Air valve structure of overall cylinder cover of medium-power diesel engine

A diesel engine and power technology, applied in the direction of cylinder head, engine cooling, cylinder, etc., can solve the problem of cylinder head failing to meet design requirements, achieve good fuel economy, reduce harmful emissions, and improve combustion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

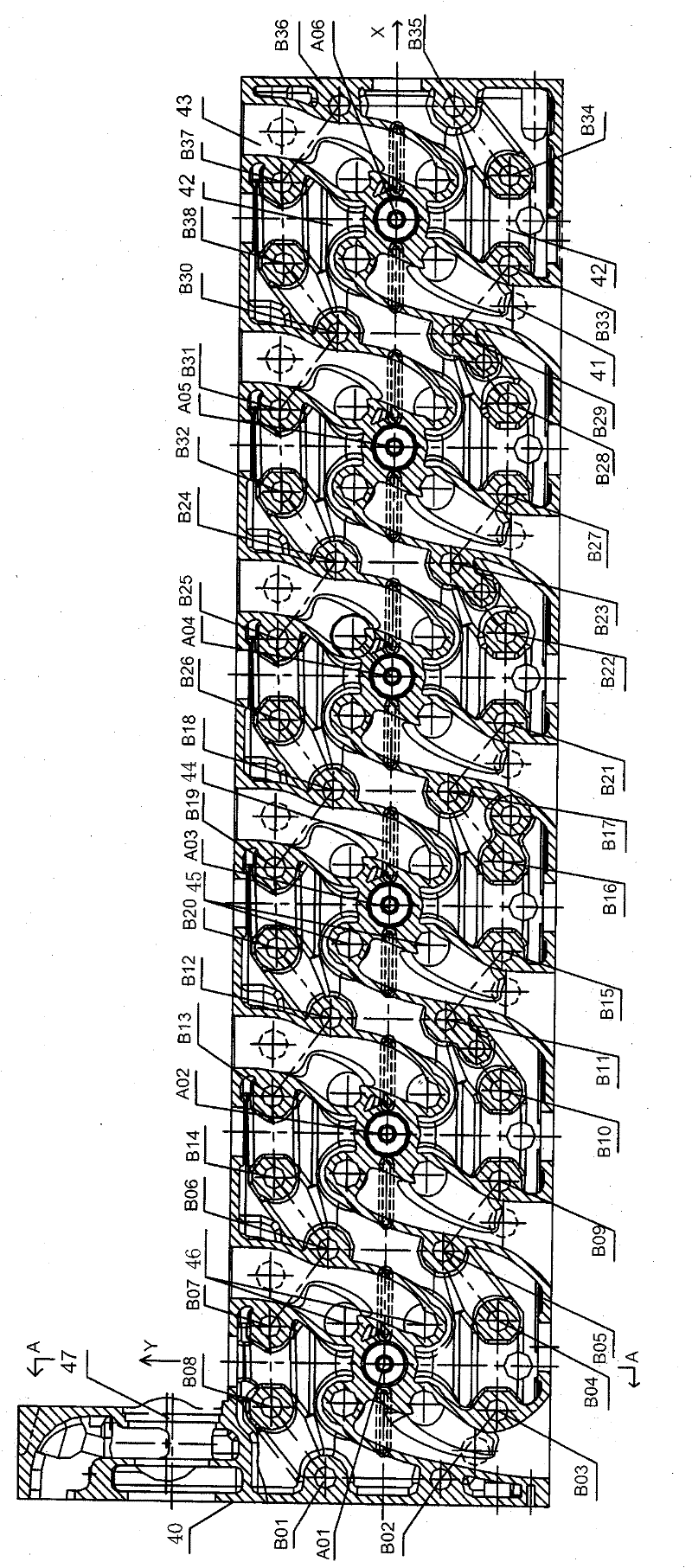

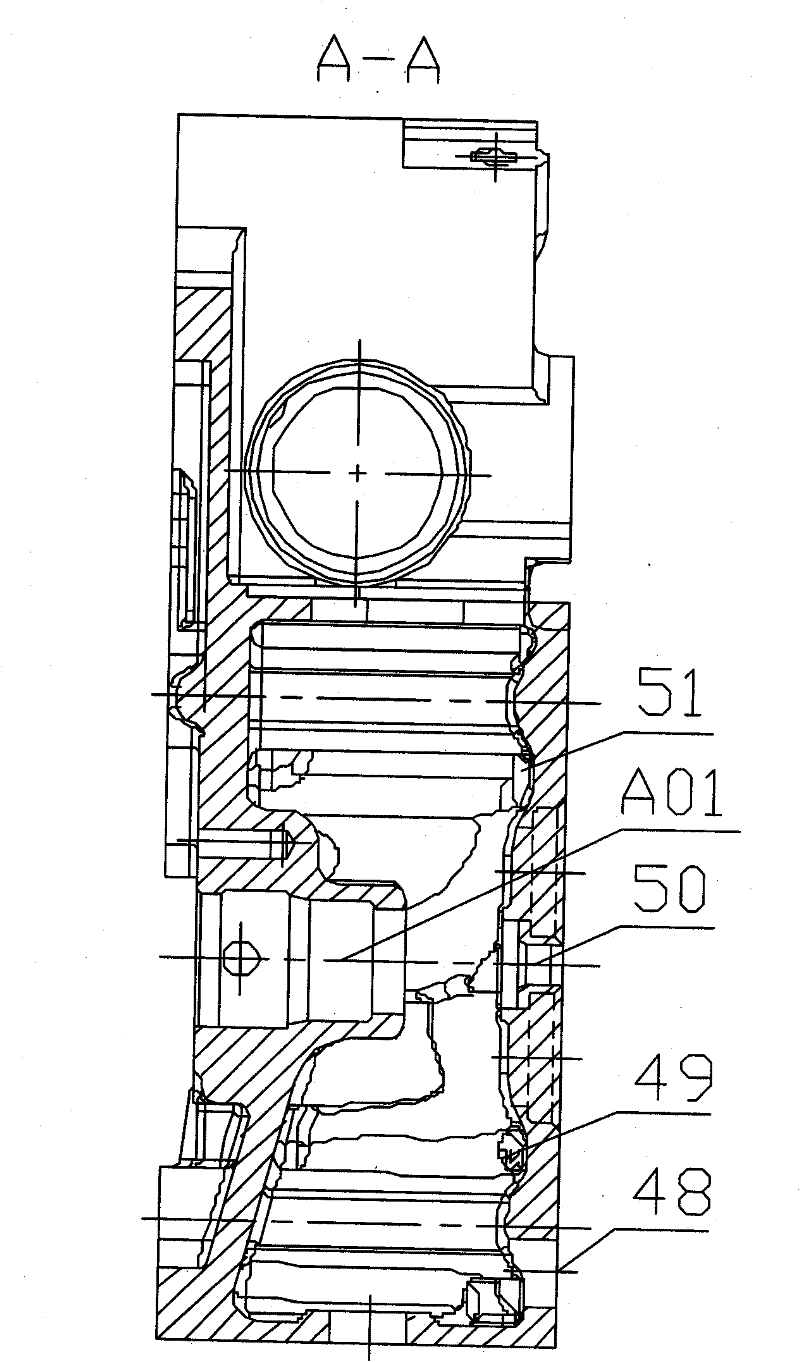

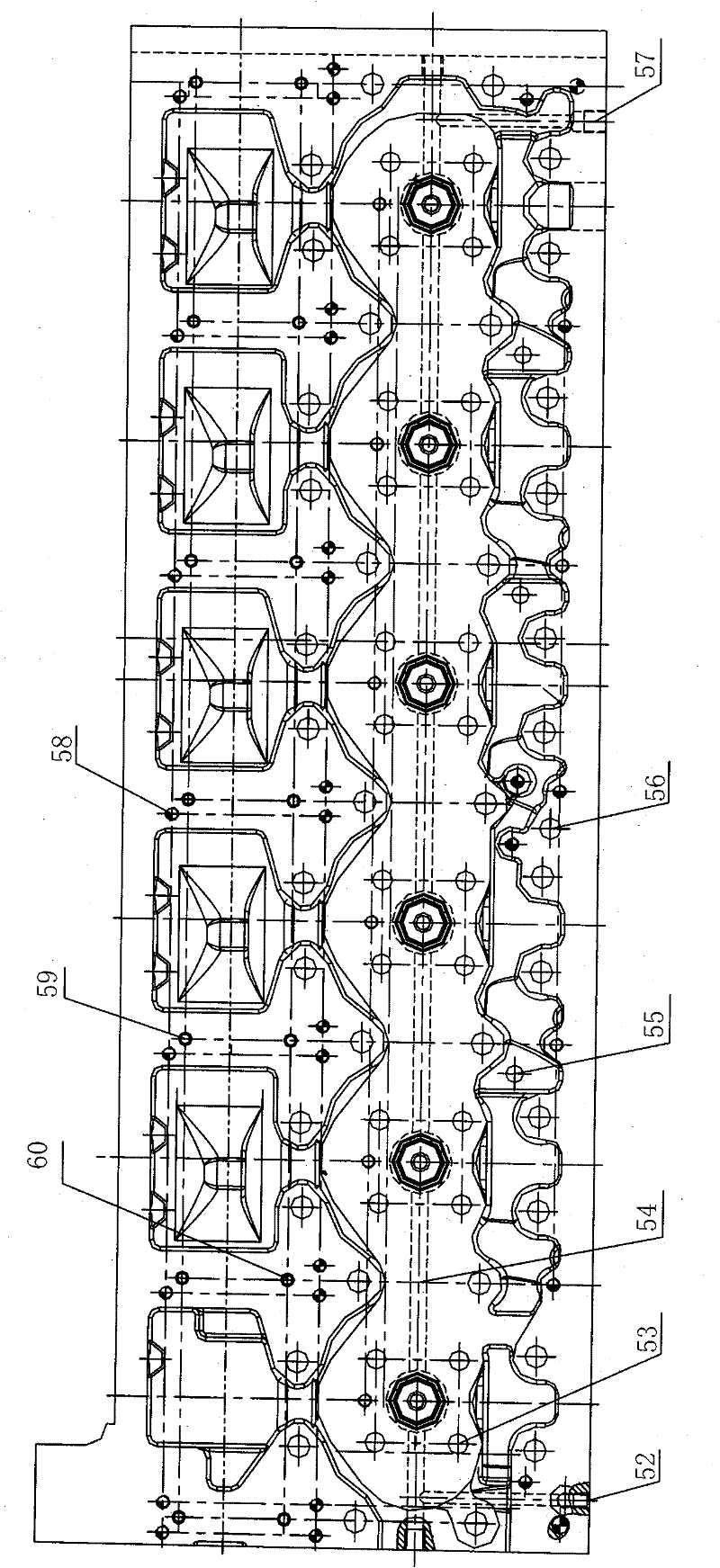

[0028] See figure 2 , image 3 with Figure 4 , That is, the central sectional structure diagram of the first cylinder of the present invention. In this embodiment, a cylinder center distance is 178 mm, cylinder diameter is 135 mm, stroke is 160 mm, displacement is 13.74-14 liters, medium-power inline six-cylinder electric The diesel engine integral cylinder head structure with 24 valves and overhead camshaft, mainly including 6 cylinder holes, cylinder head bolt mounting holes B01~B38, intake port 39, exhaust port 43, intake and exhaust valve seat Holes 45, 46, valve guide mounting holes 53, 12 sand cleaning holes 41, electronic control pump nozzle copper bushing installation hole 50, electronic control pump nozzle pressure plate installation hole 60, overhead camshaft bearing seat installation hole 58 and positioning pin Hole 59, thermostat installation hole 47, water through hole 48 and cooling water channels 49, 51 and other components. A first cylinder bore A01 and a sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com