Numerical control gear shaping, gear milling compound machine tool

A compound machine tool and gear milling technology, which is applied to gear cutting machines, gear tooth manufacturing devices, gear teeth, etc., can solve the problems of asymmetrical layout, inconvenient tool replacement, and affecting machining accuracy, so as to increase the scope of use and reduce equipment investment and the effect of the footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

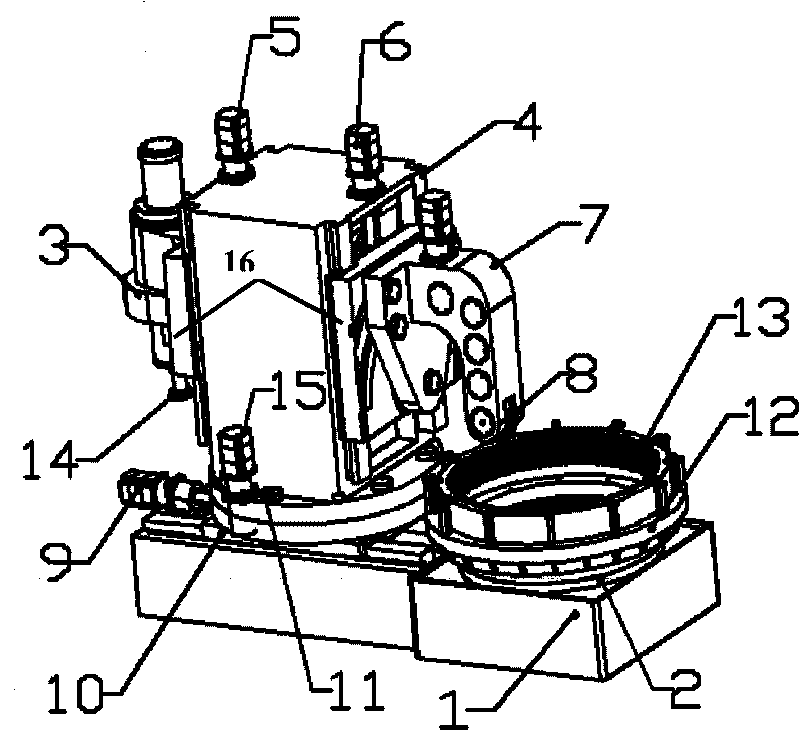

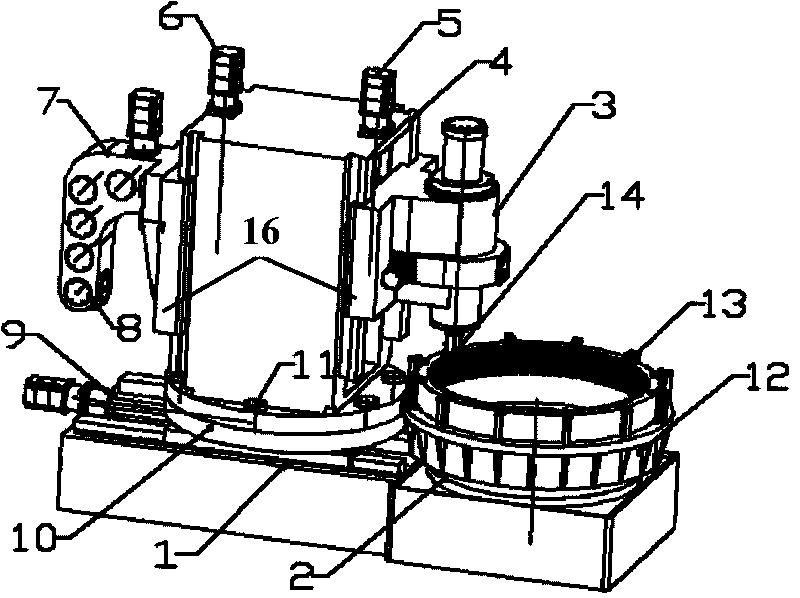

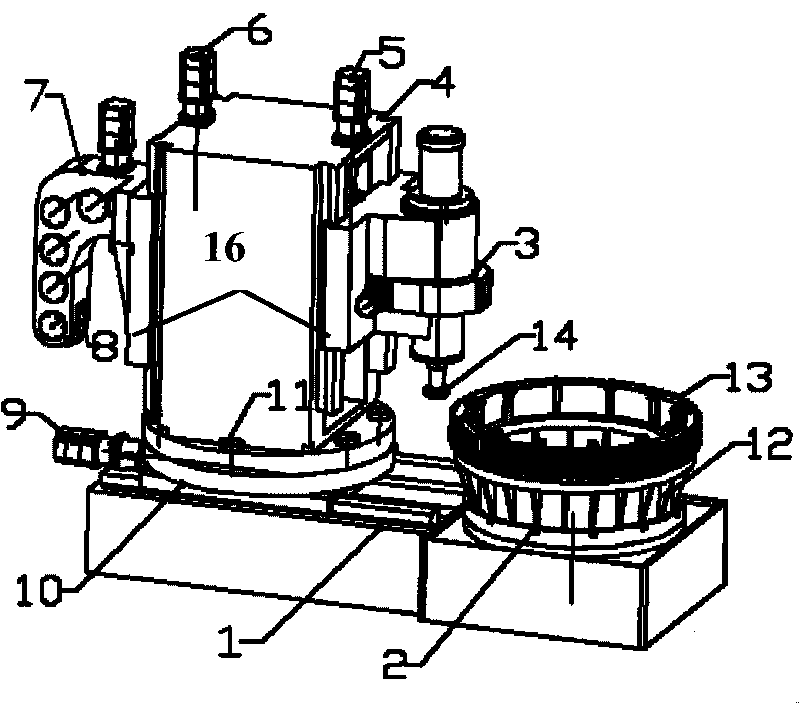

[0029] Below in conjunction with accompanying drawing, specific embodiment of the present invention is given in detail, wherein figure 1 It is a schematic diagram of the CNC gear shaping and milling compound machine tool for milling internal teeth; as shown in the figure, the CNC gear shaping and milling compound machine tool of the present invention mainly includes a bed 1, a CNC rotary table 2, a composite function column 4 and an installation knife The slide plate 16 of frame. The bed 1 supports the CNC rotary table 2 and the composite function column 4, wherein a replaceable gear-making fixture 12 is installed on the CNC rotary table 2, and the gear-making fixture 12 fixes the processed workpiece 13 and drives the processed workpiece 13 on the table Spin up.

[0030] The bed 1 has a sliding track, and the turret tool holder 16 is located on the sliding track. On each vertical surface of the column 4, a slide plate 16 of a tool holder capable of vertical movement is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com