2

[0037] Embodiment two, RAFT polymerization obtains triblock copolymer PDMAEMA 58 -PCL 32 -PDMAEMA 58

[0038] Under the protection of argon, the initiator AIBN (1.0 mg, 6.2 μmol), the macromolecular RAFT reagent CPADN-PCL-CPADN (0.13 g, 31 μmol), N, N-dimethyl methacrylate monomer DMAEMA (0.71 g, 4.65mmol) and 1.5mL of tetrahydrofuran were added to a 10mL Schlenk vacuum-sealed bottle, and the bottle was placed in an oil bath at 60°C after passing argon for 30 minutes. After stirring and reacting for 24 hours, it was precipitated in n-hexane and filtered. , dried in vacuum for 48 hours to obtain a triblock copolymer with a yield of 72%. NMR results show that its structure is PDMAEMA 58 -PCL 32 -PDMAEMA 58 . m n (GPC)=21100, M w / M n (GPC) = 1.42.

Embodiment 3

[0039] Embodiment three, RAFT polymerization obtains triblock copolymer PDMAEMA 30 -PCL 32 -PDMAEMA 30

[0040] Under the protection of argon, the initiator AIBN (1.0 mg, 6.2 μmol), the macromolecular RAFT reagent CPADN-PCL-CPADN (0.13 g, 31 μ.mol), N, N-dimethyl methacrylate monomer DMAE MA (0.36g, 2.33mmol) and 1.5mL of tetrahydrofuran were added to a 10mL Schlenk vacuum-sealed bottle, and after 30 minutes of argon gas, the bottle was placed in an oil bath at 60°C. After stirring for 24 hours, the reaction was carried out in n-hexane Precipitate, filter, and vacuum dry for 48 hours to obtain a triblock copolymer with a yield of 75%. NMR results show that its structure is PDMAEMA 30 -PCL 32 -PDMAEMA 30 . m n (GPC)=14200, M w / M n (GPC) = 1.31.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com