Groove spacing accurately adjusting device in holographic grating manufacturing light path

A precise adjustment and holographic grating technology, applied in the spectrum field, can solve problems such as the inapplicability of the LOY mirror exposure optical system, and achieve the effects of shortening the adjustment time, improving the adjustment accuracy, and simplifying the adjustment steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

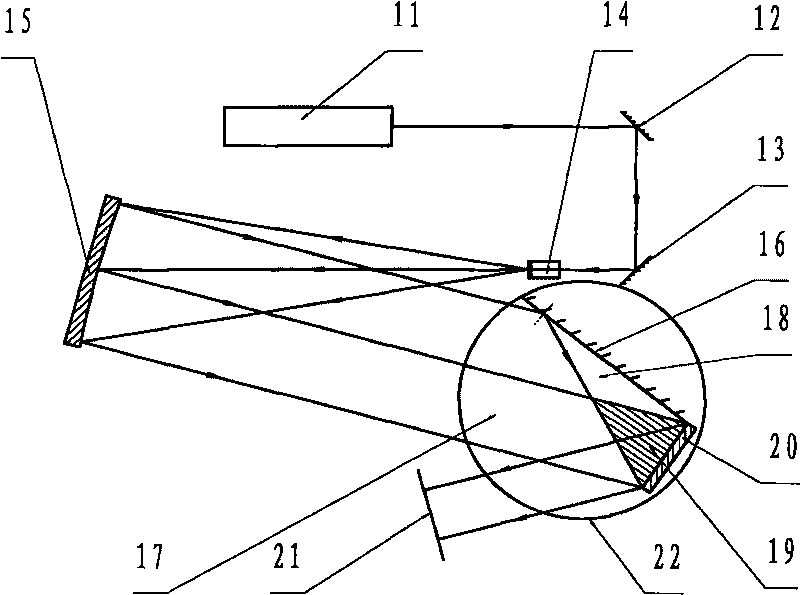

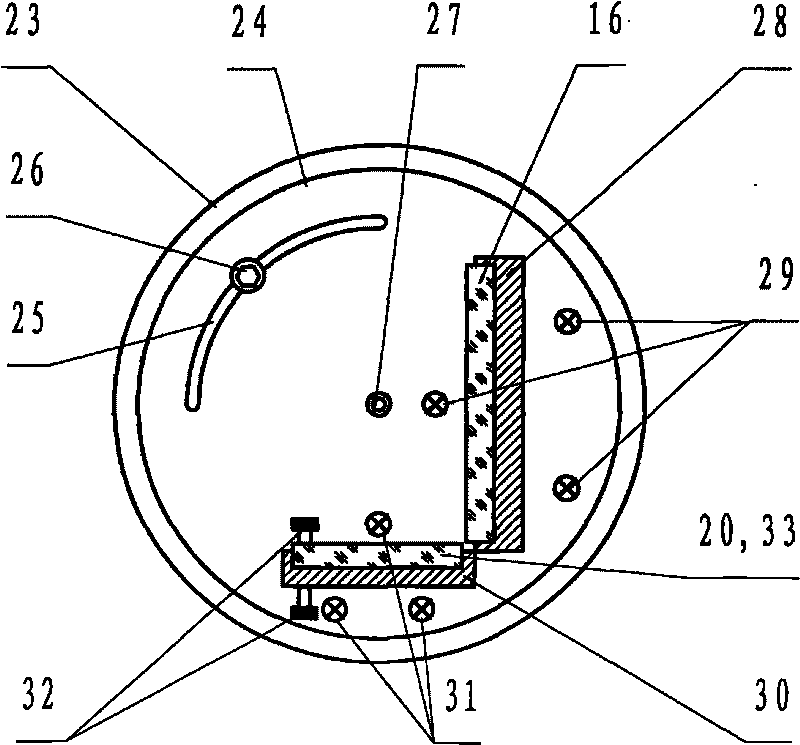

[0012] The invention according to figure 2 , 3 The structure shown in , 4 is implemented, wherein, the laser light source 11 adopts a krypton ion laser, the wavelength is 413.1nm, the first plane reflector 12 and the second plane reflector 13 are aluminum-plated reflectors on glass substrates, and the spatial filter 14 is composed of a display Composed of a micro-objective lens and a pinhole, the diameter of the collimating mirror 15 is φ320mm, the focal length is f=1.2m, the adjusting mirror 16 is an aluminum-plated mirror on a glass substrate, and the reference grating 20 needs to select a reflection grating with a standard reticle density according to actual requirements , the receiving screen 21 is made of ordinary white frosted glass, the grating substrate 33 is made of K9 optical glass, the photoresist coated on the K9 optical glass is Shipley1805 photoresist produced in Japan, and the device for accurately adjusting the line density of the holographic grating All mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com