Biological aerated filter with large particle-size and light-weight filler at surface layer

A technology of biological aerated filter and lightweight filler, which is applied in the direction of sustainable biological treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., and can solve the problem of increasing backwash water consumption and reducing the biomass of the filler layer , affect the treatment effect and other issues, to achieve the effect of prolonging the backwashing cycle, slowing down the accumulation speed, and saving backwashing water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

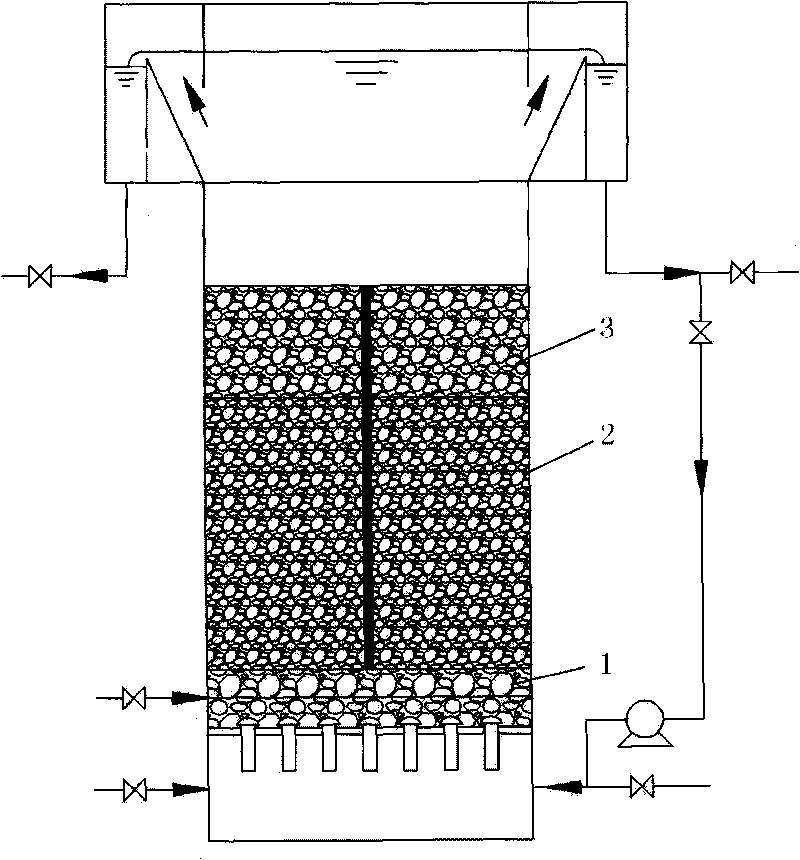

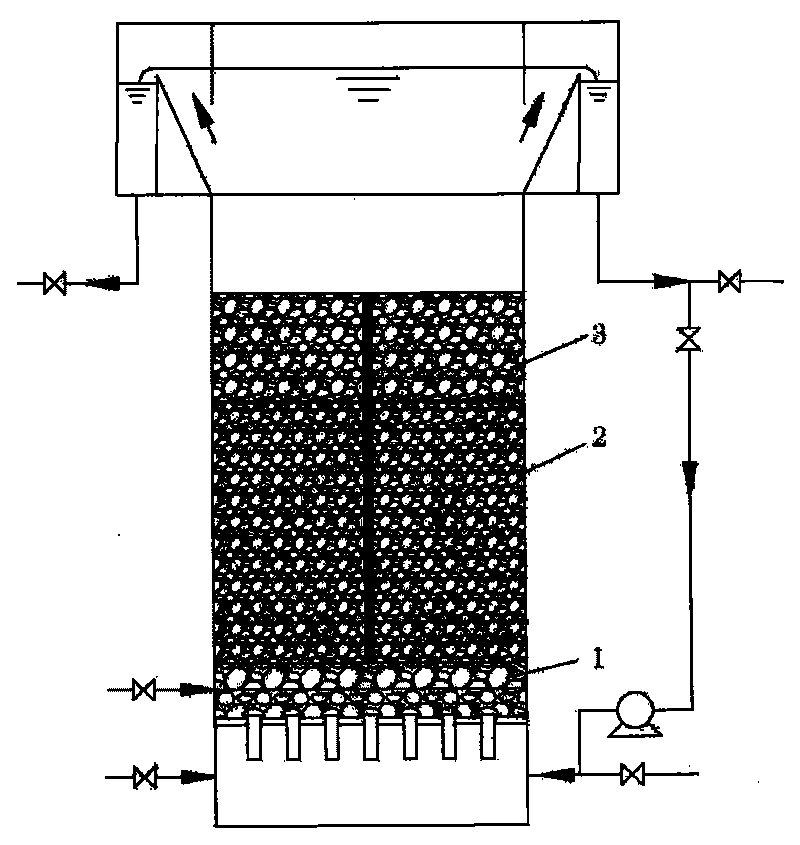

[0012] Such as figure 1 As shown, a biological aerated filter with large particle size and lightweight filler on the surface layer, its filter device is arranged with a supporting layer 1 with a large particle size of 800mm and a filter material layer 2 with a diameter of 2000mm from bottom to top. A lightweight filler layer 3 with a large particle size of 1000 mm is provided. The large particle size lightweight filler layer 3 is composed of volcanic rock or anthracite or artificial ceramsite or any mixture of the above materials with a particle size of 6-8 mm. The filter material layer 2 is composed of quartz sand with a particle diameter of 4-5 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com