Opposed-piston engine

A technology of opposed pistons and engines, applied in engine components, combustion engines, machines/engines, etc., can solve the problems of difficulty in improving the fuel efficiency of internal combustion engines, energy consumption, etc., to reduce fuel consumption rate and vibration degree, and save fuel The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

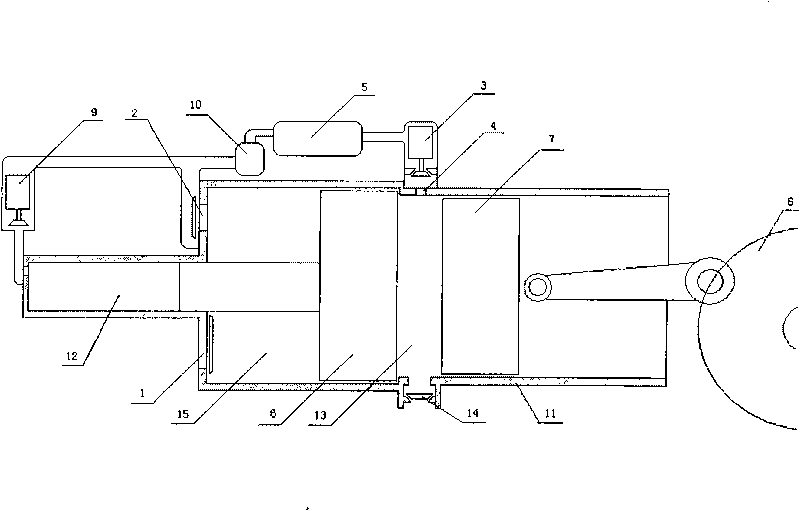

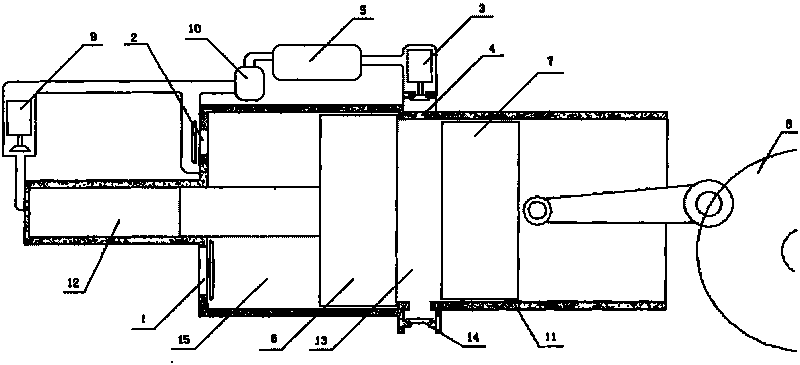

[0012] Such as figure 1 As shown, the opposed piston engine includes cylinder 11, working piston 6, crankshaft 8 and other components. The working piston 6 is installed in the cylinder and hinged to the crankshaft 8 through the connecting rod. Compressor piston 7 with the opposite movement direction; the end face of the cylinder body located on one side of the compressor piston 7 is provided with an intake valve 1 and an outlet valve 2, the intake valve 1 communicates with the atmosphere, and the compressor piston 7 forms an air chamber 15 with the end surface of the cylinder body , the cylinder 11 is provided with a mechanism that can reset the compression piston 7; the outlet valve 2 is connected with an air storage mechanism 5 for storing high-pressure gas through an oil-gas separation device 10; the middle part of the cylinder is a combustion chamber 13, and the combustion chamber 13 is provided with an inlet The air port 4, the exhaust port 14, the fuel injection device, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com