Passivation process of citric acid and hydrogen peroxide of stainless steel

A technology of citric acid and hydrogen peroxide, which is applied in the field of metal surface treatment, can solve problems such as harsh operating conditions, harmfulness of passivation liquid to human body, and potential safety hazards, and achieve the effects of simple operation, reduced passivation cost, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

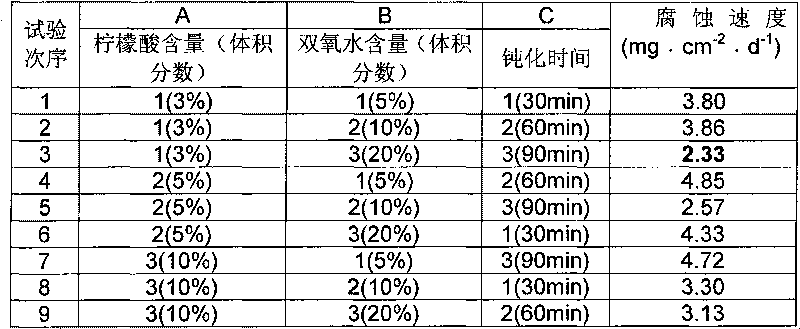

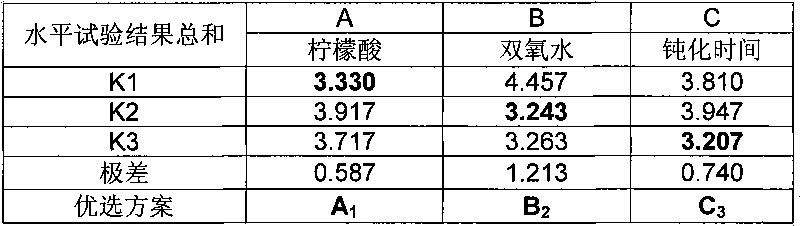

Image

Examples

Embodiment

[0024] The application examples are listed below to specifically illustrate the specific operation process of the present invention in the process of pickling and passivating stainless steel.

[0025] (1). Degreasing the treatment area.

[0026] (2). If there is grinding and polishing in the area to be treated, Cl should be used - Rinse the surface with water (such as deionized water) with a mass fraction not greater than 25 μg / g.

[0027] (3). Pickling (such as using 10% to 15% citric acid) stainless steel to remove surface oxide and rust.

[0028] (4). Select Cl - Rinse the surface with water (such as deionized water) with a mass fraction not greater than 25 μg / g.

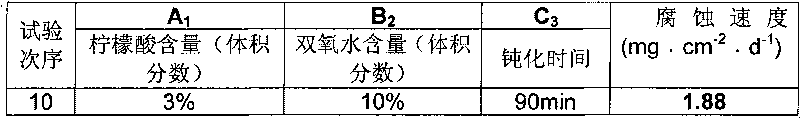

[0029] (5). According to the volume fraction of 3% citric acid, 10% hydrogen peroxide and 5% ethanol, a citric acid hydrogen peroxide passivation solution was prepared.

[0030] (6). Evenly spray or soak the prepared citric acid hydrogen peroxide passivation solution on the stainless steel surface, and passiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com