Waste tobacco leaf recycling method

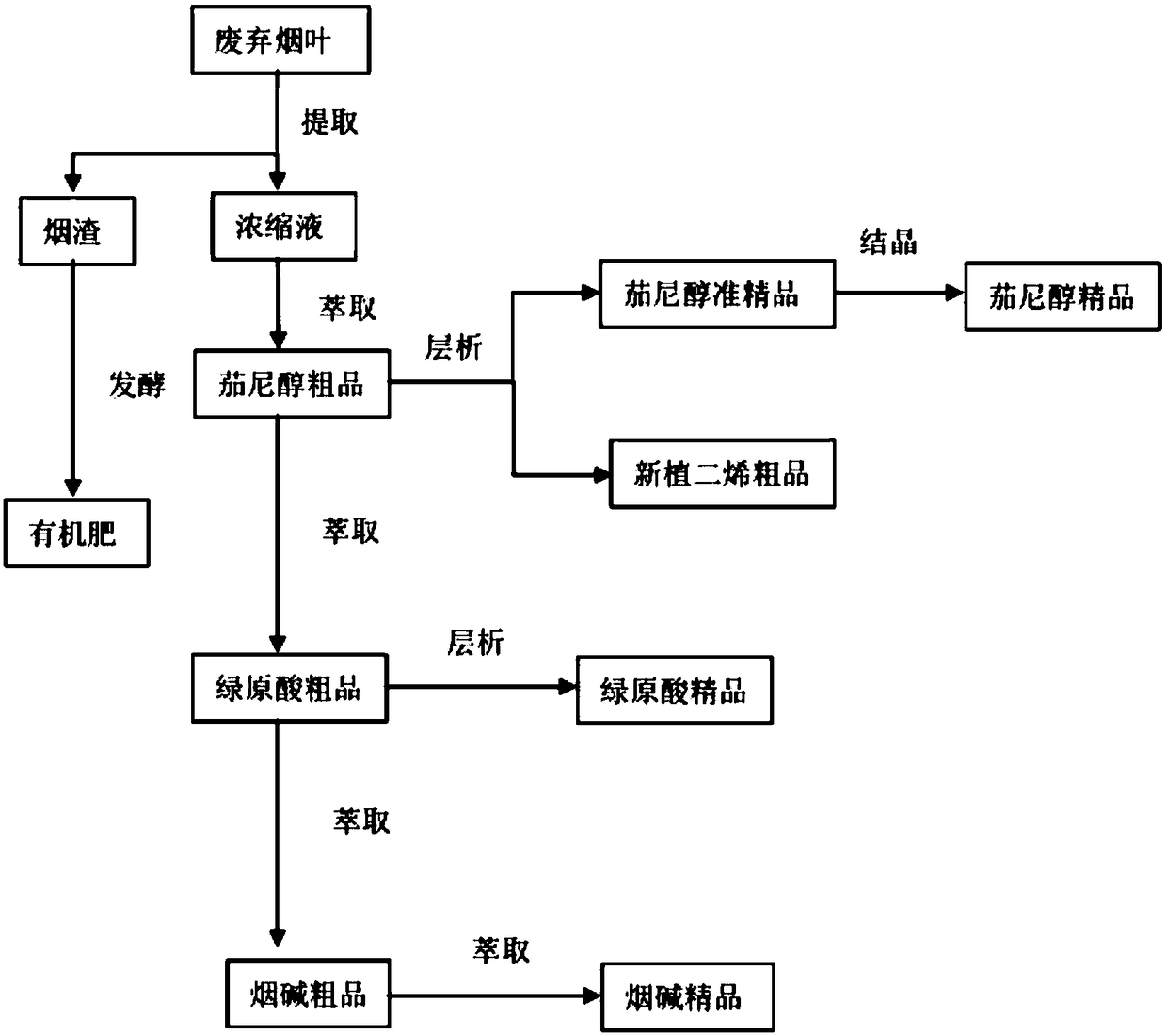

A technology for waste tobacco leaves and waste residues, applied in chemical instruments and methods, separation/purification of carboxylic acid esters, preparation of organic compounds, etc., can solve the problems of lack of large-scale comprehensive production technology of waste tobacco leaves, low extraction rate, and backward technology , to achieve the effects of good equipment adaptability, high product yield, and no discharge of toxic and harmful substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for recycling waste tobacco leaves, comprising the steps of:

[0028] (1) Extraction: Put the waste tobacco leaves in the extraction tank, add 90% industrial ethanol, heat to 70°C for 30 minutes, collect the extract, and pump it into the concentration tank; add 90% industrial ethanol to the remaining waste residue, repeat the above Step: Concentrate the obtained extract and recover ethanol, the vacuum negative pressure of the concentration tank is 1.0Mpa, the temperature is 60°C, and the concentration is concentrated to a density of 1.0g / cm 3 g / cm 3 , to obtain concentrated primary cream;

[0029] (2) preparation of solanesol:

[0030] A. Pump the concentrated primary paste into the reaction kettle, add 20% sulfuric acid aqueous solution to adjust the pH to 3, according to the mass ratio of the concentrated solution and petroleum ether is 1:1, add petroleum ether of equal quality and stir for 15 minutes to extract, and let it stand for 10 minutes. Pump the e...

Embodiment 2

[0049] A method for recycling waste tobacco leaves, comprising the steps of:

[0050] (1) Extraction: Put the waste tobacco leaves in the extraction tank, add 90% industrial ethanol, heat to 70°C for 40 minutes, collect the extract, and pump it into the concentration tank; add 90% industrial ethanol to the remaining waste residue, repeat the above Step: Repeat the above steps, concentrate the obtained extract and recover ethanol, the vacuum negative pressure of the concentration tank is 1.0Mpa, the temperature is 60°C, and the concentration is concentrated to a density of 1.2g / cm 3 , to obtain concentrated primary cream;

[0051] (2) preparation of solanesol:

[0052] A. Pump the concentrated initial paste into the reaction kettle, add 30% sulfuric acid aqueous solution to adjust the pH to 2, add petroleum ether of equal mass and stir for 20 minutes to extract, let stand for 10 minutes, and pump the extract into the concentration tank;

[0053] B. Concentrate the extract and...

Embodiment 3

[0070] A method for recycling waste tobacco leaves, comprising the steps of:

[0071] (1) Extraction: Put the waste tobacco leaves in the extraction tank, add 90% industrial ethanol, heat to 70°C for 60 minutes, collect the extract, and pump it into the concentration tank; add 90% industrial ethanol to the remaining waste residue, repeat the above Step: Repeat the above steps, concentrate the obtained extract and recover ethanol, the vacuum negative pressure of the concentration tank is 1.0Mpa, the temperature is 60°C, and the concentration is concentrated to a density of 1.2g / cm 3 , to obtain concentrated primary cream;

[0072] (2) preparation of solanesol:

[0073] A. Pump the concentrated primary paste into the reaction kettle, add 40% sulfuric acid aqueous solution to adjust the pH to 1, according to the mass ratio of the concentrated solution and petroleum ether is 1:1, add petroleum ether of equal quality and stir for 30 minutes to extract, and let it stand for 10 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com