Method for preparing carbon nanohorn

A carbon nanohorn and amorphous carbon technology, which is applied in the field of DC arc preparation of carbon nanohorn, can solve problems such as complicated operation, and achieve the effects of high purity, low production cost and simple equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

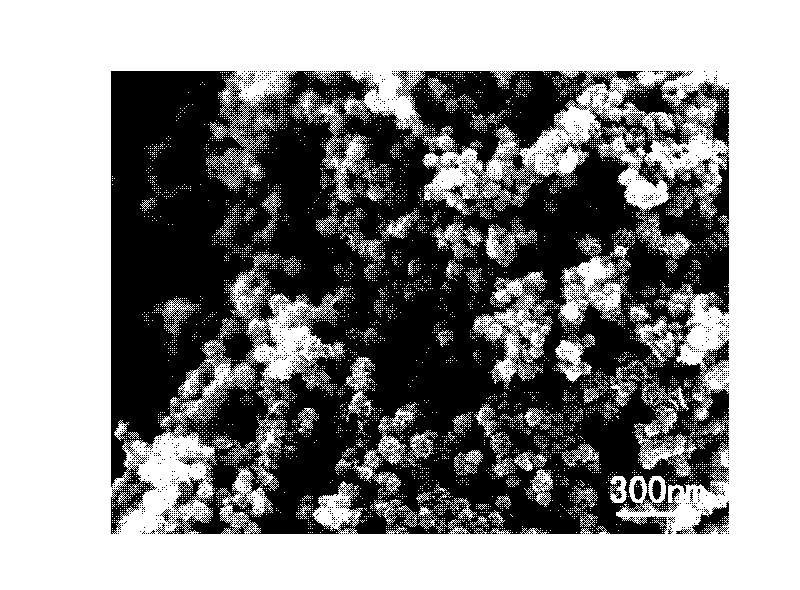

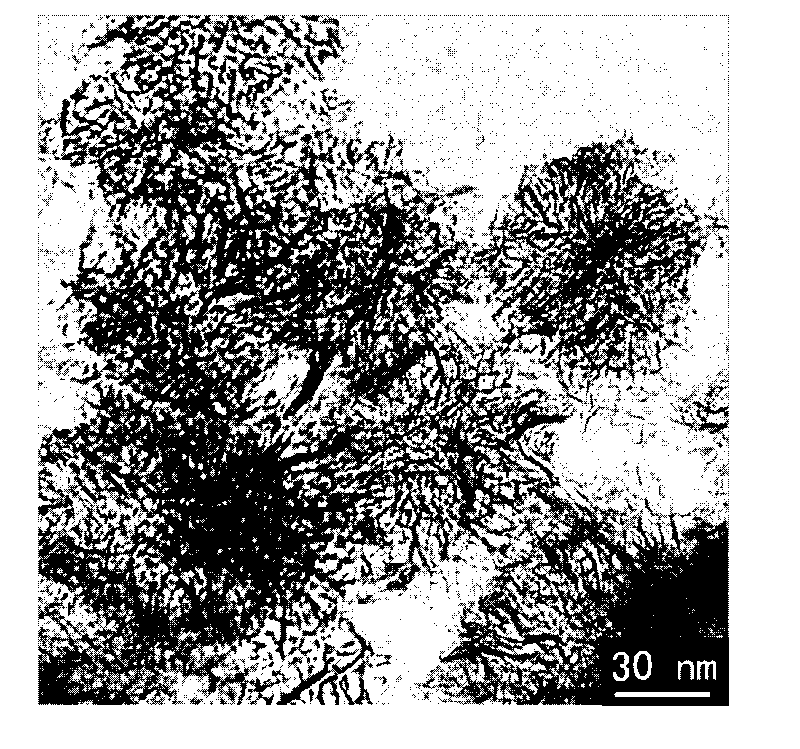

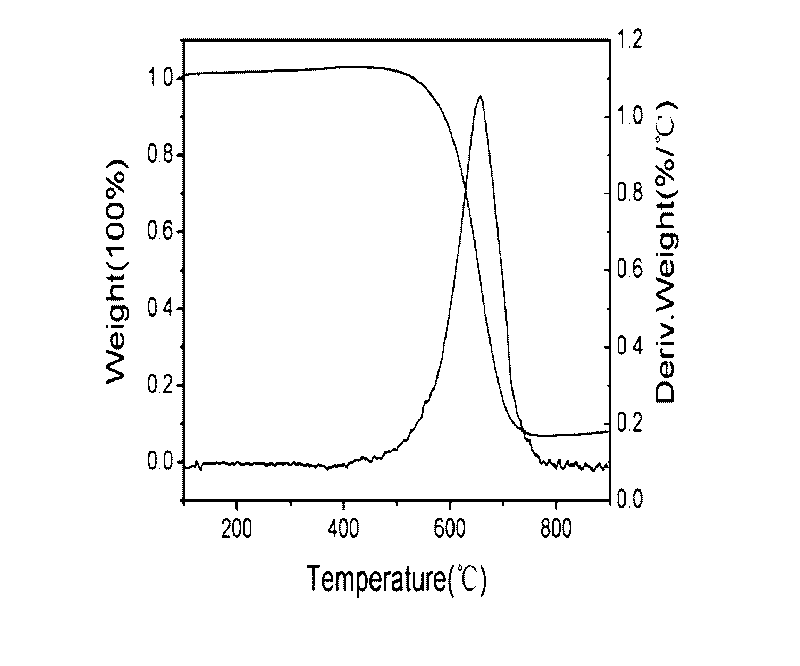

[0025] The electric arc furnace is used for direct current discharge, and the furnace wall of the electric arc furnace is cooled by circulating water. Spectroscopically pure graphite rods are used as the cathode and anode respectively, and the diameter of the graphite rods at both poles is 8 mm. Arc discharge was performed in an air atmosphere with a gas pressure of 380 Torr and a current of 120A. After the anode was consumed, the product was collected and burned in air at 450° C. for 1 hour to obtain dahlia-type carbon nanohorns with a purity of more than 94%. figure 1 It is a scanning electron micrograph of the obtained carbon nanohorn, and the balls in the figure are aggregates of carbon nanohorn, and the diameter is generally 50-80 nanometers. figure 2 The transmission electron micrograph of the obtained carbon nanohorn shows aggregates of carbon nanohorns and a pyramid-like structure at the end of the carbon nanohorns. image 3 is the thermogravimetry and differential ...

Embodiment 2

[0027] The electric arc furnace is used for direct current discharge, and the furnace wall of the electric arc furnace is cooled by circulating water. Spectroscopically pure graphite rods are used as the cathode and anode respectively, and the diameter of the graphite rods at both poles is 8mm. in CO 2 Arc discharge was performed in the atmosphere, the gas pressure was 380 Torr, and the current was 120A. After the anode was consumed, the product was collected and burned in air at 450° C. for 1 hour to obtain bud-type carbon nanohorns with a purity of more than 94%. Figure 4 It is a scanning electron micrograph of the obtained carbon nanohorn, and the balls in the figure are aggregates of carbon nanohorn, and the diameter is generally 50-80 nanometers. Figure 5 It is a transmission electron micrograph of the obtained carbon nanohorn, and it can be seen that the aggregation of the carbon nanohorn and the ends of the carbon nanohorn are relatively smooth.

Embodiment 3

[0029] The electric arc furnace is used for direct current discharge, and the furnace wall of the electric arc furnace is cooled by circulating water. Spectroscopically pure graphite rods are used as the cathode and anode respectively, and the diameter of the graphite rods at both poles is 8mm. Arc discharge was performed in a CO atmosphere with a gas pressure of 500 Torr and a current of 80A. After the anode was consumed, the product was collected and burned in air at 450° C. for 1 hour to obtain bud-type carbon nanohorns with a purity of more than 94%.

[0030] Example four

[0031] The electric arc furnace is used for direct current discharge, and the furnace wall of the electric arc furnace is cooled by circulating water. Spectroscopically pure graphite rods are used as the cathode and anode respectively, and the diameter of the graphite rods at both poles is 8mm. in CO and N 2 Arc discharge was performed in a mixed atmosphere (the volume ratio of the two was 1:2), the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com